Whale field is a deep-water oil field located in the southern portion of the US Gulf of Mexico.

The field is operated by Shell with a 60% working interest and co-owned by Chevron, which holds the remaining 40%.

The Whale discovery is amongst the largest exploration discoveries made by Shell in the US Gulf of Mexico in the last decade. It adds to the company’s list of successful results from its exploration in the Paleogene formation in the Perdido area. Shell’s deep-water projects portfolio in the area includes Kaikias, Appomattox and Coulomb Phase 2.

The Whale field development will include a floating production unit (FPU) that will be operated in the Alaminos Canyon Block 772 in the deep-water Gulf of Mexico.

A final investment decision (FID) on the discovery is not expected until 2021 as Shell decided to cut spending plans amidst the plummeting oil demand and prices due to the spread of the novel coronavirus. The FID was originally planned to be made in 2020.

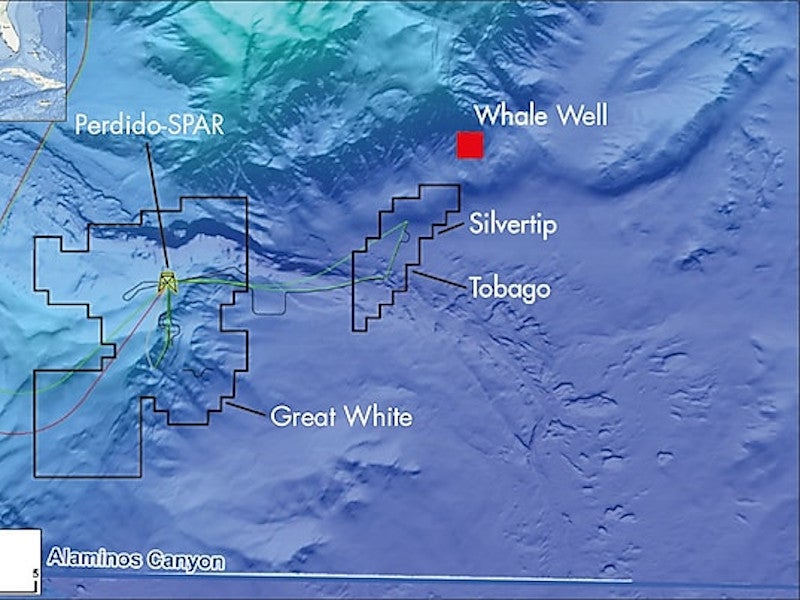

Location of Whale field

The Whale discovery is situated at a water depth of approximately 8,000ft, 322km south-west of Houston in Texas, US.

The field is located in the Alaminos Canyon Block 772 of the Perdido area in the Gulf of Mexico.

The Whale field is situated adjacent to the Silvertip oil and gas field, which is operated by Shell. Its location is 48.2km away from the Blacktip field and 16km from the Perdido floating oil platform.

Shell’s Perdido platform is located in Alaminos Canyon Block 857, at a distance of 402km south of Houston. It is the deepest spar and the second-deepest oil and gas production platform in the world.

Whale field discovery and appraisal details

The discovery was made using the Whale deep-water well in January 2018.

The discovery well hit net oil-bearing pay of more than 1,400ft and was evaluated through appraisal drilling for delineating the discovery and determining development options for the field.

The drilling of the appraisal and side-track wells was completed in March 2018.

Whale FPU technical details

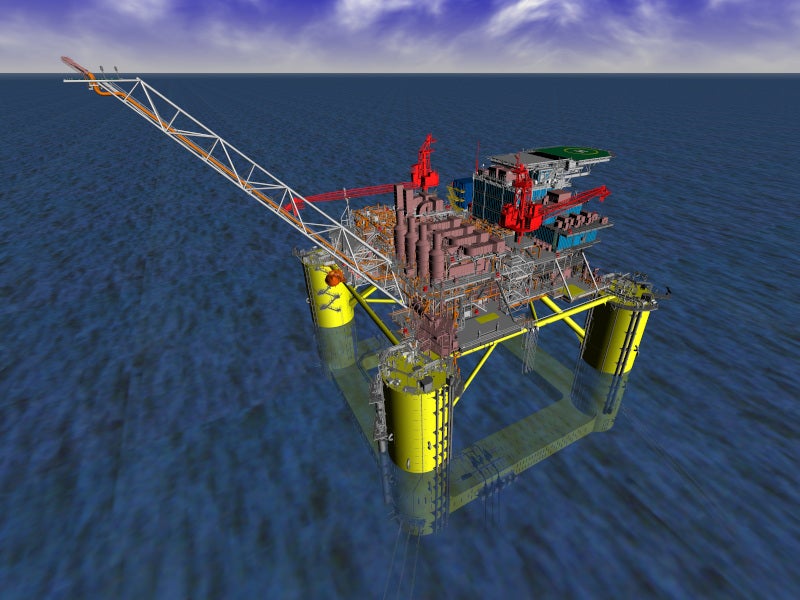

The Whale FPU will be a semi-submersible FPU integrated with a topside module and a semi-submersible floating hull having four columns. The module and the hull will have a total weight of 25,000t.

The FPU will incorporate a riser isolation valve (RIV) control system to facilitate shutdown of production fluids. The control systems can be installed using conventional I-Tubes or clamped onto existing risers.

The integration and commissioning of the FPU topside will be performed on ground level at the Tuas Boulevard Yard in Singapore, similar to Shell’s Vito FPU. The commissioning of the topside will be followed by raising and lifting using cranes to link it to a 51m hull.

The Whale FPU will be delivered as a single integrated structure.

Construction of the Whale FPU

The beginning of the construction phase of the unit was marked with a strike-steel ceremony held in February 2020.

The construction and integration of the floating production unit are expected to be completed in 2022.

Sembcorp’s cranes at the Tuas Boulevard Yard are capable of assembling the Whale FPU topside into a mega-block and integrating it with the hull in a single lift. The 30,000t lifting capability at the yard is the world’s heaviest for offshore construction.

The Whale FPU project will leverage significant synergies from the Vito FPU, which is under construction at the shipyard.

Contractors involved

Shell Offshore contracted Sembcorp Marine Rigs & Floaters to construct and integrate the topside and hull, in November 2019.

In February 2020, Deep Down was awarded a contract to provide the RIV control system and other subsea production equipment for the project.