Canada is well known for its reserves of oil sands and bitumen. Rough estimates of the extent of the Canadian deposits are that there are around 1.75 trillion barrels. As the world price of crude oil fluctuates but still heads in an upward direction

the economics of recovering this heavy oil and upgrading it to synthetic lighter crudes are becoming more and more attractive.

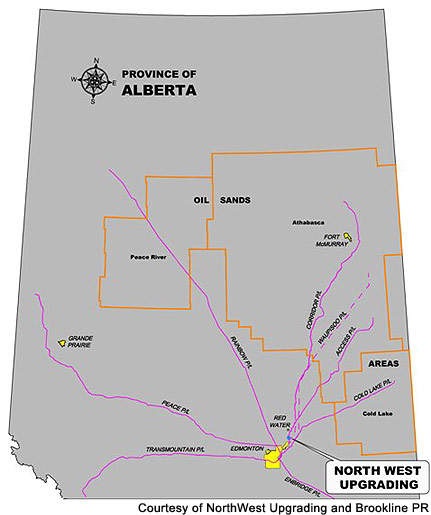

The Calgary-based company North West Upgrading, which is privately-owned, is making an investment in the oil recovery infrastructure in Canada by building an independent, heavy oil upgrader in Sturgeon County in Alberta’s industrial area.

The site is actually around 45km north-east of Edmonton and 5km north of Shell Canada’s Scotford operation, across the North Saskatchewan River.

NORTH WEST UPGRADER PROJECT

The new upgrader will increase the capacity of Alberta’s bitumen and heavy oil processing capability and will produce light, low-sulphur products and also diluent. The upgrader’s total processing capacity will be 231,240bpd of SYNBIT / DILBIT mix

bitumen feedstock (each phase will be able to process 77,080bpd).

The project will be constructed in three phases. Regulatory approval in the form of a decision report for the new facility was granted in August 2007 by the Alberta Energy and Utilities Board (EUB).

The capital cost estimate for phase one using figures from September 2007 is C$4.2bn. Site preparation for phase one was started in the fourth quarter of 2007. The start-up of phase one is scheduled for 2011 and phases two and three will follow by

2015.

CONTRACTORS AND CONSTRUCTION

At the start of the project North West formed a strategic alliance with SNC Lavalin and PCL Industrial Management for overall project management services and also for prime contractor site activities. These companies will perform around 50% of the

engineering, procurement and supply for the project.

In February 2007 the IJK Consortium was awarded a contract to fabricate the high-temperature and high-pressure vessels in the hydroprocessing and hydrocracking units of the new upgrader. The IJK Consortium is a partnership of three leading heavy

engineering companies including: Japan Steel Works Ltd, Kobe Steel Ltd and IPS Services Inc. The heavy wall reactors are expected to be completed by early 2009 (these have the longest lead time).

Voice Construction of Canada was awarded a contract in October 2007 for the initial earthwork and site preparation for the project. Other companies are involved in the project including Jacobs for the sulphur recovery unit and Chevron Lummus Global

for the residue hydrocracking unit.

LURGI CONTRACT

Lurgi AG of Frankfurt Germany was awarded an EPC contract for the construction of gasifier silo in November 2007. The project is worth C$500m and will involve the design, procurement and construction of a new 120mmscfd gasification-based hydrogen

plant, which will use Lurgi process technology including their Multi Purpose Gasification (MPG®) and Rectisol® gas-sweetening processes.

The high-purity hydrogen produced will be used to manufacture low-sulphur diesel. KBR have been awarded a sub-contract for the gasifier unit. The KBR contract is worth C$225m and is for the construction (pipe fabrication, module fabrication and field

execution) of the gasification unit.

The gasifier project will include the construction of around 100 modules and will take 30 months to complete (project starting in summer 2008). It is expected to be completed by 2011.

Rob Pearce, president of North West Upgrading, commented: “Gasification of bitumen bottoms to make hydrogen is the way of the future in upgrading and refining in Alberta; Lurgi brings a strong history of worldwide gasification and gas processing

experience to North West. We’re confident in their capacity and capability to ensure that this project remains on track and on schedule.”

PRODUCTION

North West Upgrading will take feedstock from independent bitumen producers in the area and then produce value-added products. Products will include: ultra-low-sulphur diesel, diluent for blending with heavy oil and bitumen, low-sulphur vacuum gas oil

(can be turned into gasoline) and butane for use as a fuel gas and also as a feedstock for petrochemicals.

Processing will involve conventional upgrading processes using atmospheric and vacuum distillation towers to process the blended bitumen. Light ends will then be passed on to the customers and the heavier and bottom material hydrocracked and

hydrotreated to produce the valuable products. The remaining residue for hydrocracking can then be gasified to produce hydrogen for use in hydrotreating or possibly as a fuel in its own right.