Varnish is a common issue in circulating systems where oil is used to provide a continuous flow of lubricant to bearings, gears and other components of industrial equipment. Even the smallest amount of varnish can result in reduced system performance and/or equipment failures. Sludge or varnish adhering to servo or thermostatic valves can cause the valves to stick, bearings to overheat, and heat exchange performance to be impaired, often producing elevated oil temperatures. Solid particle contaminants that imbed into varnish can also lead to increased component wear in valves, gears and bearings.

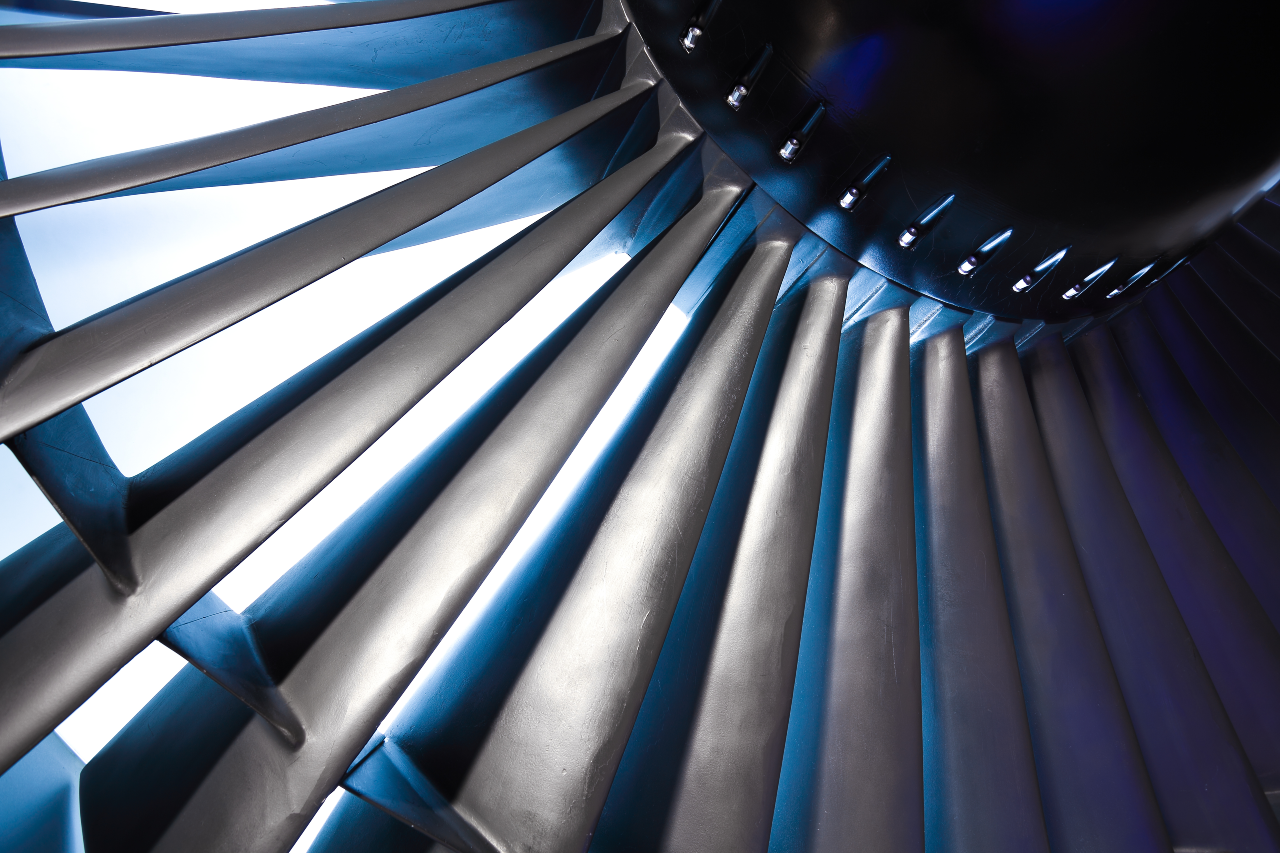

Varnish build-up in turbine systems can have a serious adverse effect on system performance, equipment longevity, operational flexibility, and lubricant life. Over the life of a piece of equipment, this can equate to huge financial losses.

As part of the VARTECH technology launch, Texaco experts have created A Guide to Varnish Testing Methods. This free to download guide focuses on how in-service oil testing can help identify the potential for varnish in turbine systems.