Petrobras is presently carrying out a project to develop the gas reserves of the Mexilhão field in the Santos Basin in Brazil. The field lies off the coast of Sao Paulo, approximately 160km offshore and in water depths of between 320m and 550m. The total cost of the development is around $1.9bn.

The Mexilhão project is of strategic importance, creating an infrastructure which will serve other gas fields already discovered in the region.

Discovered in 2003, it is one of the largest discovered to date by Petrobras in Brazil. Production is scheduled to begin in 2010.

Mexilhão drilling

The Mexilhão field is particularly challenging due to the high temperatures (+130°C at the well heads) and working pressures (10,000psi) involved.

Development drilling in the field began in 2005. Due to hard sandstone formations, however, initial drilling activities were adversely affected by high downhole vibration.

Development will be based on the fixed gas production platform PMXL-1, with the produced gas being conveyed through submarine pipelines to the shore gas processing plant and forward to the national pipeline grid. The development will see an initial production of 12 million cubic metres a day from Mexilhão and adjacent areas, with output reaching 15mcm per day.

Subsea contracts

FMC Technologies will supply the subsea gas production system. The $122m contract, awarded in 2006, includes six subsea trees and two subsea manifolds with multiplexed controls and related subsea systems. One of the landmarks in this contract is that the subsea system to be installed will be the first high-pressure, high-temperature subsea system in Brazil. Deliveries are slated for 2010.

Nexans won the $44m contract to supply the umbilicals in October 2007. Two different umbilical designs were developed to connect the individual wellheads to the subsea manifold and the manifold to the fixed platform.

The umbilicals will be used to provide electronic control of systems on the seabed, and hydraulic and chemical liquid injection.

Two umbilicals each around 22km in length, will run from the platform, at a depth of 170m, to the manifold at 500m, which carries out the control / distribution function on the seabed. A further seven umbilicals, totalling nearly 15km, will then run from the manifold to the seven well heads.

Mexilhão platform

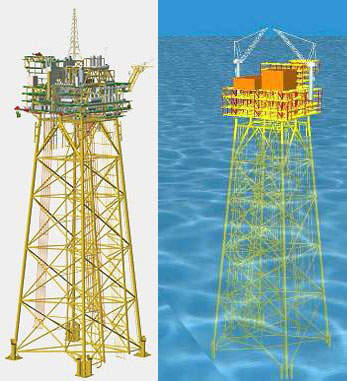

The Mexilhão 1 platform, which will be installed in a water depth of 172m, will be the largest offshore metallic structure ever erected in Brazilian waters. The platform will stand 230m tall.

The structure comprises a 12 000t topside, which will include a natural gas production plant designed with a capacity of 15 million cubic metres a day. Facilities will also be able to process 3,200m³ of condensate daily.

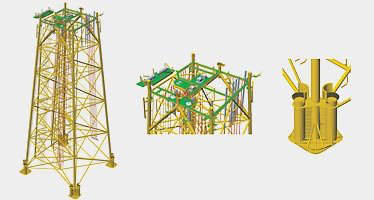

The topsides will sit on a 180m-tall tubular structure jacket which will weigh approximately 10,500t. This is secured to the seabed using 3,150t tubular steel piles up to 120m long.

The jacket and piles are being fabricated by Maua Jurong under the Petrobras-furnished design. The topsides deck and process plant will be purpose-designed by Maua Jurong in conformance with the front-end engineering design (FEED) provided by Petrobras.

In July 2009, Petrobras closed a $70m contract with Saipem for the installation of the PMXL-1 platform. Included in the contract is the transportation of the jacket, stakes and modules.

The installation of PMXL-1 is scheduled to take place in December 2009.

Acergy was awarded the Mexilhão gas export trunkline contract. Valued at approximately $400m, it covers the installation of 120km of 34-in diameter pipeline from the fixed platform to shore.

The pipelay programme was to commence in the first quarter of 2008 when the Acergy Piper was planned to be used. However, Acergy later classified the Mexilhão Trunkline Project as a discontinued operation because Acergy Piper, which was the sole asset of the project, was sold on 30 November 2008.

A natural gas processing unit, Monteiro Lobato Gas Treatment Unit (UTGCA) is under construction in Caraguatatuba in northern Sao Paulo state, at a cost of $300m. The gas from the processing unit will flow through a pipeline to Taubate, also in Sao Paulo state, where it will be connected to a pipeline from Campinas near Sao Paulo city to Rio de Janeiro.