Lingshui 17-2 is a deepwater gas field located in water depths of 1,500m in the South China Sea, offshore China. Owned and operated by China National Offshore Oil Corporation (CNOOC), it is the first independent ultra-deepwater discovery made in the region.

The field was launched for development in June 2018 with an estimated investment of RMB20bn ($3.12bn). It is expected to meet the growing energy needs of China, which is heavily dependent on imported oil and natural gas. It is expected to commence production in 2020.

Lingshui 17-2 gas field location

The Lingshui 17-2 gas field is located in the eastern part of the Lingshui Sag of the Qiongdongnan Basin, approximately 150km south of Hainan Island, in the South China Sea.

The Qiongdongnan Basin also holds the Lingshui 25-1, Lingshui 18-1 and Lingshui 18-2 gas discoveries. All the discoveries are distributed in straight strips with a horizontal span of approximately 120km.

Lingshui 17-2 gas field discovery details

The Lingshui 17-2 gas field was discovered by the Lingshui 17-2-1 discovery well in September 2014. The well produced 56.5 million cubic feet of gas a day.

The well was drilled by the CNOOC 981 deepwater drilling rig, which is the first semi-submersible deepwater rig developed domestically. Built at an estimated cost of RMB6bn ($975m), the rig’s deck size is equal to that of a standard football field. It can operate in 3,000m of water and offers a drilling depth of 12,000m.

Geology and reserves

The Lingshui 17-2 gas field consists of eight separate gas reservoirs, each with between one and four gas layers with an average thickness of 293.3m. The Upper Miocene Huangliu Formation is the gas-bearing formation of the field.

Gas reservoirs feature a normal temperature and a normal pressure system. Each one has an independent gas-water system.

The field is estimated to hold more than one hundred billion cubic metres of gas. Some of the reserves are found in the Yinggehai Formation.

Lingshui 17-2 gas field development details

The Lingshui 17-2 gas field will be developed using a 110,000t semi-submersible production platform developed domestically. It will feature condensate storage capacity and will be capable of operating in water depths of up to 1,560m.

The platform will be anchored to the sea bed through 16 legs built with driven piles, chain and polyester rope. It will be equipped with a pressure relief valve, a rupture disc and pressure vacuum valve.

The project will also feature a domestically developed polyester cable mooring system and a steel catenary riser. A 95km-long submarine pipeline, as well as a downhole and submarine production system, will also be part of the field.

The subsea production system will include 11 horizontal subsea trees and 70km of umbilicals connecting to the semi-submersible platform. It will also include four subsea manifolds, topside, and subsea control system and a tie-in connection system.

In addition, a two-stage compressor skid and a three-stage compressor skid featuring two types of Ariel compressors will be part of the subsea system.

Contractors involved in the Lingshui 17-2 gas field

CCS was contracted to perform the classification survey for the semi-submersible production platform, as well as the 95km-long submarine pipeline and subsea production system for the Lingshui 17-2 gas field.

China Offshore Oil Engineering Corporation, (COOEC), a subsidiary of CNOOC, contracted CCPGE to carry out vibration analysis of the compressor skids.

COOEC subcontracted InterMoor to install mooring systems for the semi-submersible production platform. The scope of work includes project management, detailed design, installation and execution.

Wood Group was contracted by CNOOC to carry out a review of the subsea production system and gas export pipeline.

Aker Solutions was awarded a contract worth Nkr1.7bn ($206.31m) to supply the subsea production system and umbilicals for the field.

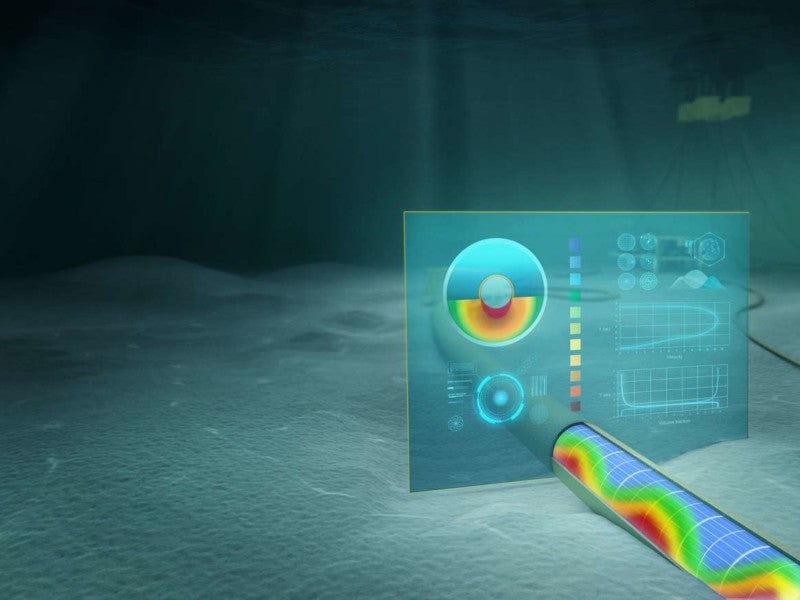

Kongsberg Digital was subcontracted by Aker Solutions to deliver a production management system that will provide real-time flow assurance at the Lingshui 17-2 gas field. The contract covers the wells, flowlines, and reception facilities of the field and will be designed using the company’s K-Spice and LedaFlow simulation technologies.