The Aasta Hansteen development project includes the production of natural gas from the Aasta Hansteen offshore field in the Norwegian Sea, approximately 300km from Nordland, Norway.

Development of the production field was undertaken by Statoil Petroleum (51%), Wintershall Norge (24%), OMV (Norge) (15%) and ConocoPhillips Skandinavia (10%).

The field is estimated to contain approximately 40 to 60 billion standard cubic metres of gas and 5.6 million barrels of condensate.

The cost of development for the Aasta Hansteen project is around $4.6bn (NOK 37.5bn).

Construction works related to the development of Aasta Hansteen production fields began in April 2014.

First gas for the Aasta Hansteen gas field was achieved in December 2018.

Norway is the second biggest exporter of gas in the world after Russia. It intends to develop a production hub in the Norwegian Sea by developing the Aasta Hansteen, Linnorm and Zidane discoveries.

Discovery of the Norwegian North Sea field and and background details

Formerly known as Luva, the Aasta Hansteengas field is located 186 miles offshore in the Norwegian North Sea. It is situated in blocks 6706/12 and 6707/10 at a water depth of 4,265ft (1,300m). It lies in Production License 218.

The Aasta Hansteen field was discovered in 1997. It was initially operated by BP, which discovered gas in deep waters (1,274m) in the Vøring Basin of the Norwegian Sea.

Equinor acquired the field in 2006 and discovered gas at two more prospects named Haklang and Snefrid South in 2008.

In March 2012, the Luva field was officially renamed after Aasta Hansteen, a campaigner for women’s rights in Norway.

Aasta Hansteen gas field development details

In 2008, the Norwegian Petroleum Directorate (NPD) issued the drilling appraisal well (6706/12-1) at Aasta Hansteen gas field, which was drilled by Transocean Leader.

Equinor submitted the plan for development and operations to the Ministry of Petroleum and Energy in December 2012 and received approval in 2013.

The production license 218 for the Aasta Hansteen gas field development was granted in 1994 and is valid untill 2041.

Development and production exemption was granted by the NPD for the Snefrid Nord gas field in October 2017.

The NPD granted approval for the start of gas production at the Aasta Hansteen facility in August, 2018.

