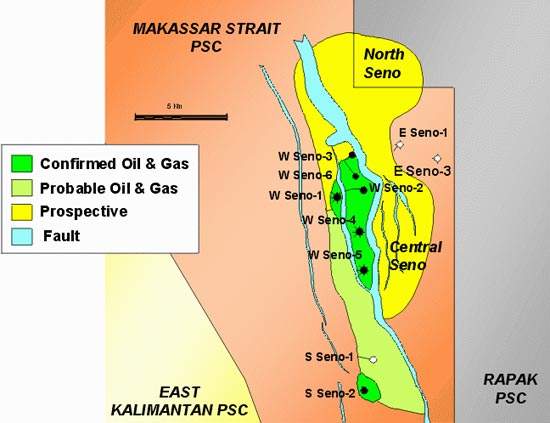

Lying in water depths of 2,400ft to 3,400ft, the West Seno field is Indonesia’s first deepwater development. It lies in the Makassar Strait PSC off Kalimantan, on the continental slope of the northern Mahakam Delta and 50km from the Attaka field. It is operated by Unocal.

The reservoir sands were deposited in the Miocene. The structure is a four-way dipping north-south oriented faulted anticline separated by faulting into two domains. The reservoirs have porosities of up to 30% and permeabilities of 10mD to 1,000mD.

Based on 3D seismic and nearby wells, the West Seno field was discovered in 1998 by the West Seno 2 well which encountered 205ft of pay. This was followed by West Seno 1, which encountered 270ft of oil and 103ft of gas. West Seno 5 (60ft oil and 141ft gas) was drilled to look at the southern extension while West Seno 3 (24ft oil and 39ft gas) looked at the Northern down-dip extension. West Seno 7 (163ft oil) was drilled 2km from West Seno 1. West Seno 8 (127ft oil and 97ft gas) was drilled in 1999.

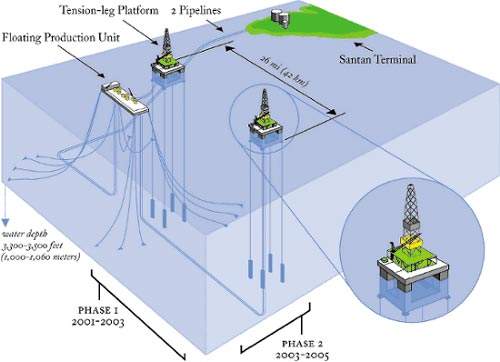

The field is being produced in a staged development by two tension leg platforms and a floating production unit, tied back by two export pipelines to onshore infrastructure.

TENSION LEG PLATFORMS

The first tension leg platform, TLP A, was installed in February 2003. Drilling plans call for 28 wells which will be completed by the end of 2004. The weight of the TLP deck and hull are 1,700t and 4,800t respectively, giving a total weight of 7,500t.

This TLP saw the first application of several design features including fixed, non-stroking tensioners for the production risers, a drilling production riser with mostly threaded and coupled connections and tender supported drilling operations.

The TLP tendons are 3,200ft in length and made up of 18 segments of 165ft each, with top and bottom segments used to attach it to the vessel and sea floor. The tendons have a diameter of 26in and a wall thickness of 1.036in. Drilling is carried out via Smedvig’s tender assist vessel West Alliance.

The second tension leg platform, TLP B, will be installed in 2005, three miles from TLP A, and will be the centre of a 20-well programme drilled by 2006. The TLP itself will have a capacity of 24 wells.

FLOATING PRODUCTION UNIT

The FPU, located 500m from TLP A, is a spread-moored barge lying in 3,200ft of water. It supports the production facilities and living quarters. It has a design capacity for 60,000b/d oil, 150 million ft³/d gas and 40,000b/d water. A maximum of 50,000ft³/d gas of the produced gas can be reinjected for reservoir support. Produced fluids arrive at the FSU via flexible flowlines. The FPU hull weighs 6,500t and the topsides 1,900t, giving a total weight of 8,400t.

PRODUCTION AND PIPELINES

Phase 1 production started in August 2003, achieving rates of 40,000b/d, which is expected to rise to 80,000b/d after Phase 2.The oil and gas streams are exported via 12in diameter pipelines to the Santan terminal approx. 40 miles away. The oil is measured in a custody transfer metering system and stored in existing tanks. The gas is metered and delivered into an existing pipeline for transport to the Bontang LNG facility.

The Allseas DP vessel Lorelay was selected as the deepwater lay vessel. It laid the lines out to approx. 1,060m of water at the FPU location. The pipeline from the shore to the end of the SCR (Steel Catenary Riser) totals 59.5km. These lines were laid individually. At the end of each line were 5ft of strakes and flex joints, with buckle arrestors installed every ten joints in water depths greater than 343m. Pipe welding was carried out using the phoenix welding machine.