Schiehallion was discovered in 1993, with the semi-submersible drilling rig Ocean Alliance, whilst it was exploring the deep waters of the Shetland Trough in the NW Atlantic. Schiehallion lies in 400m of water and it extends across four blocks operated by BP, and a fifth operated by Amerada Hess. In all, six oil companies are involved in the licences.

Development

Total recoverable reserves are estimated at approximately 425 million barrels (bbl).

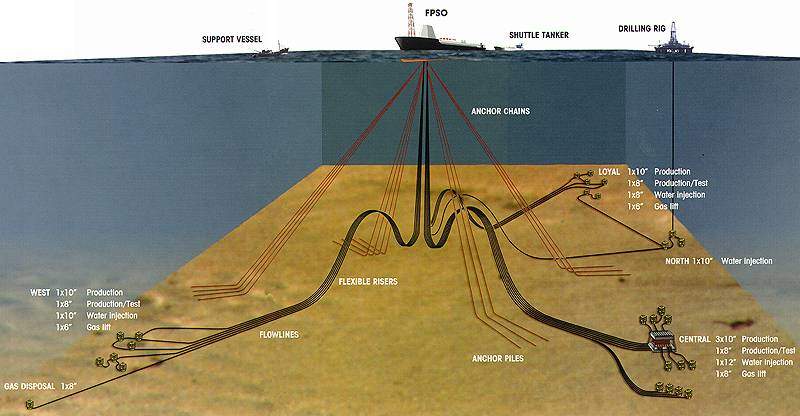

The estimated production life is 17 years, with a total output peaking at 142,000 barrels/day (117,000 barrels/day for Schiehallion and 25,000 barrels/day for Loyal). The field will be drained by 29 subsea wells in four producing clusters, with the oil flowing through subsea pipelines and risers into a newly built floating production, storage and offloading (FPSO) vessel. The Schiehallion FPSO is capable of storing 950,000bbl of oil.

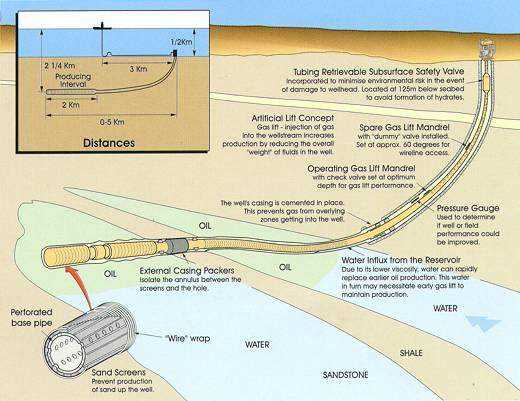

Well engineering

The thin, almost flat-lying reservoir formations are being drained by 16 horizontal production wells. The horizontal sections are up to 1,500m-long.

Twelve additional, non-horizontal wells inject water at other points in the reservoir, to sweep the hydrocarbons to the producing wells and maintain reservoir pressure. One further well disposes of gas and thus avoids flaring.

Subsea

The subsea layout comprises four main drilling centres, plus a separate location for a gas-disposal well. Three of the main drilling centres, Schiehallion Central, Schiehallion West and Loyal have both production and water injection wells. The fourth, Schiehallion North consists of just three water-injection wells.

At the largest drilling centre, Schiehallion Central, there are nine production wells and four water-injection wells. The production wells cluster around a subsea manifold, which receives the produced fluids from the wells. From there, flowlines take the fluids to the FPSO.

Schiehallion West consists of three production wells and three water-injection wells. Loyal consists of four production wells and two water-injection wells. For both Loyal and Schiehallion West, the function of the cluster manifold is performed by the flowline termination assemblies (FTA), rather than by a separate manifold structure.

The diverless connection system, DMaC, was used to connect the flowline jumper ‘tails’ and the flowline jumpers between the trees and the manifold/FTAs.

Risers and umbilicals

Reservoir fluids are transported from the seabed, through a turret in the vessel hull, up to the process plant, via 15 dynamic risers (13 steel / plastic encased pipes, ranging from a 5in-9.5in in diameter; and two umbilicals carrying electro / hydraulic cables for well control). The turret can accommodate up to 24 risers.

FPSO vessel

The FPSO vessel, designed and built at Harland and Wolff, is 246m-long, with a dead-weight of 154,000t. The simple, barge-type hull, built from pre-fabricated welded blocks, has a design life of 25 years and a fatigue life of 50 years. A high forecastle provides protection to the forward process area and the mooring turret. A full height centreline bulkhead allows seven pairs of cargo tanks in the mid-body, one pair forward of the mooring turret, providing a total of 950,000bbl of storage capacity.

Turret and moorings

The FPSO is moored by a top-mounted internal turret (TMIT), which allows the vessel to weathervane around its anchored position. Anchoring is achieved using 14 anchor legs, consisting of 6.25in studless chain and wire rope, fixed to anchor piles at a 1650m radius. The fixed part of the turret is composed of a 14m-diameter cylinder, inserted through the vessel hull and supported at deck-level on the turret collar, by a bogie-bearing system.

Production facilities

The production facilities consist of a number of processes for: the recovery of the reservoir products, the cleaning and re-injection of gas and water, and the chemical treatment of the reservoir and facilities. The two gas-oil-water separation trains are designed for a total peak 154,000bbl of oil per day.