Spar platform to be used at Equinor’s North Sea gas field

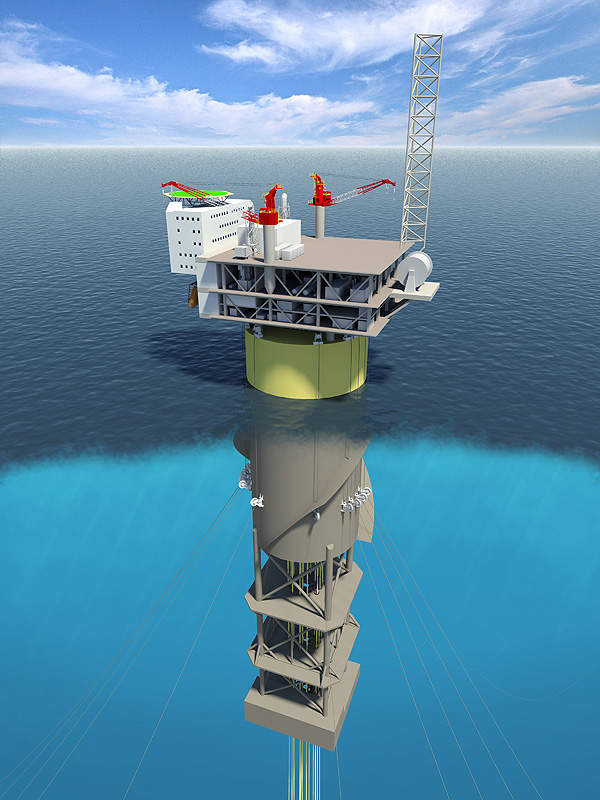

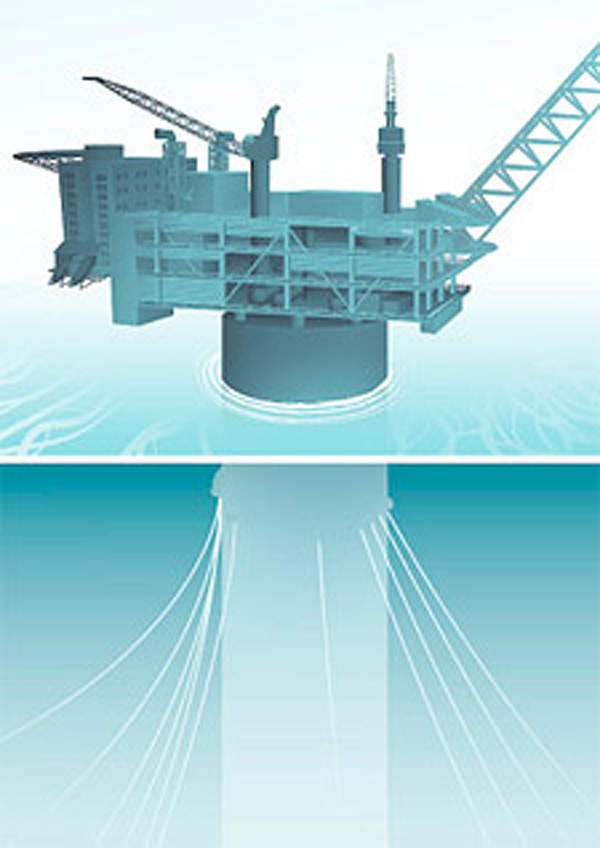

A spar platform, called Aasta Hansteen, was towed to the field in April 2018. It is the world’s largest and first spar platform in the Norwegian Continental Shelf.

The total weight of the floating, production, storage and offloading platform (FPSO) is 70,000t, which is installed at a depth of approximately 1,300m.

The floating platform features a processing facility, a single vertical cylinder, a supporting conventional deck and accommodation quarters for permanent crew working around the clock at the facility.

A spar platform is a type of FPSO consisting of a vertical column moored to the seabed. It includes topsides installed with gas processing facilities and a lower substructure or hull. The topside facility of the spar, with a weight of 24,000t, has the capacity to produce 23 million cubic meters of oil and gas per day. The dimensions of the topside are 100 x 50 x 56m.

The hull of the spar has a storage capacity of 160,000 barrels of condensate.

In April 2017, the spar hull was transported by a 275m and 79m wide heavy transport vessel named Dockwise Vanguard from Hyundai Heavy industries (HHI) shipyard, South Korea. The topside of the spar was transported by Dockwise White Marlin from HHI shipyard. Both topside and the hull were delivered at the end of 2017.

Exportation pipeline details

Gas produced from the Aasta Hansteen gas field is transported by a 480km-long Polarled pipeline that is connected to a gas substation at Nyhamna in Møre og Romsdal and is then exported to Europe.

Polarled pipeline, which was completed in 2015, has a diameter of 36in and a capacity of transporting 70 million cubic meters per day. It is operated by Gassco and is connected to different fields located in the Norwegian Sea.

Contractors involved with the Aasta Hansteen development project

Gassco conducted an impact study on the export pipeline from the Luva (now Aasta Hansteen) field to Nyhamna. IKM Ocean Design was awarded a pipeline front-end engineering and design (FEED) contract for the Aasta Hansteen deep-water field in April 2012.

In March 2012, Aker Solutions and Technip were awarded a FEED contract to design the world’s largest spar platform for the Aasta Hansteen (Luva) field.

The scope of the contract includes design, planning, procurement, construction and transportation of a spar hull and the mooring systems. It also includes design of the steel catenary risers.

Statoil (now Equinor) awarded the engineering, procurement, installation and commissioning (EPIC) contract worth $1.1bn to Hyundai Heavy Industries (HHI), South Korea for topside facility of the spar FPSO in January 2013. HHI is also the provider for hull/substructure of the spar.

HHI awarded the sub-contract to Lankhorst Ropes for providing deepwater mooring ropes for spar installation at the Aasta Hansteen field in 2014. HHI further sub-contracted Boskalis for the transportation of the hull and topside from HHI shipyard in South Korea to Aasta Hansteen gas field, Norway. The transportation work was completed by Dockwise, a wholly owned subsidiary of Boskalis.

The FEED study for the topsides of the spar was completed by McDermott in 2018.

Subsea7 was awarded a contract worth $200m by Equinor to deliver subsea umbilicals, risers and flowlines (SURF) for the field in February 2013.

GE was contracted for the supply of advanced aero-derivative gas turbine technology for the field in May 2013.

ABB was selected as an internal and external systems integrator of telecommunications for the offshore installations of the Aasta Hansteen field.

In July 2015, ASCO was awarded a contract for supply base services to support Equinor’s drilling activities and operations at the Aasta Hansteen field.

PG Flow Solutions supplied a hypochlorite pump skid for the Aasta Hansteen platform in March 2018. Delivery of a large chemical injection module and sump pump to this same installation was concluded in 2015.

Kværner was involved in the mechanical work related to the installation of the hull of the spar. The work included welding of the hull and tire connection and installation of pumps and fittings for riser pipes and connection of systems.