Welding Alloys is renowned for its expertise in designing and manufacturing machines and consumable solutions, tailored to the global offshore industry.

The Welding Alloys Group orientates all its economic and strategic choices towards the long-term growth of the company. Innovation is the key word; defining our approach and developing solutions to meet our customers’ needs.

Covering more than 150 countries and territories throughout a network of over 30 subsidiaries, Welding Alloys is able to utilise its 1,200+ employees and specialists, offering an unrivalled service across the globe.

Reliable solutions for automated offshore welding

Welding Alloys pioneered the design and manufacture of automated welding equipment, continually improving design and build quality with over 40 years of experience. The range of automated welding equipment and consumables offered puts performance and reliability at the welder’s fingertips.

Welding Alloys offers welding equipment and consumables tailored to individual needs, ideal for handling the different types of demanding welding processes required in offshore fabrication. These include:

- Shielded metal arc welding (SMAW)

- Submerged arc welding (SAW)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Flux-cored arc welding (FCAW)

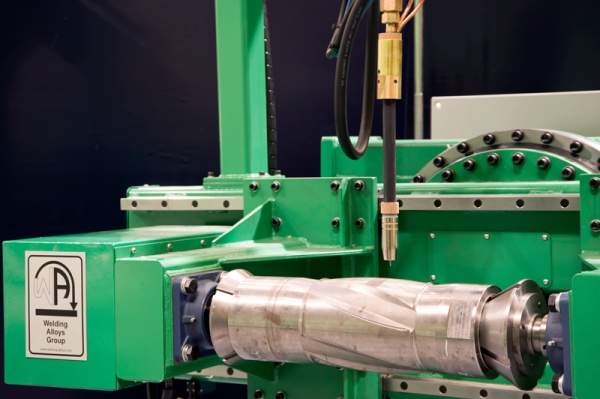

Automated welding machines

The equipment offered by Welding Alloys supports welding operations throughout the offshore industry. Our control technology, D3-Touch™, allows the simple setup and continuous welding of bores, pipes, valves and stabilisers with exceptional quality and precision, eliminating manual welding operations.

Offshore fabrication must comply with industry standards and approvals. The engineers at Welding Alloys are highly suited to work with teams and companies wherever they may be, in order to develop the best processes and procedures for individual company requirements, ultimately lowering fabrication costs and increasing efficiency.

The MultiSurfacer™ XT orbital welding machine has been designed and developed through Welding Alloys’ continued product development programme and in-depth product knowledge. This machine has been developed to use a hot wire TIG process for cladding bores, blocks and valves, utilising our innovative bore-to-bore software and arc voltage control (AVC).

Welding Alloys MultiSurfacer™ ST stabiliser welding machine is designed specifically to provide the automated welding of drill stabilisers used for applications in soft-to-medium hard formation holes in the oil and gas sectors. Through the use of the Welding Alloys range of consumables and flux-cored cladding wires, a high-quality, defect-free weld can be achieved on stabilisers, offering a superior level of wear resistance.

Welding consumables for offshore applications

In addition to an impressive history of machine building and supply, Welding Alloys offers an all-encompassing range of consumables designed to complement each machine and process, covering the entire range of base materials and filler metals for offshore applications.

Unalloyed / high strength

- ROBOFIL R 71: E71-1(5)MJ H4

- ROBOFIL R Ni 1 + R Ni 1 SR

- ROBOFIL R 690

Creep resistant up to 600°C

- ROBOFIL M Mo: E80C-G H4 M (B) CrMo1 and M (B) CrMo2

- ROBOFIL B P91: E90T5-G H4

Austenitic

- TETRA 308L, 316L, 308H, 309H, 310H, 347H

Soft martensitic materials

- CHROMECORE M/B 13/4; B 13/6

Nickel based up to 1,100°C down to -164°C

- GAMMA 182 NiCrFe-3 / GAMMA 182-E

- GAMMA 4648 NICrFe-2

- GAMMA 625 NiCrMo-3 / GAMMA 635-E

- GAMMA V 625, CRYO, 825

Duplex, lean-duplex, super-duplex

- TETRA V 22 9 3L-G, V LD62-G, V D57L-G, V, S, SB

- TUBE S 22 93L-G, LD62-G, D57L-G

With headquarters in Cambridgeshire, UK, Welding Alloys has machine fabrication and wire production locations worldwide, offering a global distribution and support network.

For more information about Welding Alloys, its services and products, please visit the company’s website or use the forms on this page.