JDR technology connects the global offshore energy industry, enabling vital control and power delivery to offshore oil, gas and renewable energy systems. Many of the world’s major energy companies and subsea service providers trust JDR subsea control umbilicals and subsea power cables to offer outstanding performance and reliability in the world’s harshest offshore environments.

JDR delivers world-class subsea products and is fully committed to lifecycle customer service. The company has a proven track record of meeting and exceeding client expectations.

Subsea production umbilicals, umbilical termination assemblies, electric / hydraulic flying leads, subsea isolation valve umbilicals

JDR umbilicals are designed to operate long-term in challenging and dynamic subsea environments in a wide range of water depths. They provide critical power, control and monitoring links, which connect multiple elements of an offshore oil and gas field. Customised JDR umbilical and umbilical system properties can include:

- Steel tube or thermoplastic

- Ultra-long length electric power cores, which significantly reduce the number of core splices

- Conduits for hydraulic fluids, process chemicals or electrical cables that transmit power and enable communication across any gas or oil field

- High pressure / high temperature systems and chemical injection

- Subsea umbilical termination assemblies (SUTA), subsea isolation valve umbilicals (SSIV), hydraulic flying leads (HFL), electrical flying leads (EFL), stab plates and connector sourcing and supply

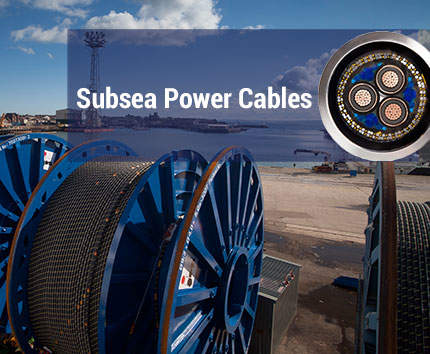

Subsea power cables (SPCs)

JDR’s subsea power cables (SPCs) for oil and gas are designed to operate in dynamic subsea environments. They cover great distances and last for many years. We provide turnkey solutions, developing complete packages that incorporate our subsea umbilical termination assemblies (SUTA) and installation support services.

We also offer a range of subsea power cable solutions that can include fibre optic communications and fluid transfer between fixed and floating offshore installations and subsea infrastructures.

The JDR engineering team develops SPCs with:

- Flexibility in material selection and configuration of manufacturing processes; e.g. a range of polymer options

- Three-phase AC systems with a voltage range of 1kV to 74kV

- Both ‘wet’ and ‘dry’ design types using either EPR or XLPE three-layer insulation systems

- A range of armouring options, from single to multi-layer

- Coilable and non-coilable designs

- Termination design and fitting for topside and subsea connections

- Assembly, qualification and testing in-house to avoid risk of commissioning delays

Our renewable products connect power generation devices, such as wind turbines, within an offshore wind farm, and ensure power is transferred to an offshore or onshore substation.

We develop comprehensive systems and also provide inter-array cables complete with our patented hang-off and termination products. We offer fully verified electrical and optical packages for a range of operational requirements, and our subsea cable joints are fully compliant to all industry standards.

Intervention workover control systems (IWOCS)

JDR is a global market leader in IWOCS umbilical systems. Our design team recently led the development of new open water umbilical technology that significantly reduces offshore operating costs. Along with our topside wellhead umbilicals, we can provide a complete turnkey solution.

Our range of superior subcomponent hoses, and our knowledge of hose and cable technology, enables clients to work as partners in the development of systems that are uniquely tailored to specific requirements. JDR has also developed specialised test equipment to simulate deployment stresses on the IWOCS umbilical and validate the product prior to final manufacture and assembly.

Offshore service and field maintenance support

JDR’s global offshore services and field maintenance division offers full product lifecycle support, from pre-commissioning to aftermarket, to maximise your investment and lower the total cost of equipment ownership. Our network of technicians and service support capabilities can be contacted 24/7, and our staff and equipment can be mobilised at short notice.

We manage customer projects for JDR and non-JDR products, on or offshore, including the provision of staff, test equipment, training and supervision during customer installation, project pre-commissioning and cable handling. Our integrated approach to lifecycle service includes strong maintenance and inspection routines that incorporate product lifecycle preventative maintenance and assurance programmes.

Manufacture, sales, engineering and service locations

JDR serves its international offshore oil and gas customers through well-equipped facilities in the UK, the US and Thailand.

- Hartlepool, UK – an advanced facility with a cable manufacturing plant capable of delivering individual cables weighing up to 4,000t; direct access to the North Sea

- Littleport, UK – engineering design, project management, R&D, IWOCS production and manufacture of specialist components and subsea production umbilicals and power cables up to 100t

- Houston, US – assembly, integration and testing of umbilicals, reelers and associated packages; project management and engineering support; offshore commissioning, testing and repair work

- Sattahip, Thailand – project management, manufacturing and load-out

Health, safety and engineering

JDR is fully accredited to ISO9001 and can build systems in accordance with the latest ISO 13628-5/API 17E specs. We offer full dynamic analysis, fatigue analysis and seabed stability analysis for all of our subsea products, to prove the suitability of our designs for the full lifecycle of operation.

Our field service technicians are trained in all aspects of risk assessments and basic offshore safety induction and training courses, and are HUET and EBS approved and UK BOSIET OPTIO approved.