Logistics excellence in an upstream oil and gas industry is today measured based on two critical parameters:

- Operational safety and compliance

- Optimized and cost-effective supply chain

To achieve this it takes an approach substantially more comprehensive than dozens of different applications and spreadsheet solutions stitched together. Additionally, it requires a pro-active approach that brings offshore and onshore logistics customers and their service providers together to enjoy full-scope logistics spanning air, marine and land operations and infrastructure support.

iLogistics is a comprehensive logistics solution, tailor-made for the upstream oil and gas industry. As an off-the-shelf logistics software that has been proven commercially, iLogistics integrates end-to-end people and material logistics management for global and regional upstream operations.

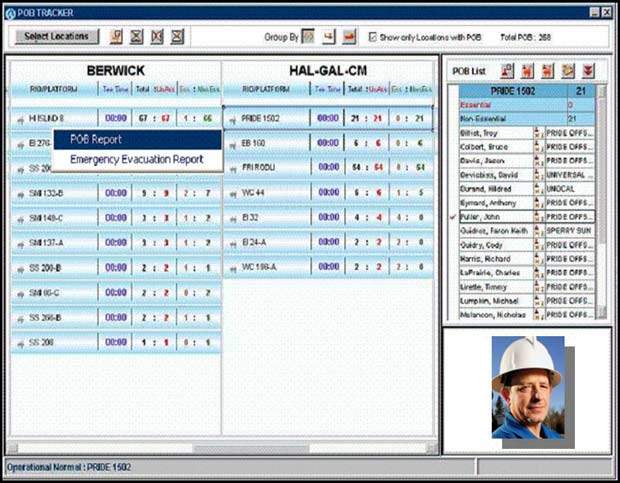

Offshore operational safety and compliance systems

Safety in the workplace is emerging as one of the key areas of risk management and regulatory compliance in exploration and production companies. Statistics from the industry reveal that for every 10,000 unsafe acts there are 1,000 near misses or incidents that require first aid, 100 restricted work cases requiring medical treatment only, ten lost-time accidents and ultimately one fatality.

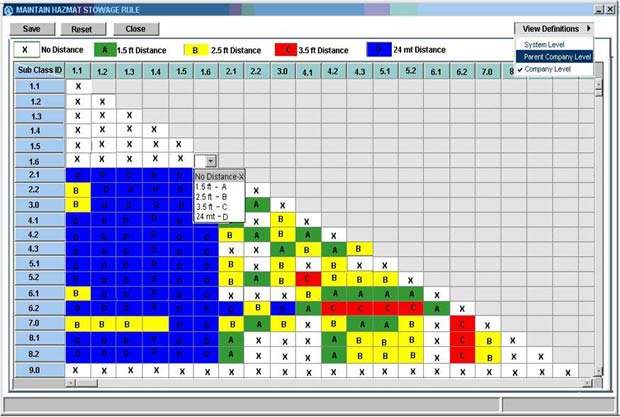

This trend is influencing the way the industry looks at traditional systems for monitoring environmental health and safety compliance systems. New generation systems need to ensure that:

- Offshore workers meet adequate training requirements for their offshore duty

- Logistics resources meet required technical compliance before take off

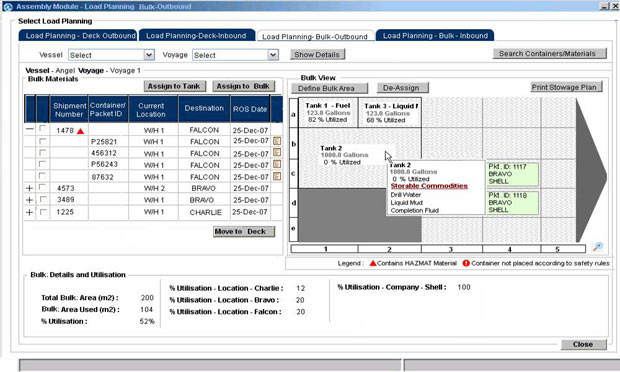

- Materials required for delivery are classified and loaded as per HAZMAT standards

- Efficient emergency evacuation planning is undertaken through all operational phases

- Enterprise-wide visibility is provided into incidents and trends

- Corrective actions can be easily taken during compliance deviations, etc.

iLogistics offers simple and state-of-the-art features that enable oil and gas companies to stay on-track in their effort to establish and implement measures for safety and environmental protection.

Optimized and cost-effective supply-chain logistics management

Upstream offshore and onshore logistics management is challenging due to the rising cost of oil prices, emphasizing the need for cost-effective operations. The importance of optimized logistics management is therefore to be highlighted since it accounts for 15%-20% of the operating expenditure of an oil and gas company. In today’s environment, breakdown of logistics operations even for a single hour can cost the value chain over $1 million, on average.

Large, integrated oil companies incur an operating expenditure of over $30 billion in today’s economic scenario. Even a 1% saving could be $30 million a year. iLogistics is maintainable at a low TCO for such large, integrated oil companies.

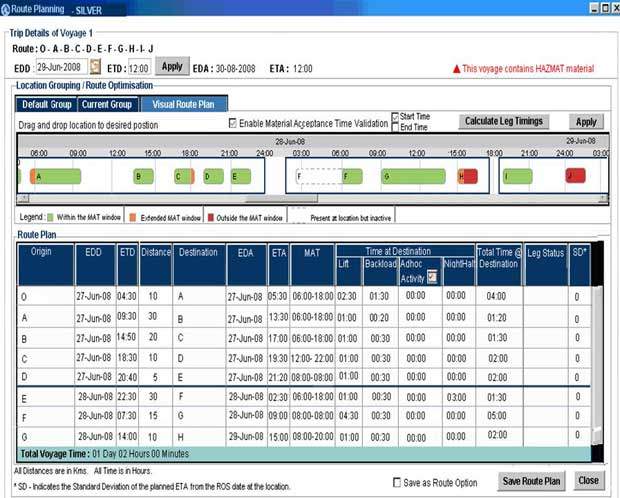

iLogistics has delivered over 100% ROI within the first one-and-a-half years of implementation. Supporting sharing of resources, long-term planning options, automation of routine processes, route optimization techniques, etc. are a few key functionalities that have enabled significant reduction in logistics cost and improved operational efficiency.

Integrated people and material logistics management – offshore and onshore

In an article published in the first 2009 issue of WorldExpro, Dirk Kramers (global discipline head of logistics and production supply chain at Shell International E&P) stated that: “There is at present no other system available that connects people and materials movement by aviation, marine and land in one piece of software”.

Both people and material logistics functionalities are designed to function in an integrated fashion and are fundamental to all four modules of the system, named Aviation, Marine, Land and PoB.

All four modules are available as standalone modules and as an integrated system. The system is capable of integrating with a number of systems, including third-party ERP systems such as SAP, JDE, hardware devices such as smart card systems or RFID devices and also back-end technology components such as business intelligence and data-warehouse systems.

Through robust interface capabilities, iLogistics enables oil and gas operators to adopt a collaborative working model with other participants of the value chain such as logistics service providers, material vendors and freight forwarders.

Advantages of integrated logistics software

A few of the key benefits derived by major oil companies who have implemented iLogistics include:

- Improved safety through improving safe movement of people and materials to and from locations

- Reduced risk by responding faster to un-planned events, crisis and incidents

- Optimized cost through efficient management of non-productivity / delays / revenue loss

- Improved planning through better forecasting and more control over resources and materials through optimization

- Increased visibility through comprehensive tracking functionalities

iLogistics is undergoing a number of enhancements, and has the potential to establish itself as a standard in the industry.