The Presidente Bernardes Refinery (Refinaria Presidente Bernardes) in Cubatao, State of Sao Paulo, Brazil, is one of the country's largest and is responsible for the production of a little over 12% of Brazil's fuel oils.

While the refinery has undergone numerous expansions and updates, it is still one of the country's mainstays in fuel production and the industrial area in which it is situated is the largest centre for refining crude oil and producing chemicals in Brazil (45% of fuel comes from here).

The last upgrade to the Presidente Bernardes refinery occurred in 1998 when a diesel hydrotreater unit was commissioned (so that the refinery could produce low-sulphur diesel oil – a major pollution bugbear in Brazil); this was built through a $270m investment (part of $1bn that Petrobras invested in low-sulphur technology across all of its facilities during the period 1998–2002).

The diesel treatment unit started commercial production in January 1999 and had a processing capacity of 5,000m³ a day. Petrobras, the Brazilian national oil company, is the owner and operator of the Presidente Bernardes refinery. Cubatao was known in the 1980s as one of the most polluted areas on earth, but much work has been done by its industries to improve conditions.

NEW CONSTRUCTION AND EXPANSION

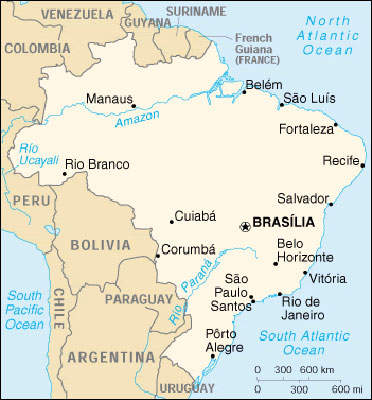

In 2007 it was reported that Skanska had been contracted by Petrobras to work on an expansion and upgrade of the Presidente Bernardes refinery (situated 60km from San Paulo).

The contract involves the construction of two new refinery units at the facility. These are a sulphur recuperation unit and a residual gas treatment unit. The investment into this technology totals $84m (Skanska share is 65%, $55m, SKr380m) and will aid the refinery in continuing to develop high-grade clean fuels and to lower its effect on the surrounding environment.

Skanska will be partnered in the project by the Brazilian engineering company Engevix Engeharia. Skanska is the senior partner and will be responsible for the management of the project. The project requires design, detailed engineering, procurement, supply, construction, assembly of components, commissioning / validation testing and start-up (a turnkey project).

The project began in the third quarter of 2007 and is expected to take 29 months with start-up scheduled for late 2009 / early 2010. The projects at the refinery are to improve the quality of emissions from the refinery and also to improve the environmental quality of diesel fuel produced.

BRAZILIAN FUEL

With reference to the environment and from an economic point of view Brazil has always been interested in the use of alcohol to substitute for conventional hydrocarbons in auto engines. The 'pro-alcohol' scheme for light automotive engines has been underway since 1975 and has been a success.

The next pollution problem for Brazil was to be the diesel engine. With this in mind and following major research the government decided to require that a proportion of ethanol (up to 15%) should be incorporated into diesel fuels (this is made difficult as emulsifiers are needed as well so the ethanol does not separate out in the fuel tank).

Buses in the regional town of Curitiba now run on a mixture of 86% diesel, 11% anhydrous alcohol and 2.6% AEP-102 additive (the additive prevents separation and also helps to increase the cetane number of the fuel so that its ignition characteristics are not compromised).

A possible alternative in the future would be to switch a proportion of ethanol production to give butanol, a much more compatible bio-diesel.

POLLUTION MONITORING

With Brazil taking atmospheric pollution much more seriously, the Presidente Bernardes refinery was one of the first to embrace an environmental pointer for atmosphere emissions; this was the AEISOX (Atmospheric Emissions Index of SOx).

Refineries are the main contributors of SOx emissions (the recently started Skanska project is part of the clean-up process). The refinery introduced the new AEISOX in an online plant information software interface that was accessible to the employees. In this way the SOx emission of different areas of the refinery may be monitored online.