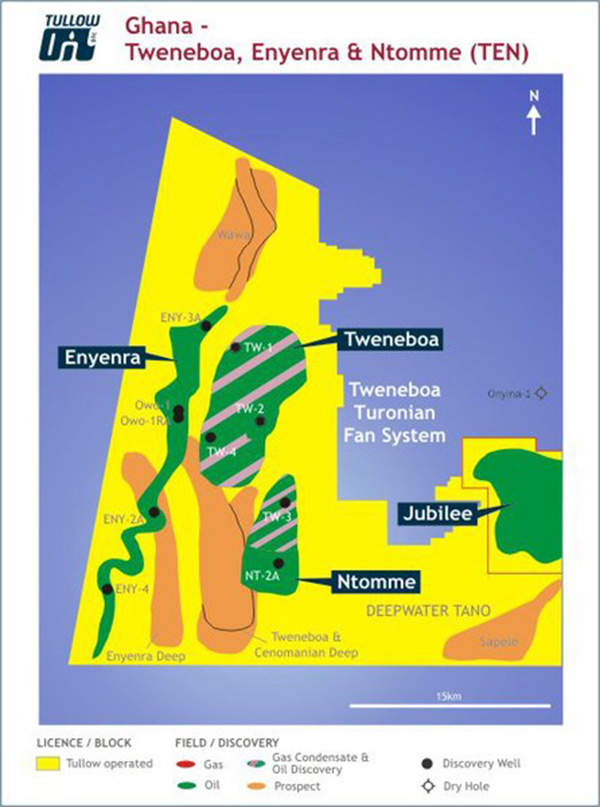

The TEN development project includes the collective development of three hydrocarbon accumulations, namely Tweneboa, Enyenra (formerly, Owo) and Ntomme. The three oil and gas fields are part of the Deepwater Tano license located offshore of Ghana.

The fields lie in water depths of 1,000m to 2,000m. The development is located 25km away from the Tullow-operated Jubilee field. It is the first deepwater field developed in offshore Ghana.

A field development plan for the project was approved in May 2013. First production from the project was achieved in August 2016. A peak production rate of 100,000 barrels of oil a day is expected by 2018. The project is expected to recover approximately 216 million barrels of oil.

Tullow Oil is the operator of the Deepwater Tano license and holds a 47.17% interest. Partners include Kosmos Energy (17%), Anadarko Petroleum (17%), Sabre (3.82%) and the Ghana National Petroleum Corporation (GNPC, 15%).

Discovery of Tweneboa and Enyenra fields

The Tweneboa field was discovered in March 2009 by the Tweneboa-1 well. The well struck 21m of net pay and four metres of oil-bearing sand.

Enyenra was discovered by the Owo-1 well in June 2010. The well struck 53m of light oil pay in two zones. Pressure data from the well indicated that the field belonged to the same accumulation as the Tweneboa field.

A sidetrack to the Owo-1 well was drilled in September 2010 by the Sedco 702 semisubmersible. The sidetrack encountered 16m of net oil pay.

Deepwater Millennium drill rig and Ntomme details

To confirm the potential of the Tweneboa field, a second well was drilled in 2009. The well, named Tweneboa-2, was drilled by the Eirik Raude semisubmersible and encountered 32m of net pay, including two hydrocarbon zones of oil and gas.

To establish the potential of the fields, Tullow commenced an accelerated appraisal programme in 2011. The programme began with the drilling of the Tweneboa-3 well by the Deepwater Millennium drillship in January 2011. The well discovered the Ntomme field, which was established as a different gas and condensate prospect.

Further appraisal activities at the Tweneboa field included the drilling of the Tweneboa-4 well. Drilled in April 2011, the well encountered 18m of net gas pay and confirmed a western extension of the Tweneboa field.

Enyenra-2A appraisal well was also drilled in 2011 and struck oil in excellent quality reservoir sands. The well confirmed that the Enyenra field was a major light oil field. Appraisal activities carried out in 2012 included the drilling of the Enyenra-3A, Enyenra-4A and Ntomme-2A wells.

Drilled by the Deepwater Millennium drill rig, the Enyenra-3A well defined the northern part of the Enyenra field. The Enyenra-4A defined the southern part of the field encountering 32m of net oil pay. Enyenra-4A was drilled by the Ocean Olympia drilling rig, to a depth of 4,174m.

The Ntomme-2A well was drilled to appraise the Ntomme field. The well struck significant oil pay located beneath the Ntomme accumulation.

Field development using an FPSO facility

Tullow jointly developed the three fields using a single floating, production, storage and offloading (FPSO) facility. A total of 33 wells were drilled, including 15 oil production, 15 water injection, one gas production and two gas injection wells. Another 16 wells are expected to be drilled in the future, depending upon the production levels.

Hydrocarbon fluids from the wells are collected at a subsea manifold tied back to the FPSO. The fluids are processed onboard the FPSO to separate crude oil and gas. Crude oil is offloaded onto tankers for export to markets. Gas is injected into the reservoirs or used for powering the FPSO. The gas may also be exported to the Jubilee field for future transport to shore.

The front-end engineering design (FEED) for the FPSO was selected through a design competition. Modec was preferred to deliver the FPSO for the project.

The FPSO was designed for a processing capacity of 105,000 barrels of oil a day. It is spread-moored and includes an oil offloading buoy.

The FEED for the subsea infrastructure was carried out by IntecSea.

Contractors involved

Technip received two contracts from Tullow Ghana for the TEN Project in October 2013. The scope of the contracts includes engineering, fabrication and installation of risers, flow-lines, spools, water injection and gas injection rigid flow-lines and well rigid jumpers, and delivery of pre-fabricated rigid jumpers.

Wood Group secured an engineering services contract to support Tullow Ghana and its partners throughout the development of TEN project in July 2014.

Jurong Shipyard received a contract from Modec Offshore to complete the repair and convert a VLCC into a FPSO vessel for the TEN project in October 2014.