Mensa is located 140 miles south-east of New Orleans and encompasses Mississippi Canyon blocks 686, 687, 730 and 731. The water is approximately 5,300ft-deep.

Drilling

The discovery well was drilled using Sonat’s drillship, Discoverer Seven Seas. One delineation well has been drilled and two remaining production wells are also planned. They will be drilled by the Transocean semisubmersible, George Richardson.

Reserves

The target reserves are in the Upper Miocene ‘1’ sand, at a depth of approximately 15,500ft. The average net thickness is approximately 100ft. Ultimate recovery from the field is estimated at 720 billion cubic feet of natural gas.

The first Mensa well produced approximately 108 million cubic feet of gas per day. A peak production rate of 300 million cubic feet of gas per day was achieved in the second quarter of 1998.

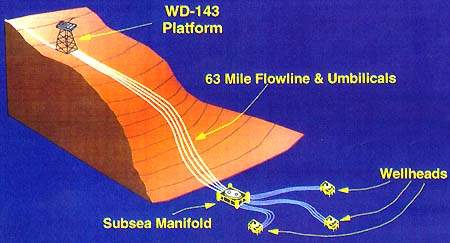

Subsea architecture

The subsea system consists of three wells, connected to a subsea manifold five miles away, which is in turn tied back via a 68-mile 12in flowline, to the shallow-water platform West Delta 143.

This is the longest tieback in the world, beating the previous record of 30 miles, established by the Troll Oseberg Gas Injection Project, in the Norwegian sector of the North Sea.

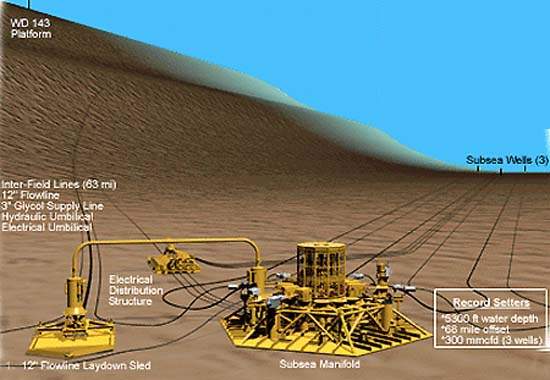

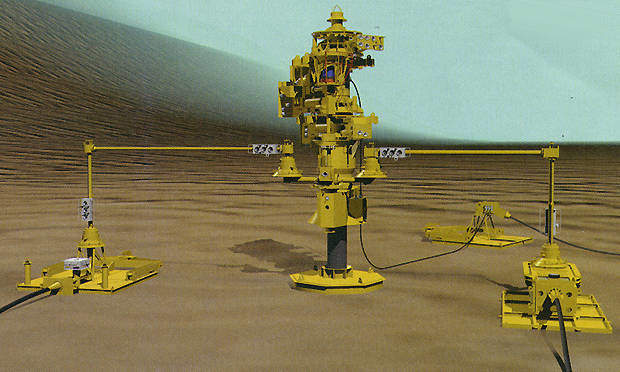

Subsea manifold and template base

The manifold / template base has four well-receiver slots and eight utility service slots, including hydraulic umbilicals, glycol injection and hydrate remediation.

The template base is located on the seafloor. It is not connected by piling to the seafloor, but relies on its mass for stability. It has a diameter of 94ft, is 12.5ft-tall and weighs about 200t.

The manifold sits on the template base. This is a separate assembly, which can be recovered independently of the template. It has a diameter of 16ft, is 16ft-tall and weighs about 50t.

Electrical distribution structure (EDS)

The EDS is located near the subsea manifold. It takes electrical power and communications signals from the platform at West Delta 143, amplifies the signal (which decreases over the 63 miles from the platform to the EDS site), and distributes it to each of the subsea wells, five miles away.

Subsea trees

The three subsea trees provide the interface between the wellheads and the infield flowlines. The trees are of a 10,000psi composite block guidelineless design, with a vertical-flow piping connection mandrel for mating with the well jumper.

Flowlines

The flowlines transport the gas from the wells to the manifold, then on to the platform at West Delta 143. The three infield 6in flowlines are five miles-long. They are made of carbon steel pipe and connected to the manifold with a stab and hingeover termination, and to the tree via a laydown sled and rigid jumper.

The 12in interfield flowline is 63 miles-long, made of carbon steel pipe and is connected to the manifold via a sled and jumper. It is connected to the West Delta 143 platform via risers.

Umbilicals

The hydraulic umbilicals are constructed of carbon steel, with zinc coating. They supply the hydraulic fluid and chemical injection (glycol).

There are three seven-line, five-mile infield hydraulic umbilicals and one three-line, 63-mile interfield hydraulic umbilical.

The electrical umbilicals are double-armoured cable and transmit electrical power and signals between the master control station on the West Delta 143 platform and the electrical distribution structure. There are three five-mile, infield electrical umbilicals and one 63-mile interfield electrical umbilical.

The 3in glycol supply line supplies glycol to the subsea manifold, where it is distributed to the various wells.

Master control station

Located on West Delta 143, this computer-based system monitors operational status of wells and other subsea equipment and has the capability to open and close the wells.