Operated by Maersk Oil, a decommissioning programme for the field was approved by the Department of Energy and Climate Change on 2 March 2016.

Leadon Field was discovered by the British National Oil Corporation in 1979 and was developed by Kerr-McGee following the drilling of an appraisal well in 1998. Production from the field started in 2001. Cessation of production application was filed by the operator in 2004.

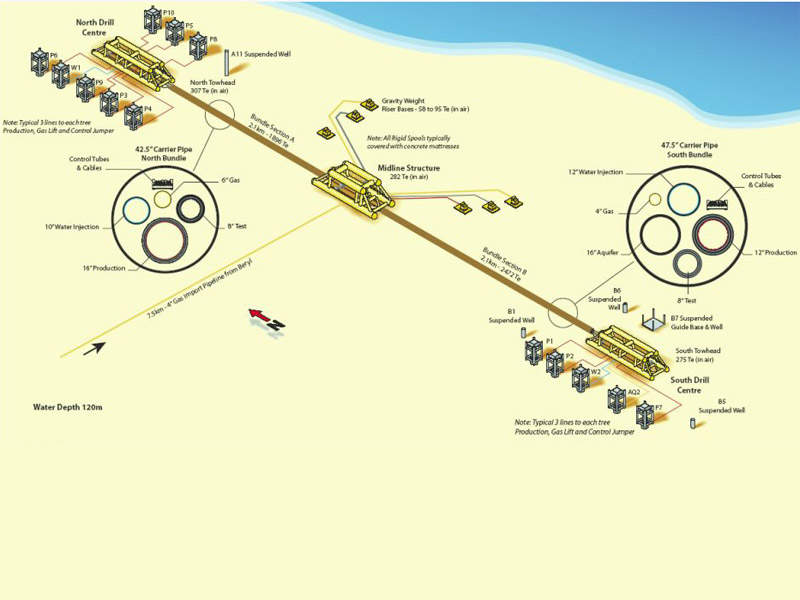

Leadon field infrastructure

Leadon Field was developed using an FPSO vessel named Global Producer III. Oil from the field was exported by offshore tankers and the gas produced was imported through a 4in diameter, 7.3km-long pipeline to the Beryl Alpha platform.

A total of 18 wells were drilled in two drill centres A and B, which are 4.2km apart. Drill centre A (north towhead) has seven production wells, one water injector and one suspended well, while drill centre B (south towhead) comprises three production wells, one water injector, one aquifer well and four suspended wells. Both the drill centres are connected to a mid-line structure by two bundle sections with diameters of 42.5in (1.08m) and 47.5in (1.21m).

The two towheads weigh 307t and 275t and include all the connections between the individual wells at the drill centres. The midline structure weighs 282t and is located halfway across the bundle length.

Leadon field decommissioning programme details

The decommissioning programme comprises safe removal of wellheads, towheads, the midline structure and riser bases. Supporting infrastructure such as concrete mattresses and grout bags will also be removed as part of the plan. Flowlines, connectors and pipeline bundle will be completely removed and transported onshore for recycling or disposal. The subsea wells will be plugged and abandoned.

The FPSO and mooring system have already been disconnected and relocated to the Donan field in 2006 in accordance with an agreement with DECC. Risers were removed and shipped onshore in 2007.

Large structures such as towheads will be cut into manageable lifts and will be recovered using heavy lift vessels. The wells will be plugged and abandoned in continuation to minimise the relocation cost of the drilling rig and conduct the operation more efficiently.

Pipelines, flowlines and umbilicals decommissioning

The pipeline bundle consists of two sections and is planned to be decommissioned in-situ with towheads and midline structure being removed and cut ends rock placed over the area to make the bundles over-trawlable. The bundles will be recovered in the future and will be inspected and monitored regularly.

The flowline PL1895 will be partially covered from Leadon’s midline section to the Beryl 500m zone with plans to recover the remaining section at a later date.

Grout bags and mattresses used for stabilising the remaining section of PL1895 will be removed later along with the remaining section of the flowline whereas spools, mattresses, grout bags and control jumpers will be removed and sent onshore.

Contractors involved

A contract was awarded to Petrex Developments to provide assistance for the decommissioning programme.

Harkand was awarded a multi-million-pound contract to provide two dive support vessels, the Harkand Da Vinci and Harkand Atlantis, for onshore and offshore activities. It will also provide project management and engineering services for well plugging and abandonment.

Harkand Atlantis will also perform barrier testing at 13 trees, remove production and gas lift spools at trees and towhead ends, as well as recover power and control jumpers and mattresses. The gas import pipeline will also be disconnected and flooded by the vessel.

An agreement was also reached with the Scottish Fishermen’s Federation to provide a guard vessel and also to assist in over-trawlability trials.