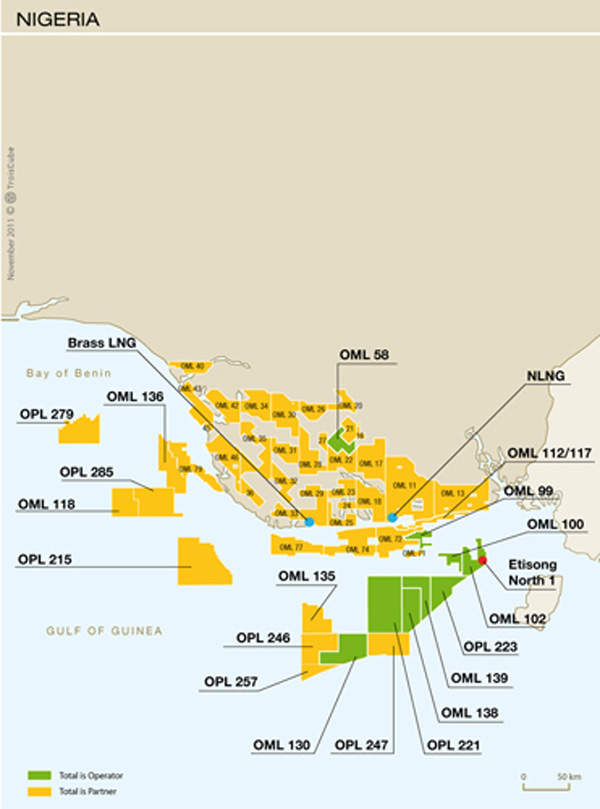

Ofon Field is an oil and natural gas field located in the Oil Mining Lease (OML) 102, about 65km offshore in the south-eastern coast of Nigeria. The reserves lie at a water depth of 40m (131ft). The OML 102 is owned by state-owned Nigerian National Petroleum Corporation (NNPC, 60%) and is operated by Total Exploration-Production Nigeria (TEPNG – 40%), formerly Elf Petroleum Nigeria.

The proved and probable reserves at Ofon are about 350 million barrels of oil equivalent. Phase one of Ofon Field started production in December 1997.

Phase two of the offshore Ofon Field development began in February 2012 and production commenced in January 2015. Phase two taps the undeveloped reserves at the Ofon Field. The development mostly focuses on producing natural gas. The recovered gas from the field is being compressed and transferred to the shore.

The second phase is intended to increase the production from the field from 30,000 barrels of oil equivalent per day (boepd) to 90,000boepd. The project involved the installation of four new platforms that include two production platforms, one accommodation platform for 124 people and a processing platform.

Ofon Field phases one and two oil and gas field development

The first phase of Ofon Field was launched in 1995. The reserves at the field were discovered using structural to stratigraphic exploration techniques. It consists of three platforms. The four-level production deck for Ofon phase one was constructed by McDermott. The 115ft x 102ft deck was built using deck/pancake technique. Total identified potential extension of the Ofon field in the southern flank in 2005.

Plans for the phase two extension were initiated in July 2007. The project was expected to come on stream in 2011. It has been, however, delayed for about five years. Upgrades to the three existing platforms and the design of the new platforms were undertaken by Aibel.

The Ofon phase two is a sustainable development and meets the standards set by the Federal Government of Nigeria. It boosts the regional economy and utilise local resources and manpower. The development works towards reducing greenhouse gas emissions and flaring of associated gas. It complies with environmental stewardship commitments undertaken by Total and EPNL.

Gas from the field is monetised using Nigeria LNG (NLNG) plant. The water produced during gas recovery is re-injected into the reservoir to boost the output.

Modification of phase one offshore facilities at Ofon

In October 2011, Ponticelli Nigeria (a subsidiary of Ponticelli Freres Group) was awarded a contract for modification and adaptation works on the existing Ofon phase one offshore facilities. The scope of works included the installation of 300t of piping and equipment, 200t of steel works, 40km of electrical wiring, telecom and instrumentation works.

Construction and installation contracts for Ofon Field phase two

TEPNG awarded a turnkey contract to Technip for supplying topsides of the Ofon 2 fixed platform (OFP2) in May 2007. The scope of works included loadout and transportation of the 16,000t topsides from South Korea to the field, engineering, supply and installation of the equipment through Unideck floatover method.

Nigerian engineering and construction firm in Nigerdock started construction of the Ofon 2 platforms in March 2012.

In October 2011, Saipem was awarded the contract to provide EPC, fabrication and installation of the OFP2 jacket and living quarter platform for phase two. Fabrication of the 900m-long, 1,970t jacket and 4,500t piles took place in Rumuolumeni Yard in Port Harcourt, Nigeria. The Saipem 3000 vessel was deployed to provide offshore activities at the field.

The $424m EPC and commissioning contract for the phase two was awarded to Eiffage Construction Métallique, in November 2011. Aveon Offshore was awarded a $50m contract to fabricate OFQ jacket, helideck, utility deck and piles for the LQ platform, in December 2011. The subsea systems were installed in March 2013.

Sofresid and OOPE are the engineering consultants. Akmos Global Services is the spare parts supplier for platform maintenance.

A consortium of Actemium Oil & Gas Engineering (AOGE) and Yokogawa was selected for providing the detailed engineering; functional analysis; HIPS detail studies; instrument data base management; supply of machines vibration monitoring system and electrical network power shading 5,000 I/O.

Nexans provided halogen-free, thermoset compound SHF2 or XLPE low smoke PVC outer sheath to reduce gas flaring.

JDR Cable Systems received a contract to supply subsea cables for the project, in February 2013.