The Terra Nova field is located 350km east-south-east (ESE) of St John’s Newfoundland and 35km south-east of Hibernia.

It was originally discovered in 1984 by Petro-Canada. Field reserves have been estimated at 406 million barrels (Mbbl).

Environment

Terra Nova’s water depths are shallow, between 90m and 100m.

The mean annual wind speed is 35kmph, with the strongest recorded wind speed being 145kmph and the largest recorded wave height being 25m.

The area is characterised by the seasonal presence of floating sea ice ranging in thickness from 0.5m to 1.5m, which is produced by the freezing of the ocean’s surface layer and icebergs.

Reservoir

Terra Nova is subdivided into three major structural blocks: the Graben, the East Flank and the Far East.

The field is estimated to contain over one billion barrels of oil in place, including about 400Mbbl recoverable reserves.

The Far East block, which is not yet drilled, is expected to add at least 100Mbbl of reserves to the 300Mbbl that have already been estimated within the Graben and East Flank.

The estimated peak production rate is 125,000b/d from the Graben and East Flank portions alone.

A total of 32 wells are planned for the Graben and East Flank blocks, including 20 production wells, ten water-injection wells and two gas injection wells.

For the Far East, a total of 12 wells are planned, including six production wells and six injection wells. Field life is expected to be 18 years.

Development

Petro-Canada selected the Grand Banks Alliance (SBR Offshore, Doris Conpro, PCL Industrial Constructors, Coflexip Stena, Halliburton Canada and FMC Canada) to carry out engineering, procurement, construction, installation, commissioning and possibly pre-development drilling activities up to the production of first oil.

The project partners and Grand Banks Alliance consequently established a single alliance: the Terra Nova Alliance, with each company participating on a risk-and-reward basis.

Production

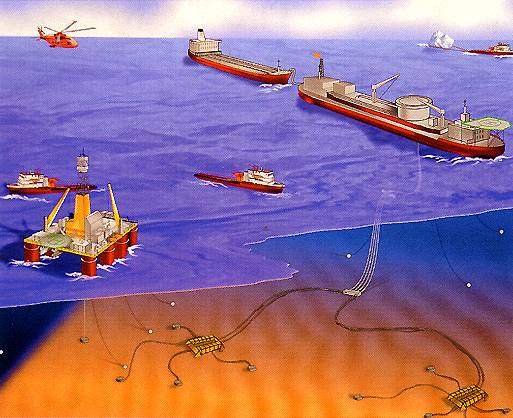

The subsea layout will consist of a production well feeding into a template, which in turn will be connected by flexible flowlines to a riser-base manifold (RBM).

In order to protect the subsea wells from iceberg scour, they will be set in glory holes, which are large holes drilled in the seabed that equipment can be installed within.

Flexible risers will connect the RBM to an FPSO. The vessel will have a length of 280m and a width of 45m.

The combination of low air and water temperatures with wind and wave action, makes superstructure icing a consideration during the winter months. This means that an allowance of several hundred tonnes of superstructure ice accumulation must be factored into weight and stability calculations.

There must also be procedures for monitoring and mechanisms for controlling ice build-up on the structure and substructures of the offshore facilities.

Low water temperatures require that fluids such as hydraulic control fluids be heated or treated to lower their freezing point. Similarly, low temperatures combined with the waxy nature of the crudes require that the flowlines and riser are insulated to reduce wax deposition.

The FPSO is designed to operate in moderate sea ice up to a limit of five-tenths coverage, and to disconnect, as required, to avoid heavy pack ice and potential collisions with icebergs.

The 9000t topsides facilities will be installed approximately 4.5m above the main deck. They will contain the necessary equipment to produce 150,000b/d oil, and inject 250,000bbl of seawater/day and 125MMcf/d of gas.

The FPSO hull will have an integrated storage capacity of 900,000bbl.

Export

The export system will be a tandem offloading system for the transfer of crude oil from the storage tanks of the FPSO to ice-strengthened shuttle tankers, ranging in weight from 80,000t to 120,000t.

The offloading system will be designed for connection to tankers in 5m significant-wave-height conditions.