Tortue West gas field is located at a water depth of 2,850m in the Greater Tortue Complex, between the C8 block off the shore of Mauritania and the Saint-Louis Profond block off the shore of Senegal. It is being developed under the Greater Tortue Ahmeyim development project.

The Greater Tortue Ahmeyim project is jointly owned by BP, Kosmos Energy, Petrosen and Société Mauritanienne Des Hydrocarbures et de Patrimoine Minier (SMPHM).

Kosmos Energy is serving as the exploration operator for the gas field, while BP is acting as the operator for field development.

The final investment decision for phase one of the project was taken in December 2018 and the first production is expected in 2022.

Location and reserves of the Greater Tortue complex

The Greater Tortue complex is a cross-border structure off the coast of Senegal and Mauritania. It is estimated to contain more than 25 trillion cubic feet of gas.

Exploration activities by Kosmos Energy identified three different trapping geometries, comprising Tortue West, Tortue East, and Tortue North.

Tortue West contains gas in the lower Cenomanian intervals, while Tortue East and Tortue North are estimated to hold reserves in the Albo Aptian targets.

Tortue East and Tortue North will be explored at a future date.

Tortue West discovery

The gas field was discovered by drilling of the Tortue-1 exploration well to a total depth of 5,250m in Mauritania’s offshore by the Atwood Achiever drillship in mid-2015.

The well struck approximately 117m (373ft) of net hydrocarbon pay in high-quality reserves in the Cenomanian and Albian intervals.

Exploration at Tortue West

The Guembeul-1 and Ahmeyim-2 wells were drilled to explore the potential of the Tortue West accumulation.

Guembeul-1 was drilled in 2016, approximately 5km south of Tortue-1 offshore Senegal, encountering 101m (331ft) of net reserves in two high-quality gas reservoirs of the lower Cenomanian and lower Albian sequences.

Ahmeyim-2 well was drilled to a total depth of 5,200m offshore Mauritania in the lower Cenomanian and Albian sequences.

The well penetrated the seismic-infrared gas-water contacts and discovered 78m (256ft) of net reserves in two reservoirs.

It also enabled the field limit to be defined and also extended the productive field area from 50km2 to 90km2.

Results from the three wells drilled on Tortue West showed reservoir continuity and static pressure communication, indicating that Tortue is a single large gas field.

Ahmeyim-1 exploration well was drilled to a total depth of 4,884m at a water depth of 2500m to encounter net gas pay of approximately 30m in high-quality Albian reservoir in July 2019. The discovery expanded the potential of the project beyond 10MTPA LNG.

Appraisal on Tortue West gas field

Kosmos Energy completed a drill stem test (DST) on the Tortue-1 well in August 2017.

The well flowed at an equipment-constrained rate of 60 million cubic feet a day (mmcf/d) during the main flow period, with minimal pressure drawdown.

The test results support well designs with production capacities of up to 200 million metric cubic feet a day (mmcf/d).

Results from the DST will be used to prepare the field development plan and provide key parameters required for the front end engineering and design (FEED).

Samples collected during the test also support liquefaction, as the gas was considered to contain negligible impurities and liquids.

The Ensco DS-12 rig will further drill Yakaar-2 appraisal well in Senegal, followed by Orca-1 exploration well in Mauritania.

Tortue West gas field development details

The development plan for Tortue West includes an ultra-deepwater subsea system, which will be tied to the mid-water floating, production, storage and offloading (FPSO) facility to convert the produced gas into liquefied natural gas (LNG). The project involves the drilling of 12 wells, of which four will be initially connected to the subsea system via production pipelines leading to FPSO.

DLV 2000, North Ocean 102 (NO 102), the upgraded Amazon vessel, will be used for the installation of the subsea system. A multi-joint (hex) J-Lay system, dual pipe loading cranes and additional power generation systems will be used for the ultra-deepwater project.

Other components of the subsea system connections include five large-bore deep-water horizontal X-mas trees (DHXTs), a dual-bore manifold with six slot, a pipeline end manifold, subsea distribution units (SDUs), three subsea isolation valves (SSIVs), diverless connections and subsea production control systems.

Phases two and three of the project will increase the gas delivery capacity of the field from the subsea system to the processing platforms.

FLNG development details

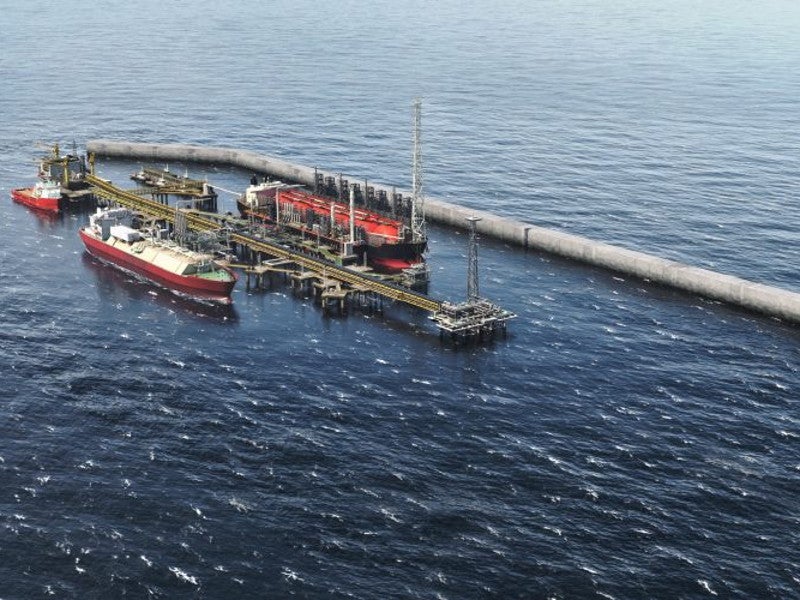

The processed LNG from the FPSO vessel will be transferred to a floating liquefied natural gas (FLNG) facility, located approximately 35km at a nearshore hub with pipeline connected to the domestic gas network. The FLNG facility will also be developed as a part of the field development.

An FLNG carrier, Gimi, owned by Golar LNG, is fitted with PRICO® liquefaction technology to convert it into an FLNG vessel for the project.

The hub facility will include breakwater-protected berths to accommodate the floating LNG facility for the exportation of LNG. The FLNG facility can provide approximately 2.5Mt of LNG a year.

Contractors involved

KBR was contracted to provide pre-front end engineering design (FEED) and support services for the Tortue gas field development.

CH2M was awarded the marine engineering and pre-FEED design contract for the hub facility.

The pre-FEED phase will optimise the location, layout, design and construction method of the hub facility.

Longdown EIC is the risk consultant for the project. Saipem was contracted for LNG hub and terminal facilities, while Eiffage Saipem Consortium received LNG hub and terminal marine infrastructure contract. BHGE will provide turbomachinery equipment for four FLNG compression trains for the project.

BHGE, in partnership with McDermott, received contracts to supply subsea umbilicals, risers and flowlines (SURF), and subsea production system (SPS) equipment for the project in March 2019. TechnipFMC won an engineering, procurement, construction, installation and commissioning (EPCIC) contract for the FPSO unit of the project.

Nexans was awarded engineering, procurement, manufacturing, testing and management contract for approximately 100km of subsea umbilicals and related accessories for the project in August 2019.

Black & Veatch’s patented technology PRICO® is used for the development of the FLNG vessel for the project. The company has collaborated with Keppel Shipyard for the conversion work of the carrier.

Other contractors involved in the project are Eiffage Génie Civil Marine, Bygging Uddemann, and Ampo Poyam Valves.