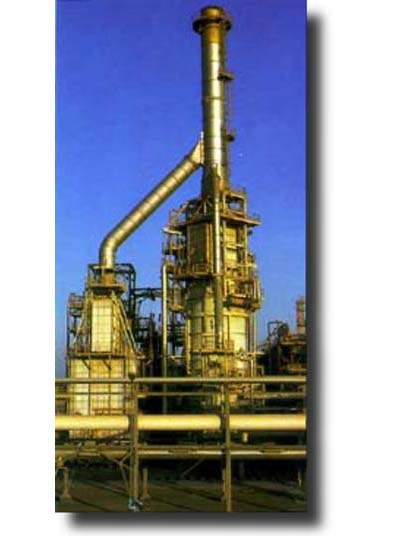

The Ruwais refinery is owned by ADNOC, though its subsidiary, the Abu Dhabi Refining Company (Takreer). The plant is located in the United Arab Emirates. It was originally commissioned in June 1981 and was officially inaugurated in March 1982. After further expansion in the mid 80s, the refinery was due for another upgrade in the second half of the 1990s. The `Ruwais Refinery Expansion Project’ covered the construction of two parallel trains for the distillation of condensate from Onshore Gas Development and Asab Gas Development Projects. The expansion of the refining facilities happened concurrently with the expansion of the petrochemical plant, also owned by ADNOC through a different subsidiary.

The present capacity of the refinery is 132,000 barrels/day, thanks to a $100 million upgrade in 1995. The total plant capacity after expansion will be 280,000 barrels/day of condensate processing with associated downstream facilities such as naphtha stabilization, kerosene sweetening, and offsite facilities, including an additional tank farm comprising 23 large tanks. The project began in the second half of 1997 and was completed by the end of 2000.

Snamprogretti

The lead contractor for this new expansion was Snamprogetti. This contract is thought to be worth $300 to $400 million. Snamprogetti provided detailed engineering, supply of materials and equipment, construction, commissioning and start-up, and the training of personnel for plant operations. The company was also involved in previous projects at the Ruwais plant complex.

Other Companies

There were a wide variety of other companies also involved in the project. The Front End Engineering Design (FEED) engineer for the changes to the Ruwais refinery was Fluor Daniel. Invensys, through its American subsidiary Foxboro, was given overall responsibility for the control systems in the plant. The system is based on the company’s I/A series technology but also includes safety systems. Inspection and testing of materials and components for Snamprogetti were subcontracted to Rina Industry and Germanischer Lloyd. ABB supplied specialised control valves from its Italian division. The ABB group was also awarded the turnkey contract for the power plant and desalination plant located next to the refinery from 1998 to 1999.

Gasco Fractionation Plant

The work at the refinery and the petrochemical plant also meant that there was a need to upgrade the existing fractionation plant. This is owned by Abu Dhabi Gas Industries Ltd. (GASCO). The upgraded plant is needed to process and treat additional feedstocks from ADNOC Habshan and Ruwais refinery new projects and to supply the ethane gas to the new Borouge petrochemical plant. Treatment of the gas effluents is also provided to meet UAE emission requirements.

The existing plant comprises two LNG fractionation trains, propane and butane liquefied storage, pentane storage and export facilities. The project work consisted mainly of the revamping of the two existing LNG fractionation trains and refrigeration systems, the mercaptan removal sections and a sulphur recovery unit. The lead contract was awarded to the French contractor, Technip. A small contract for fasteners was also awarded to the British based firm, Andrews Fasteners.

Future Plants

According to press reports Takreer is considering expanding its facilities yet further. The company may expand the plant to have a capacity of 500,000 barrels/day. If this is done, the company’s output of sulphur is likely to go up in proportion. Takreer is also evaluating feasibility studies for the construction of its hazardous-waste management centre, to find ways to reduce the amount of waste and develop recycling procedures and techniques. The new optimism over future investment is allowed by the recovery in oil prices. As this is expected to last, there is a real possibility of substantial further investment.