The Tamar field is a natural gas discovery located within exploration permit 309 in Israel. It was discovered in January 2009 and is the company’s largest find to date.

The partners in the field comprise Isramco (28.7%), Chevron Mediterranean (25%), Tamar Petroleum (16.75%), Tamar Investment 1 RSC (11%), Tamar Investment 2 RSC (11%), Alon Natural Gas Exploration (4%) and Everest Infrastructure (3.5%).

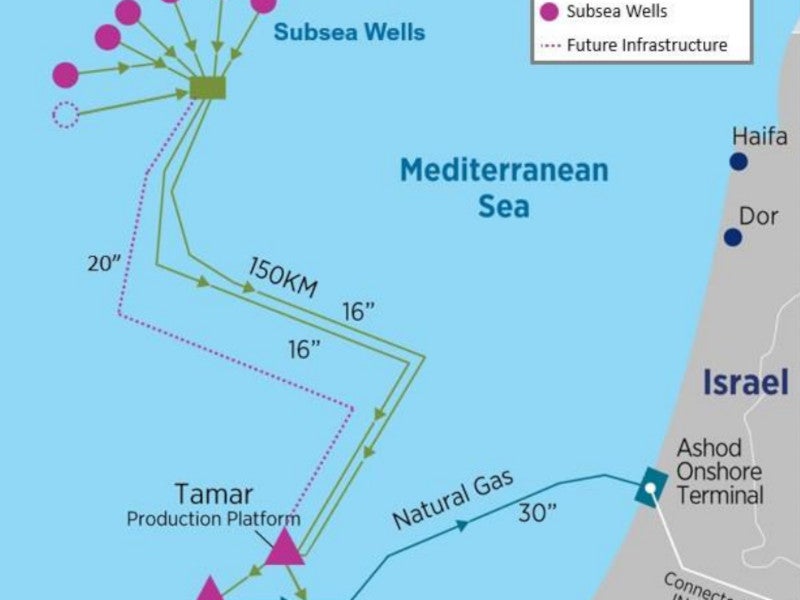

The field has six subsea wells, each with a production capacity of 250 million standard cubic feet per day (mmscfd).

The project was approved in August 2010. First production from Tamar was achieved in April 2013. The field reached full production capacity by the end of July 2013.

The field was initially operated by Noble Energy until it was acquired by Chevron in 2020. It is currently undergoing an expansion to increase natural gas production.

Tamar gas field location

The Tamar field is located in the Levantine basin of the Eastern Mediterranean Sea. The prospect falls under the Matan Block licence 309.

The Matan deepwater block covers 318km² while the Tamar structure is spread over 250km².

The first appraisal well that discovered Tamar’s natural gas reservoirs is 90km west of the port of Haifa on the Israeli coast.

Tamar discovery and appraisal

The presence of natural gas in the Tamar field was discovered in January 2009. The discovery was made by the first appraisal well Tamar-1.

A total of three reservoirs were found by the Tamar-1 appraisal well at a water depth of about 5,500ft.

Tamar-1 targeted sands lying at 2,500m subsea. The cost of drilling the appraisal well was initially estimated at $40m but escalated to more than $145m.

Tamar-1 discovered three high-potential gas reservoirs at the field. During flow testing in the month that followed, Tamar-1 yielded a flow rate of 30 million cubic feet of natural gas per day (mmcfd).

The drilling of Tamar-2 confirmed high-quality gas at the reservoirs and surged the total reserves at the field from 5 trillion cubic feet (tcf) to 6.3tcf of natural gas. In April 2011, the drilling of four more wells – Tamar-3, Tamar-4, Tamar-5 and Tamar-6 – began.

Tamar-5 did not encounter any gas, but Tamar-3 discovered a new layer of gas in the field. The new discovery, layer D, was found at a depth of 5,160m and was expected to contain between 0.5tcf and 1.5tcf of gas reserves.

Tamar field reserves

The Tamar prospect is estimated to contain 10.2tcf of gas and one million barrels (mmbbl) of condensate in 2P reserves, as of December 2023.

Atwood Hunter rig for Tamar gas field

The appraisal wells at Tamar were drilled by the Atwood Hunter rig, a semi-submersible rig owned by Atwood Oceanics. The rig can drill to a maximum water depth of 5,000ft.

Atwood Hunter was used to conduct drilling at Dalit, another Israeli field operated by Noble Energy.

Atwood Hunter was constructed in 1981 and refurbished in 1997. It was further upgraded in 2002 and can drill to depths of 28,000ft.

Tamar production

Gas is produced through five subsea wells, which are tied back to the Tamar platform. Two subsea gathering pipelines carry gas from the manifold to the platform.

The wells are connected to the platform via flowlines that stretch for 150km. The platform itself is situated at a depth of 800ft and has a processing capacity of 1.1 billion cubic feet (bcf) of natural gas per day. The topsides of the platform comprise four deck levels and have a mass of nearly 10,000 tonnes.

Each of the five subsea wells can flow 250 million cubic feet (mcf) of natural gas a day. In December 2009, Noble Energy entered into two agreements to supply the natural gas produced at Tamar, with the expectation of generating revenue of $10.5bn.

The first agreement was projected to produce a revenue of $1bn in exchange for the supply of 200bcf of gas. The Letter of Intent (LoI) also includes a provision to increase the supply to up to 700bcf.

The second LoI for the sale of Tamar natural gas was signed in December 2009 with the Israel Electric Corporation (IEC). Under this 15-year agreement, the IEC is permitted to purchase 95bcf of gas annually, which is estimated to generate revenue of $9.5bn for the stakeholders of the Tamar field.

A third pipeline is being installed as part of the Tamar gas field optimisation project aimed at reducing system bottlenecks while also increasing the field’s export capacity. The ongoing second phase of the project development will deploy in place compressors that are currently not in use.

Contractors involved

The contract for subsea umbilicals for the development of Tamar was awarded to Aker Solutions in April 2010. Aker supplied 240km of steel tube umbilicals. The contract also required Aker Solutions to provide subsea engineering and project management services for installing the umbilicals.

The umbilicals were supplied by Aker Subsea, a subsidiary of Aker Solutions.

Aker Solutions was awarded a separate contract in April 2010, for a complete mono-ethylene glycol (MEG) reclamation unit. The unit was employed to assist in removing the blockages in subsea pipelines installed at the Tamar field.

The MEG reclamation unit, which prevents ice formation and hydrates, thereby avoiding blockages in pipelines, was manufactured by Aker Process Systems, a subsidiary of Aker Solutions.

Aker Solutions received an additional order in June 2010 to supply subsea control equipment for the field.

In April 2011, EMAS was commissioned to install umbilicals and subsea equipment for the field, with the contract encompassing the supply of subsea suction piles and jumpers. The following month, Alliance Engineering secured a contract to design and engineer the Tamar platform and its topsides.

Corinth Pipeworks was awarded a contract in January 2023 to supply 155km of 20in longitudinally submerged arc-welded steel pipes for the Tamar gas field optimisation project.