The Mariner East Project is a pipeline, processing and export project constructed in three phases; Mariner East 1, Mariner East 2 and Mariner East 2X, by Sunoco Logistics Partners (now Energy Transfer Partners).

The project covers a total area of 19 acres and is developed to transport natural gas liquids (NGLs) such as propane, ethane and butane from the Marcellus and Utica shale regions in Western Pennsylvania, West Virginia and Eastern Ohio to the Marcus Hook Industrial Complex (MHIC), located in Southeastern Pennsylvania.

NGLs are processed, stored and chilled at the MHIC, and further distributed to local, domestic and international customers. The MHIC serves as an off-take outlet for the Mariner East 1 pipeline system.

The project was announced in 2012 and the first transport of ethane from Mariner East 1 was accomplished in December 2014, whereas the first transport of propane from the pipeline was achieved in March 2016.

Construction works for Mariner East 2 began 2017 and the project came online in December 2018. Overall investment in the Mariner Phase 2 project is approximately $2.5bn.

The Mariner East 2X pipeline is expected to be operational by the end of 2019.

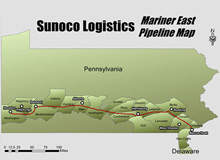

Mariner East Project pipeline route and capacity

The Mariner East 1 underground pipeline originates from Markwest Energy Partner’s Houston Processing and Fractionation Complex and terminates at the MHIC.

The pipeline is approximately 300 miles (482km)-long and incorporates 8in diameter pipes, except for the 51 mile (82km) stretch between Washington County and Westmoreland County, where 12in diameter pipes are used.

Mariner East 2, also known as the Pennsylvania Pipeline Project, originates from the processing and fractionation complexes in Ohio, West Virginia and western Pennsylvania, and terminates at MHIC. The underground pipeline follows the Mariner East 1’s right-of-way and integrates 20in diameter pipes. It is 350 mile (563km)-long, stretching 23.6 miles (38km) in Chester County and 11.4 miles (18.3km) in Delaware County.

Current designed capacity for Mariner East 1 is 70,000 barrels per day (bpd), whereas the designed capacity for Mariner East 2 is 275,000bpd, which could be expanded to 450,000bpd by installing additional pump stations based on future market demands.

The Mariner East 2X pipeline system will have a capacity of 250,000bpd.

Pennsylvanian NGL transportation pipeline construction details

After the commissioning of Mariner Phase 2, the Mariner Phase 1 will be used to exclusively transport ethane.

Mariner East 1 is provided with 16 pump stations, three meter sites and 44 valves sites, whereas Mariner East 2 requires no more than five pump stations for the initial phase.

The main control centre for the pipeline is located in Sinking Spring near Reading, Pennsylvania. Pipelines are inspected with X-ray technology during the welding phase, provided with protective bonded-epoxy coating and cathodic protection systems, and are monitored with inspection tools known as smart pigs.

The Mariner East 2 project also involved the construction of additional facilities at MHIC in order to accommodate the extra capacity. Two propane tanks with a combined storage capacity of 1.5 million barrels, a 600,000-barrel butane tank and a 300,000-barrel ethane tank are installed at the site.

Construction methods employed for the installation of the pipelines for both phases are the open-cut method and the drilling method, incorporating either horizontal boring or horizontal directional drilling.

Ethane sales and anchor shipper agreements

In September 2012, Sunoco Logistics Partners signed two separate 15-year agreements with Ineos Europe and Range Resources Corporation. Based on the agreements, Range Resources Corporation became the anchor shipper, whereas Ineos Europe will purchase the ethane produced from the project.

Benefits from the Mariner East Project

An economic impact study completed by Econsult Solutions in January 2018 stated that the Mariner East project will generate approximately $9.1bn in Pennsylvania’s economy and create approximately 57,070 jobs, with earnings of $2.7bn.

Contractors involved

Flour was contracted to provide project management services during the construction of the terminal facilities at the MHIC under the Mariner East Phase 2 project. The company served as the engineering, procurement and construction contractor for the Mariner East Phase 2 project.

Pipes for Mariner East 1 were produced at US Steel’s McKeesport facility in Pennsylvania, and coated at the Durabond facility in Duquesne, Pennsylvania.

The air permit application for Mariner Phase 2 project was prepared by Tetra Tech.