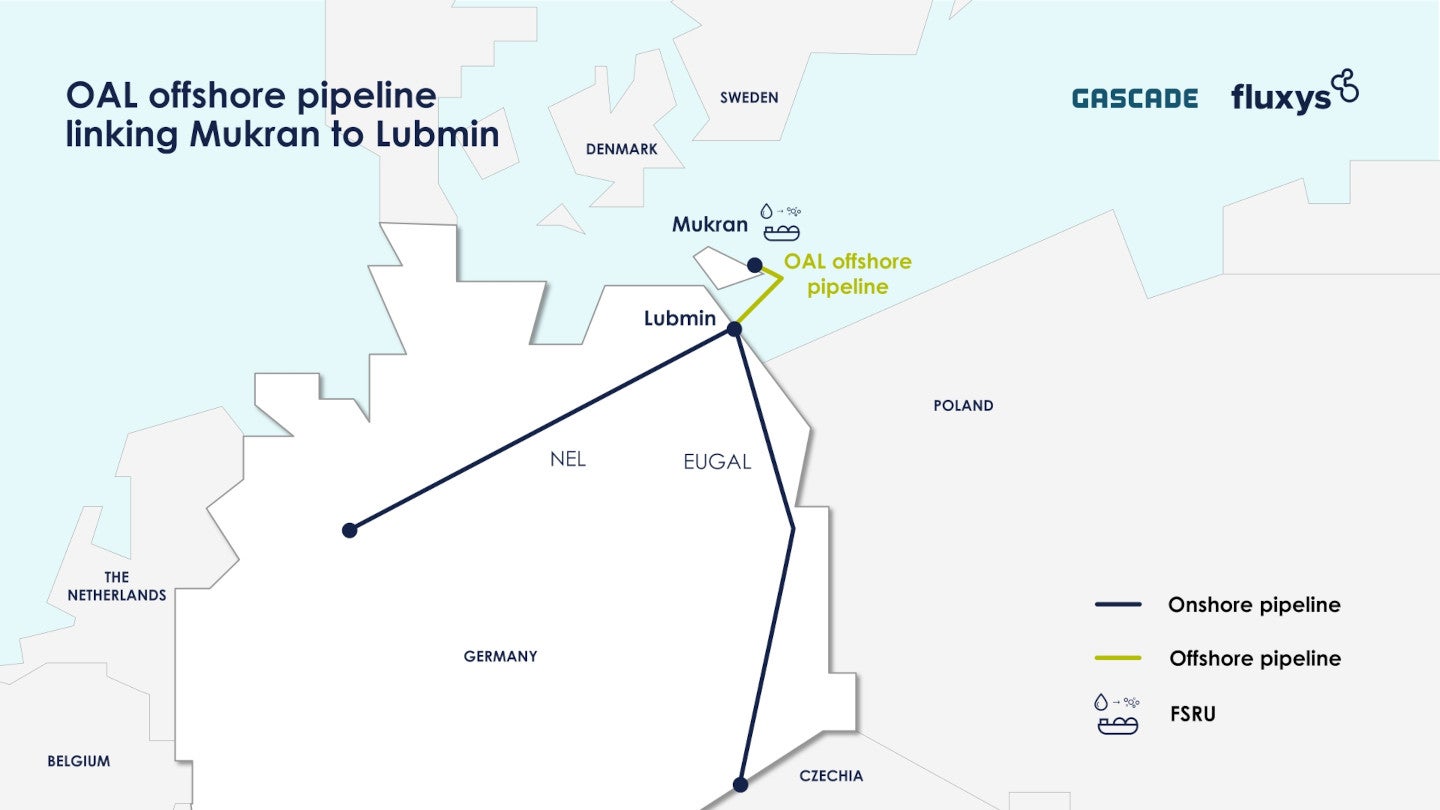

The Ostsee Anbindungsleitung (OAL) pipeline is a subsea gas pipeline built between Mukran and Lubmin, offshore Germany.

