The Western Isles fields are situated in the UK Continental Shelf (UKCS) in the North Sea. Dana Petroleum UK is the owner and operator of the project, which encompasses the Barra and Harris fields.

Dana Petroleum drafted a decommissioning programme for the Western Isles FPSO and associated field infrastructure in March 2023, with production cessation anticipated in the first half of 2024. The programme’s initiation is contingent upon environmental approval.

Location

The Harris and Barra fields of the Western Isles are located in UKCS Block 210/24a, 93km north-east of Shetland and 12km west of the Tern platform.

The water depth in the area ranges from 150m to 165m, with a reservoir depth of 6,000ft.

Western Isles details

The Western Isles has been in production since 2017 using a floating production, storage, and offloading (FPSO) facility for development. Oil is transported by shuttle tanker while surplus gas is piped to the Tern-North Cormorant gas pipeline.

Water injection maintains reservoir pressure while gas lift aids production. The reservoir’s nature necessitates clustering production and injection wells around two drill centres: North Drill Centre (NDC) and South Drill Centre (SDC).

The NDC and SDC leading towheads have integral eight-slot manifolds, which allows for a tie-back of up to 16 wells. Five production and three water injection slots are at the NDC while the SDC has four production and four water injection slots.

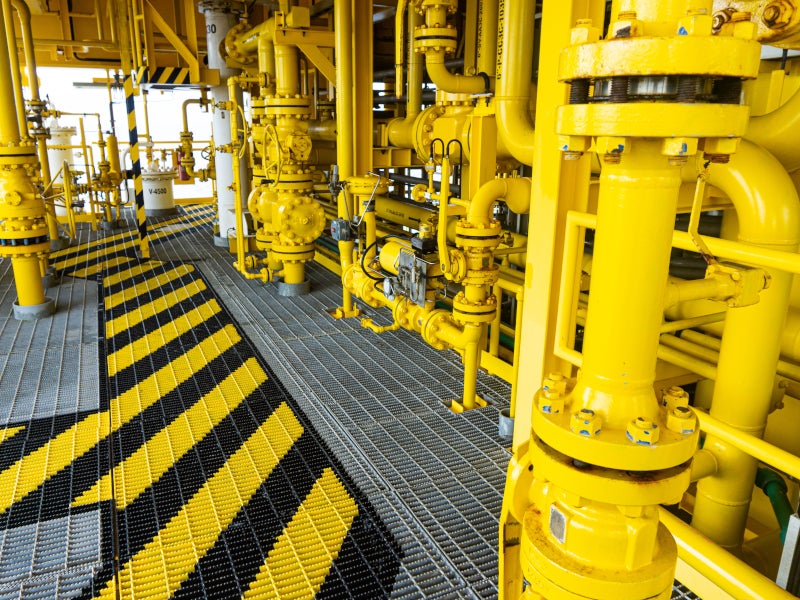

Gas importation was necessary to offset a reduced gas yield later during the field’s life. Subsea facilities are tied back to the FPSO via two subsea pipeline bundles and flexible risers.

Field decommissioning details

The decommissioning programme entails removing the Sevan 400 FPSO, flexible risers, dynamic umbilicals, and upper mooring line sections that include the top chain, buoyancy, and polyester line.

The lower H-shackle, excluding the bottom chain and anchors, will also be removed.

The subsea infrastructure decommissioning will involve removing subsea installations, pipelines, towheads, midwater arches, gravity bases, anchor chains, bottom piles, and wellhead protection structures.

Two towheads are present that are associated with each of the bundles (four in total) and seven wellhead protection structures.

The subsea pipelines include a single rigid pipeline, 20 spools, and six jumpers, with two bundles for NDC and SDC to be addressed in a future decommissioning programme (DP).

The subsea pipelines associated with well BP7, including pipelines, spools, jumpers and associated structures and stabilisation, will also be decommissioned.

Dana Petroleum and NEO Energy signed a sale and purchase agreement in November 2023, under which NEO Energy will acquire Dana’s Western Isles FPSO.

FPSO decommissioning details

The Sevan 400 FPSO is engineered and constructed by COSCO Shipyard Group in Qidong, China.

It has a storage capacity of 400,000 barrels of oil and a production capacity of 44,000 barrels of oil per day. The vessel features a 70m-diameter hull.

Sevan SSP was responsible for the front-end engineering design of the FPSO and provided ongoing support throughout the engineering, procurement, and construction management stages, as well as during marine operations and installation.

Before the FPSO’s mooring system is disconnected, all tanks containing hydrocarbons will be emptied, flushed, purged, and vented. Post-disconnection, the FPSO will be towed ashore for future reuse.

Mooring lines will be retrieved for either reuse or recycling, adhering to regulatory standards. The upper sections of the mooring lines, including the lower H-shackle, will be lowered to the seabed and recovered during the FPSO’s departure.

The lower chain sections linked to the anchor piles will be retrieved later in a separate DP.

Flexible risers and dynamic umbilicals will be detached subsea and at the FPSO, before being transported ashore for either reuse, recycling, or disposal.

The decommissioning will also include the removal of risers and umbilicals such as the gas import/export flexible riser, four production flexible risers, two water-injection flexible risers, two gas lift flexible risers, and two dynamic umbilicals.