The North Field South (NFS) project is part of the larger North Field Expansion project, which is being developed by Qatar Energy in partnership with TotalEnergies, Shell, ConocoPhillips, ExxonMobil, Eni, Sinopec and China National Petroleum.

The North Field Expansion project is divided into two phases, with phase one involving the development of the North Field East (NFE), while phase two will see to the development of the NFS. The expansion will ramp up Qatar’s liquefaction capacity from 77 million tonnes per annum (Mtpa) to 126Mtpa.

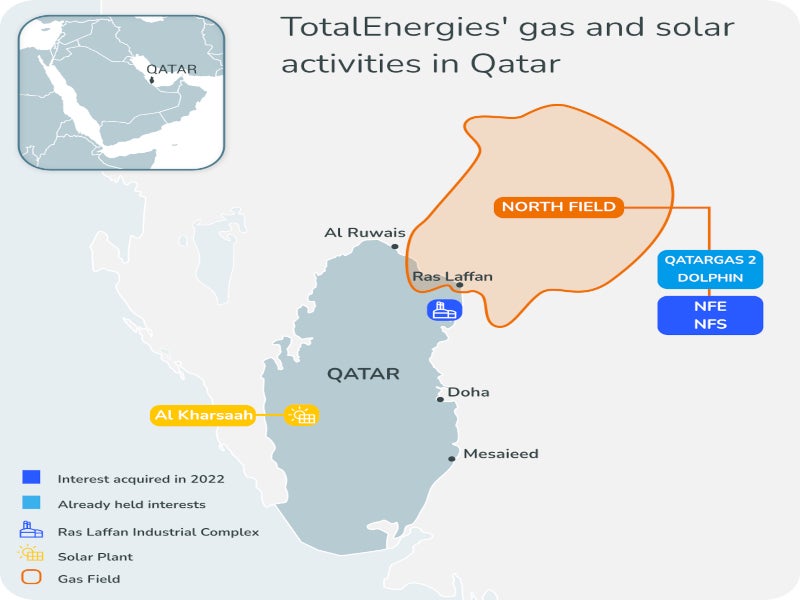

Qatar Energy holds 75% participating interest in the NFS project, while the remaining 25% is shared between international partners, which include TotalEnergies (9.37%), ConocoPhillips (6.25%) and Shell (9.37%).

Expected to begin production by 2026, the project will have a capacity of 16Mtpa. It will also help to reduce greenhouse gas (GHG) emissions and achieve Qatar’s climate ambitions.

North Field location and details

The North Field is located off the northeast shore of the Qatar peninsula and is the largest single non-associated gas reservoir in the world.

The North Field was discovered in 1971 and is estimated to contain over 900 trillion cubic feet of recoverable natural gas. The field covers an area of more than 6,000km2.

The first commercial exploration in the field commenced in 1991 with the commissioning of the North Field Alpha (NFA) complex. Production at the complex is carried out using 15 production wells and two wellhead platforms, namely WHP-1 and WHP-2.

Other facilities currently producing gas and condensate from the North Field include the North Field Bravo (NFB) and RasGas Alfa (RGA) complexes which were commissioned in 1996 and 1999 respectively. NFB produces 1.6 billion standard cubic feet per day (bscfd) of gas from 26 wells, while RGA produces 1.2bscfd from 15 wells.

North Field South project details

The NFS project will include five production platforms, 50 wells and gas pipelines to an onshore processing complex.

The onshore components of the project will include two liquefaction trains with a capacity of 8Mtpa each. It will also include a large 1.5Mtpa carbon capture and sequestration facility to reduce greenhouse gas emissions by more than 25%. The two LNG process trains will be equipped with AP-X liquefaction technology, which will provide higher LNG production with a flexible operation over a wide range of production capacities.

The equipment for the LNG trains will include main cryogenic heat exchangers (MCHEs), subcooling heat exchangers (SCHEs), Rotoflow® turbomachinery companders and nitrogen economiser cold boxes.

Two main refrigerant compressors (MRCs) will also be installed with each MRC train comprising three Frame 9E DLN Ultra Low NOx gas turbines including six centrifugal compressors across the two LNG trains.

Other components of the project include an LNG loading berth, LNG rundown lines and boil–off gas (BOG) recovery systems. Utility pipelines linking the southern part of Ras Laffan Industrial City to new storage tanks and export facilities in the city will also be installed.

Offtake agreement

Qatar Energy and ConocoPhillips signed two long-term LNG sale and purchase agreements (SPAs) for the delivery of LNG to Germany from the North field expansion project in November 2022. The first delivery is expected in 2026 to the LNG Terminal at Brunsbüttel, Germany.

QatarEnergy and Shell will supply up to 3.5Mtpa of LNG to the Netherlands as part of two long-term SPAs over a period of 27 years.

QatarEnergy and TotalEnergies also signed two SPAs in October 2023 for the supply of LNG to France for a period of 27 years. Expected to start in 2026, up to 3.5Mtpa of LNG will be delivered ex-ship to the Fos Cavaou LNG receiving terminal in southern France.

Contractors involved

Baker Hughes was awarded the contract to supply the two MRCs for the NFS project.

Engineering and construction solutions provider McDermott was awarded the front-end engineering design (FEED) contract for the project in August 2022. The scope of the contract includes FEED studies for offshore and onshore pipelines, cables and associated facilities. The company was also previously awarded a contract for the NFS Jackets, topsides and pipelines for the project.

Industrial gas supplier Air Products is supplying its AP-X® LNG Process technology and equipment for the project.

The engineering, procurement, construction and commissioning (EPCC) contract for the onshore facilities of the project was awarded to a joint venture (JV) led by Technip Energies in partnership with Consolidated Contractors. The JV will deliver the two LNG trains and the carbon capture and sequestration facility.

Engineering company Técnicas Reunidas was awarded an additional EPCC contract worth $560m in August 2023. The scope of the contract includes pipelines, interconnections, ancillary systems and other supporting components for the LNG off-plot facilities.