The Liuhua oil fields joint development project includes the development of the Liuhua 16-2, 20-2 and 21-2 oil fields located offshore China. The three fields lie in the South China Sea in water depths from 380m to 430m.

China National Offshore Oil Corporation (CNOOC) is the project operator.

Liuhua oil fields location

The Liuhua oil fields lie in the Baiyun Sag at the centre of the Pearl River Mouth Basin of the South China Sea.

Baiyun Sag is one of the biggest sub-basins of the Pearl River Mouth Basin. It has emerged as a new potential area for deepwater exploration of crude oil in the South China Sea.

Liuhua oil fields discovery, geology and reserves

The Liuhua 16-2 was discovered in May 2010 and contains 67m-thick oil pay zones. Located in the north-eastern part of Baiyun Sag, it is the first oil discovery to be made in the region. The field reservoir is made of lower Miocene and lower Zhujiang marine sandstone. The reservoir cap is made of the thick upper Zhujiang marine mudstone.

The Liuhua 20-2 field was discovered by the LH20-2-1 discovery well in May 2015. The well was drilled to a depth of 2,970m and encountered 35.2m-thick oil pay zones. It was tested and flowed at the rate of 8,000 barrels of oil per day, with a crude oil density of 0.75.

The Liuhua 21-2 field was also discovered in 2015 by the LH21-2-1 discovery well. Drilled to a depth of 3,000m, the well encountered 38m-thick oil pay zones.

The Liuhua 20-2 and Liuhua 21-2 fields are estimated to contain combined proven oil reserves of more than 70 million m³.

Liuhua oil fields joint development details

The Liuhua oil fields are planned to be developed using the HYSY119 floating, production, storage and offloading (FPSO) vessel. The FPSO vessel will have a design life of 30 years and will be deployed at the Liuhua 16-2 oil field.

A steel-cutting ceremony for the FPSO was held in October 2018. The FPSO will feature an offloading system comprising crude oil and liquefied petroleum gas offloading reels, a tandem mooring system, a hydraulic power unit and equipment controls.

It will also be equipped with a compressed air system comprising two 235kW instrument air compressors and a large adsorption air dryer, as well as 310t linear winch, a storage winch and two 100hp hydraulic power units.

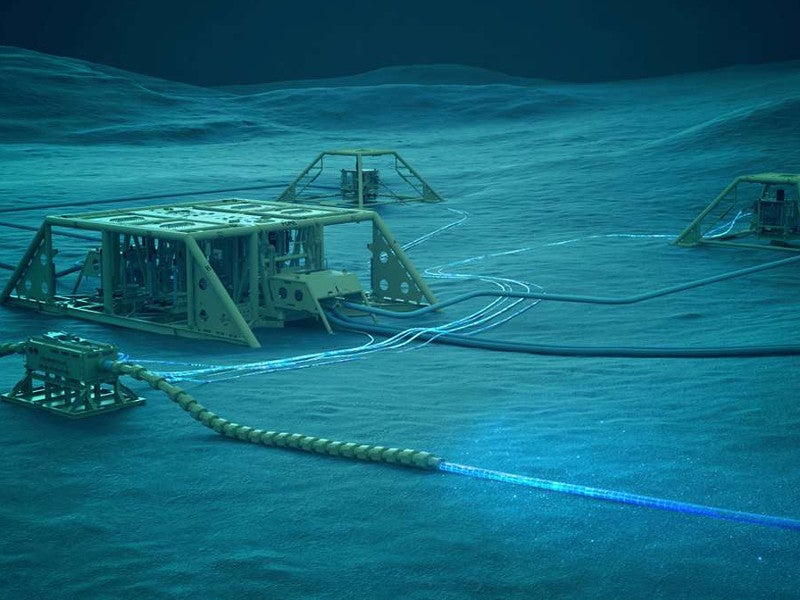

Subsea equipment details

The subsea equipment for the field will include 26 enhanced horizontal Christmas trees (EHXT), wellheads, subsea control systems, manifolds and tie-in systems.

More than 115km of dynamic and static power umbilicals comprising bundled cable and fibre optic systems will connect the subsea equipment with the FPSO.

The Liuhua 16-2 umbilical will be manufactured using Aker Solutions’ OsciLay production method, which enables the manufacturing of long or heavy umbilicals.

Contractors involved

Qingdao Beihai Shipbuilding Heavy Industry (Qingdao Beihai) is responsible for constructing the HYSY119 FPSO.

Qingdao Beihai subcontracted Tamrotor Marine Compressors to supply a compressed air system for the FPSO.

TechnipFMC was contracted to supply, install and commission subsea equipment for the project, while Royal IHC was awarded an engineering, procurement and construction contract for the FPSO offloading system.

Aker Solutions will supply power umbilicals for the project under a Nkr350m ($41.7m) contract, while SBM Offshore will supply a turret mooring system for the FPSO.

CCPGE was contracted to carry out vibration analysis for the reciprocating compressor packages of the FPSO, while DMAR Engineering carried out pre-front-end, engineering, design (FEED) studies, as well as FEED verification of the field development.

PH Hydraulics & Engineering is supplying winches and power units for the project.