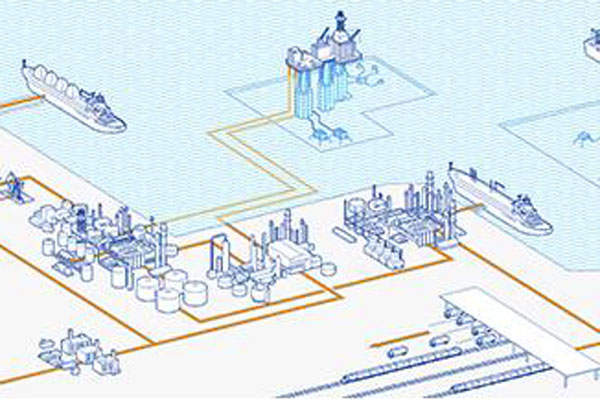

The South Tunisian Gas Project (STGP), or Nawara project, involves the installation of a central processing facility (CPF) at the Nawara well site for the pre-treatment of gas, a 370km pipeline, and a gas treatment plant (GTP) in the Ghannouch industrial district near the coastal city of Gabès.

Nawara field, which is located in the Ghademes basin in south Tunis, 50km south-west of Hammouda and Oued Zar oilfields, will supply gas for the project.

The production wells of the Nawara field are named Nawara-1, Ahlam-1, Ahlam-2, Sourour, Fella, Ritma, Khouloud, Benefsej-1, and Benefsej Sud-1.

The 50:50 joint venture (JV) of ETAP and OMV Tunisia will operate the South Tunisian Gas Project.

Nawara became a project of national interest when a Government Decree of National Interest was signed in June 2015.

The first production from the development was expected in 2016 but was ultimately delayed. The project was 80% completed as of July 2017.

Nawara field discovery and reserves

The Nawara field was discovered in June 2006 by the drilling of the Nawara-1 exploration well.

The onshore well was drilled to a total depth of 3,970m. It flowed at an initial rate of 5,970 barrels of oil a day and 58 million standard cubic feet a day (Mscfd) of gas.

Nawara field’s recoverable reserves are estimated to be 1.225 billion cubic metres (bcm) of oil and 10.225bcm of gas.

.Hasdrubal Gas Processing Plant, Tunisia

The new Hasdrubal onshore gas processing facility and the Liquefied Petroleum Gas (LPG) production facility will be located on the Tunisian coast between La Skhira and Sfax in Tunisia and is scheduled for completion in 2009.

Financing for the STGP

The overall investment for the project is estimated to be approximately €1bn ($1.27bn).

The development is primarily being financed by the European Investment bank (EIB), while the African Development Bank (AfDB) Group is also providing a $75m loan.

EIB has granted a loan of €150m ($208m) to ETAP and €230m ($320m approximately) to OMV as part of the initiative.

Details of the South Tunisian Gas Project

Each of the wells will be connected to the central processing facility via 6in in-field production flowline systems.

The CPF will have a treatment capacity of 2.7 million standard cubic metres a day (Mscmd) of gas and 7,000 barrels a day of condensate. It will be installed in an area covering 2.25ha.

An estimated 300 people will be required to install the facility, while ten personnel will be required to operate the facility once it comes online.

Gas from the field is expected to be transported through the new pipeline, while condensate will be transported through the existing Trapsa oil pipeline.

The buried gas pipeline was constructed of steel and features an inner diameter of 24in. It will cross the governorates of Tataouine, Kébili, Mednine and Gabes.

“The GTP will be installed on an area covering 35ha.”

The 370km-long gas pipeline will have a capacity of ten million standard cubic metres a day. Up to 300 personnel will be involved during the installation and five people will be required to maintain the pipeline when it becomes operational.

STGP’s new gas treatment plant will have an initial treatment capacity of 2.7 million standard cubic metres a day of gas to produce butane, propane, sales gas and condensate.

It is expected to start production in 2017 and will be expanded further in future to enable it to treat 7.3 standard cubic metres a day of gas.

The GTP will be installed on an area covering 35ha. Up to 500 personnel are expected to be involved during the construction of the facility and 50 people will be required to operate it.

The final products from the project will be supplied to SNDP and STEG. Sales gas, propane and butane will be supplied to these companies through export pipelines featuring diameters of 20in, 6in and 4in respectively.

Condensates will be stored in tanks before they are transported by trucks for sale.

Contractors involved with the STGP

Max Streicher–Bouchammoui Industries JV was awarded the engineering, procurement and construction (EPC) contract for the Nawara CPF and flowlines, while Enereco was awarded the EPC contract for the pipeline.

ABB was contracted to provide the gas treatment plant (GTP), including gas separation and liquefied petroleum gas (LPG) extraction units.

The company is also responsible for carrying out the electrification works for the plant. It is working in collaboration with Thermo Design Engineering under the $291m contract that was originally awarded in September 2014, with ABB’s share in the contract being $216m.

ABB subcontracted Safco Engineering to supply fire and gas systems and fire alarm control panels for the GTP, while C.S. Impianti was subcontracted to provide civil detail engineering.

Rina Consulting was subcontracted for the development of the health, safety and environment (HSE) solutions, as well as the project’s operation and maintenance activities.

EMC Group supplied the measuring and control instruments for the project. The organisation was also appointed by the Max Streicher–Bouchammoui Industries JV to provide engineering and supervision of civil works, piping, mechanical, quality and HSE of the project for the owners.

Enereco was contracted to provide the detailed design and support the procurement activities for the gas pipeline.

Borusan Mannesmann supplied 69mi (112km) of the 6in-diameter pipeline for the development.

Eurocontrolli was contracted to provide the engineering, design, procurement, site supervision and commissioning of the CCTV, access control and intrusion detection systems.