Spanning 50km in length, the pipeline is jointly owned by transmission operator Fluxys Deutschland (25%) and gas transmission system operator Gascade (75%).

The OAL pipeline consists of four sections: the Lubmin land section, the sea section from Lubmin to Kilometre Point 26 (KP 26), the sea section from KP 26 to Mukran, and the land section at Mukran.

The Lubmin land section received approval in February 2023, followed by the marine section from Lubmin to KP 26 in August 2023 and the land section at Mukran. The final approval, for the marine section from KP 26 to Mukran, was granted in October 2023.

Gascade completed the construction of the OAL pipeline in January 2024, and the first gas was fed into the pipeline in February 2024.

The OAL subsea pipeline strengthens Germany’s supply security by integrating regasified LNG [liquefied natural gas] into the gas networks of Germany and southeastern Europe.

The pipeline could play a pivotal role in achieving CO2 neutrality in the future by facilitating the injection of green hydrogen into Germany’s hydrogen core network via the Mukran entry point.

Ostsee Anbindungsleitung pipeline details

The 48in-diameter OAL pipeline is made of high-strength steel with a wall thickness of 26.8mm and a diameter of 1.2m.

The pipeline is encased in 90mm of concrete to ensure its stability and security on the seabed. It is buried throughout its entire route, with a cover depth ranging between 0.50m and 2.55m, contingent on local conditions.

The pipeline’s primary function is to connect the forthcoming LNG terminal at the Port of Mukran to the German pipeline network in Lubmin.

The Mukran LNG terminal features two floating storage and regasification units (FSRUs), to regasify LNG.

Deutsche ReGas is developing the LNG terminal, with plans to commence operations in 2024. Gascade, as the transmission system operator, is responsible for facilitating the terminal’s connection to the German gas transmission system.

Construction details

The pipeline’s installation involved three phases: pipe trench construction, welding and laying of the pipe string, and seabed restoration through backfilling.

The pipeline was placed within a pre-constructed trench and was buried along its entire length. Depending on the water depth and soil composition, dredging equipment including stilt pontoon dredgers, floating grab dredgers, hold suction dredgers and bucket chain dredgers were utilised.

Dredged materials were transported to an underwater storage site using hopper barges. A specialised laying barge was used to weld the pipes together into a continuous string.

The laying barge employed the S-lay method to weld individual pipes into a continuous string, forming a controlled S-curve to ensure welds of a quality comparable to those produced under factory conditions.

The final connection of the pipe strings, known as above-water tie-in (AWTI), was achieved using the barge’s lifting equipment to align them accurately. Two AWTIs were carried out during the construction of the pipeline.

The pipe trench was initially stabilised with a sand-gravel mixture after installing the offshore assembly line and then secured with an embedding material. Subsequently, the original trench material was backfilled as a second layer, and specifically sized stones were placed on the seabed to reconstruct the reefs.

The vessels Swarog and Biber were deployed to conduct surveying work along the offshore route, along with SkjoldR carrying out additional investigations. Archaeological investigations were carried out by the vessels HT01 Claus, Alberte HoJ and M/s Braune under the supervision of the State Office for Culture and Monument Preservation. The Castoro 10 pipelay barge owned by Saipem was deployed for the construction of landfalls.

Contractors involved

ABL, an independent energy and marine consultant, was commissioned by Gascade to conduct marine warranty survey (MWS) services to oversee the transportation and installation operations of the subsea pipeline. ABL’s team in Hamburg, Germany, coordinated the project’s daily management.

Italian oilfield services company Saipem was awarded the contract for the pipelaying works for the project in August 2023. The company’s scope of work included transportation and installation of the pipeline from the Lubmin site to the port of Mukran.

Construction company STRABAG was engaged to construct a 352m-long shore crossing microtunnel in Lubmin, completed in November 2023.