Oerlikon Metco enhances components with innovative coating solutions that improve performance and increase efficiency and reliability. We provide a comprehensive global manufacturing, distribution and service network catering to aerospace, power generation, automotive, oil and gas and other specialized markets.

Oerlikon Metco has a large variety of coating and surface solutions and technologies to suit each client’s equipment, including thermal spray, plasma heat treatment and laser cladding services.

Functional coating solutions

The objective of a coating is to protect the base material of components used in offshore environments against seawater corrosion, heavy wear, abrasion, galling and slurry erosion. Coating solutions considerably increase the lifetime and efficiency of downhole tools, drill parts and valves, as well as reduce replacement and repair costs.

Riser tensioners

It is essential that riser tensioner rods are adequately protected against the corrosive effects of saltwater erosion and deterioration from rugged environments to maintain performance. Oerlikon Metco’s coatings ensure smooth piston actuation, even after the rod has experienced prolonged exposure to saltwater. Other coatings, using thermal spray materials, can be applied using HVOF or atmospheric plasma spray equipment and machined to achieve a smooth finish.

Drill parts

Drill parts must resist extreme loads, which require weld surfacing processes to increase abrasion and erosion resistance. Surface protection with welding rods for oxyacetylene welding, cored wires for MIG welding and carbide materials, PTA and laser cladding blend materials result in longer service life and reduced repair costs.

Oerlikon Metco has a large variety of coating solutions to suit each client’s equipment, including plasma heat treatment, laser cladding services, diamond-like carbon coatings, and physical vapour deposition and thermal spray coatings.

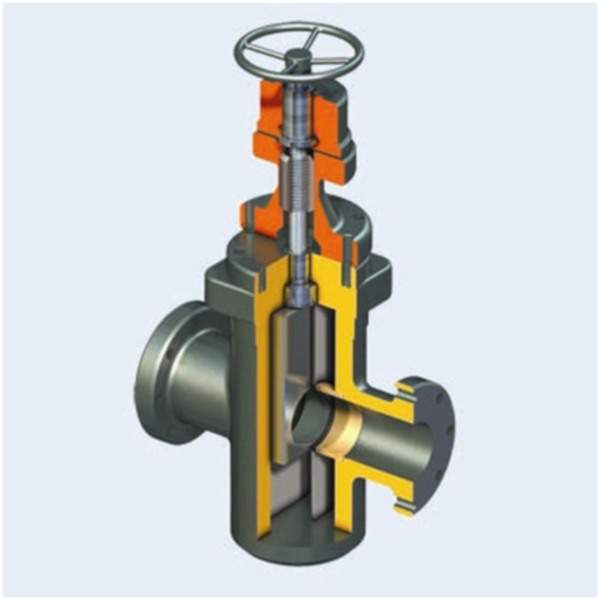

Gate valves

To prevent leakage or faulty activation, thermal spray coatings are applied to gates and seats. Oerlikon Metco’s tungsten and chromium-based carbide materials ensure protection from galling, corrosion and wear. Applying thermal spray coatings using HVOF gas or liquid fuel equipment and materials result in dense, homogeneous coatings with good bond strengths.

Mandrels / stabilisers for supporting drill string tools

Our tungsten carbide materials are designed to produce coatings that are wear-resistant in a seawater environment and corrosion resistant in alkaline or acidic environments. Surfaces of mandrels / stabilisers that support essential drill string tools benefit from increased drilling uptime, extended service life and reduced replacement costs by using thermal sprayed coatings.

Coating services for offshore structures and equipment

Oerlikon Metco’s coating services offer approved solutions for a broad range of industrial components. We operate well-equipped processing facilities for thermal spray, laser cladding, PVD, diamond-like carbon coatings, plasma heat treatment pre-and post-machining operations, laboratory analysis and quality control.

Coating materials

Our team of engineers design surface technologies that include powders and wires for thermal spray coating applications and materials for hardface welding, PTA, laser cladding, brazing, electronic fillers and pack diffusion.

Coating equipment for thermal spray and laser cladding

Our coating systems and equipment for thermal spray and laser cladding are customised to meet the specific requirements of various industries. The equipment is sensitive to important factors such as workpiece geometry, substrate material, desired surface properties and required production rate.

With our broad range of products and services and our global presence, Oerlikon Metco enables customers to extend component lifecycles, reduce downtime and increase productivity.