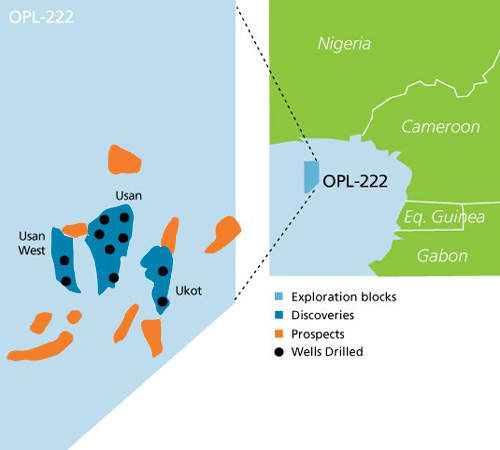

In February 2008, Total was given approval from the Nigerian Government to begin development of its offshore Usan field. Discovered in 2002, Usan lies in licence block OPL 222, approximately 100km south of Port Harcourt, in water depths ranging from 750m to 850m. The first production from the field was achieved in February 2012.

The field is operated by Total E&P Nigeria, a wholly-owned subsidiary of Total. It holds a working interest of 20% in the project. Partners include Chevron Petroleum Nigeria (30%), Esso Exploration and Production Nigeria (Offshore East) (30%) and Nexen Petroleum Nigeria (20%).

Proven and probable reserves of Usan were put at in excess of 500 million barrels of oil.

Usan discovery wells and appraisals

Usan-1 discovery well encountered significant net oil pay. It was production tested at a restricted rate of 5,000 barrels a day (bpd). The nearby Ukot field was discovered in 1998 and also encountered significant net oil pay, testing at a rate of 13,900bpd.

This was followed by Usan-2, which was located approximately two miles west of the discovery well and tested an up-dip portion of the fault block. Usan-3 was drilled approximately one-mile north-west of the discovery well and tested a separate fault block.

The Usan-3 well was production tested and produced 5,600bpd under restricted flow conditions. Ukot-2, an appraisal well on the separate Ukot discovery, was spudded in 2008.

Usan-4, located five kilometres south of the discovery, was drilled in 2003. It flowed at the rate of 4,400bpd from the first interval and 6,300bpd from the second interval. Usan-5 well was located six kilometres west of the discovery.

Usan-6 appraisal well was drilled around four kilometres south of Usan-5 in water depths of approximately 850m. During the well test, Usan-6 flowed at a rate of 5,800bpd under restricted flow conditions.

In 2005, Usan-7 and Usan-8 confirmed an eastern extension of the Usan field. Both wells were drilled using Transocean’s semisub MG Hulme.

Development of the Nigerian oil field

The development of the Usan field involves 23 production wells and 19 water and gas injection wells connected to a two-million-barrel capacity floating production, storage and offloading (FPSO) vessel by subsea lines and risers.

Usan FPSO details and contractors involved

Construction of the FPSO for the project was started by Hyundai Heavy Industries in 2008. The vessel was launched in November 2010 and arrived at the field in July 2011. The FPSO measures 320m in length, 61m in width and weighs 116,000t. The production capacity of the vessel is 180,000bpd.

Cameron was awarded a contract with a value of approximately $650m to provide subsea systems for the initial phase of the 44-well Usan subsea development.

According to the contract, which was awarded in March 2008, Cameron was required to provide subsea systems engineering and project management, along with subsea Xmas trees, production and intervention control systems, manifolds, flowline connection systems, installation support and associated spares for Total’s Nigerian subsidiary.

Cameron subcontracted Acergy to provide fabrication, assembly and testing of eight manifolds and associated structures.

Saipem was awarded the contract for the umbilicals, flowlines, risers and oil loading terminal activities in March 2008.

The $1.3bn contract included engineering, procurement, construction, installation and pre-commissioning facilities.

In addition, it required Saipem to assist in the commissioning and start-up of the subsea umbilicals (72km), flowlines (61km) and risers connecting the 42 subsea wells to the FPSO, along with the oil-loading terminal, consisting of an offloading buoy and two offloading lines and part of the FPSO anchoring system.

Fabrication was carried out locally in Nigeria, mainly in Saipem’s Rumuolumeni yard.

The offshore installation was carried out by the highly specialised vessels Saipem FDS and Saipem 3000, in water depths ranging from 730m to 850m.

Nexans manufactured and supplied power, control, instrumentation and telecommunications cables for the FPSO. In July 2012, Fugro GEOS delivered an environmental and marine monitoring system for the Usan production platform.

West Capella drilling rig at the West African oil field

West Capella drilling rig was built by Samsung Heavy Industries at Samsung’s South Korea shipyard. The rig can operate at 10,000ft underwater and has a maximum drilling capacity of 37,500ft. The rig was positioned at the field in April 2009.