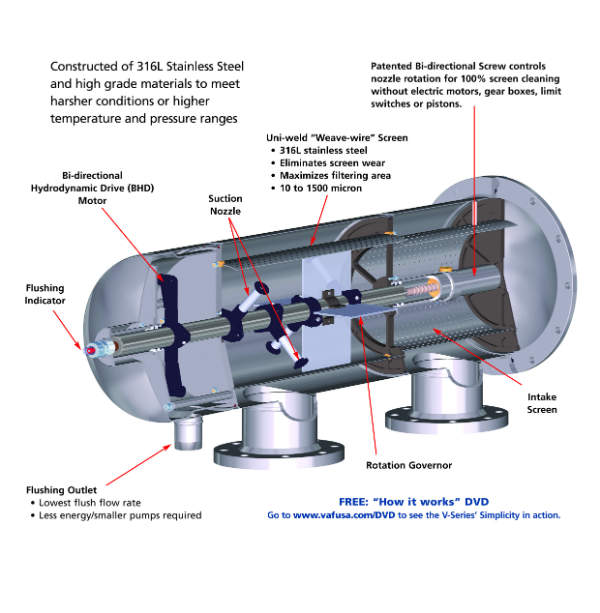

Established in 1980, VAF Filtration Systems™ has been providing filtration solutions worldwide for more 30 years and built its business model on simplicity, quality, and integrity. Our flagship product line, the V-Series™, are automatic screen filters used ‘Wherever Water Flows’ and can remove suspended solids from 10µ to 1,500µ.

Filters for reuse of industrial water

Individual filters and pre-assembled filtration systems are used in applications for industrial water reuse including groundwater re-injection (Frac water), water and wastewater, cooling towers, seawater, river intake water, well water and groundwater.

As the V-Series filters are manufactured in the US, they qualify for Made in America funding. They also qualify for LEED points due to the unique water saving features and energy conservation.

The standard V-Series filters are competitively priced while manufactured in 316L stainless steel. They can also be ordered to meet ASME Pressure Vessel Code requirements (ASME Boiler and Pressure Vessel Code, Section VIII, Division 1) if necessary. In addition, the stainless steel filter bodies come with a five-year body warranty against leaks. The patented Bi-directional Hydrodynamic Drive (BHD) design does not require electric motors, limit switches, gearboxes, hydraulic pistons or any external shaft seals. The cleaning cycle of each filter takes less than 15 seconds and does not interrupt flow during the filtration process.

Filters for state-of-the-art automatic self-cleaning

The patented BHD improved screen cleaning efficiencies result in:

- 100% screen cleaning with controlled suction nozzle rotation

- Flush waste less than 1% of system flow

- 70% fewer moving parts

- Priced competitively against all carbon steel body filters

- Individual flow rates from 7m³ to 2,274m³/hr (30gpm to 10,000gpm)

- Made in the US

- Lower maintenance requirements

Portable skids for Frac water

VAF specializes in the Engineering and Manufacture of automatic self-cleaning individual, modular and skid mounted filtration systems that include integrated controls and valves. The V-Series automatic self-cleaning filter skid for Frac water (V-Series-FS) has been designed for easy portability; available in various configurations for local or remote oil field locations where the filtration skid needs to be relocated.

Its unique design not only provides for quick piping hookups and disconnects, but includes a "roll bar" frame that protects the filter, control and piping from damage during relocation. The V-Series 316L bodies are horizontally designed for ease of maintenance and simpler operation

with fewer moving parts.

"VAF is successfully working with all major oil companies to improve Frac water quality before being re-injected," said Steve Springer, VP. "This process is essential in helping to make the US less reliant on foreign oil.

Frac water reinjection systems

The V-FS filter skid is ideal for Frac water re-injection systems that require reduction or elimination of ‘consumable’ cartridge or bag filtration. The 316L stainless steel, multi-layered filtering screen utilizes a ‘Uni-weld, Sintered’ technology that maximizes open area, as well as the removal of organic and inorganic particulate from the screen. Inlet / outlet flange sizes can be specified to meet existing field piping.

Please do not hesitate to contact us if you need assistance with filter or system application and design assistance from one of our experienced application engineers.