The global pandemic has brought with it a surge of QR codes appearing everywhere for people to find out the latest information or register details when visiting a public place. They can be easily interacted with by using a smartphone camera.

These unique tags have different uses underwater in the energy sector. QR or Quick Response codes are 2D barcodes that can link unlimited information such as text, images or website URLs, all within a relatively small space.

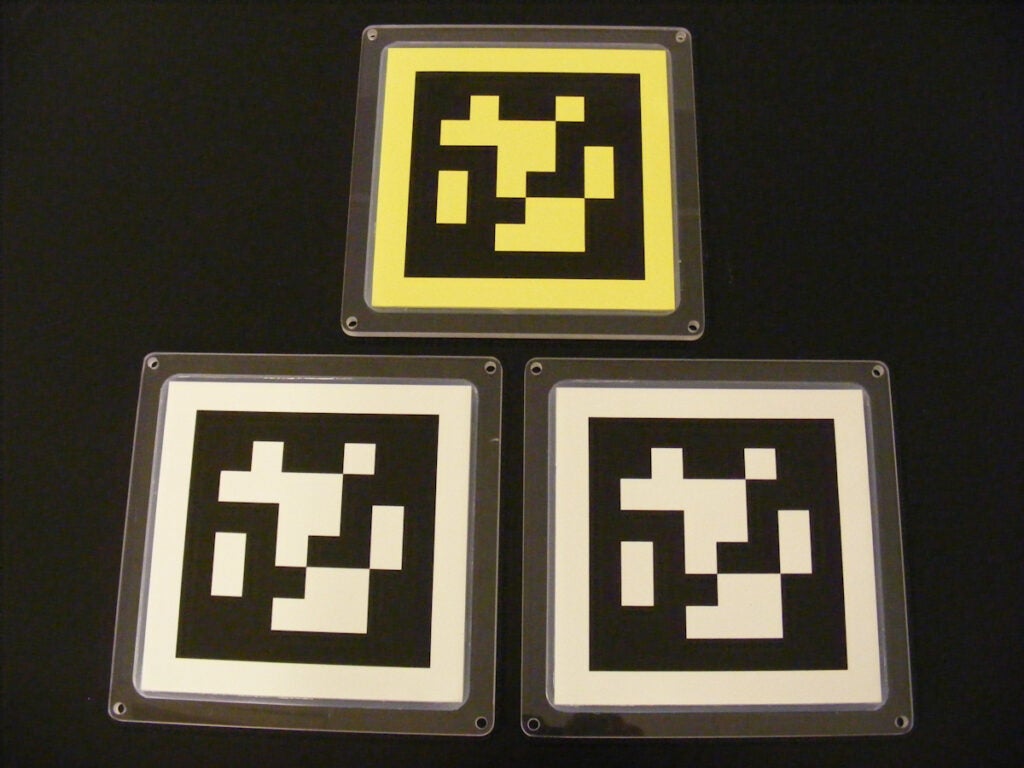

ArUrco is an open-source library for camera post estimation used by ROVs and positional survey equipment. This uses binary squares with a wide black border and inner matrix which determines the ID.

While Target IDs markings are specifically designed for detection by surveys, photographic or video capture. These help the equipment identify the area quickly and record the necessary data with ease.

All of these can be attached to subsea hardware onshore and offshore providing identification markers for photo and videography AUV (autonomous underwater vehicle) or ROV (remotely operated vehicle) equipment.

“In an underwater environment, it’s obviously a lot more challenging depending on the survey or the camera equipment that they have. So, it’s about trying to get a material and fixing that they know is going to be suitable,” explains Emma Learmonth, Aquasign director.

QR code materials for underwater use

With its unique anti-fouling technology, Aquasign material ensures these codes are easily detected and remain visible even in the harshest of conditions.

“One of the challenges we come up against is it can be very cheap, or effective, identifying equipment by just painting something or using materials like plastic or vinyl. These can be good solutions for short term applications. But if the applied codes need to be scanned regularly over an extended period of time subsea, the materials used need to be robust,” adds Learmonth.

“While codes printed onto plastic or vinyl are cheap to produce, they are more likely to deteriorate over time and need to be replaced. Whereas our silicone solution is designed specifically for long term subsea use and is completely non-toxic, environmentally approved for even the most stringent of environments. This solution will last the lifetime of your subsea asset, reducing the need to replace – which isn’t just the initial cost of the codes but the operational time subsea to change out.”

How to attach QR codes or target markers

Applying QR codes to new marine installations is fairly straightforward and can be performed on dry land using either adhesive or mechanical fixing options. However, for the ArUco markings, in particular, the tags must remain in the absolute same position to provide accurate readings. Robust fixings are therefore essential. Calibration of the ArUco tags typically happens onshore, but subsea checkerboards or scale bars can also be used.

Ideally, the code or target markings are applied to new hardware before going subsea. But there is also the need to survey and inspect equipment already on the seabed, particularly on ageing equipment or items identified for decommissioning.

Yet because some of these underwater assets may have been originally installed decades before the QR code was invented, retrofitting a tag in the murky depths is not without its challenges. Application is not as simple as printing off a code and sticking it on a component underwater. Aside from the adverse subsea environment and issues with visibility, these assets may be in remote locations that are difficult to access. In such instances, what is known as a retrofit or subsea fixing will be required.

Subsea magnets

Aquasign’s bespoke subsea fixing range allows both the markings and rare earth magnets to be encased within polycarbonate frames that can easily be installed by either diver or ROV. Handles or tethers can be incorporated to suit the specific project needs. These can be applied to flat or curved surfaces and provide a minimum holding force of 29kg (284 N).

Aquasign Ltd provides the full suite of capabilities to apply signage in subsea environments using eco-friendly materials. Based in Aberdeen, Scotland, the company’s anti-fouling signage products come with a 60-year guarantee. Furthermore, its solutions have been proven worldwide in the adverse operations of the oil & gas industry in the North Sea to the Gulf of Mexico. This experience makes Aquasign products easily transferable for energy installations in similar marine environments such as offshore wind farms and tidal turbines.

“Our products can provide stability because we’ve got a long track record of a product that can withstand the test of time in a subsea environment. And a lot of the time, these markings are used for critical positioning. So, they need to be able to identify them or make it as clear as possible for the cameras to read them,” adds Emma Learmonth.