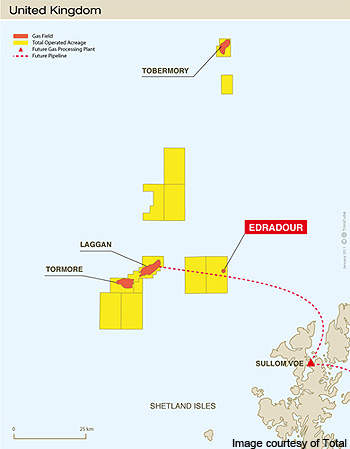

Laggan and Tormore are two gas and condensate fields situated about 125km north-west of the Shetland Islands in the UK. They are located 16km apart in the North Sea. The fields are owned by Total E&P UK (60%), SSE E&P UK (20%) and Dong E&P (UK) (20%). Total is the operator.

The Laggan-Tormore project involves the development of the two fields and the construction of a gas processing plant and export pipeline. The project is estimated to require a £2.5bn ($3.8bn) investment of which Dong contributed about £500m (approximately kr4.3bn). It created 800 jobs during construction and employs 70 personnel during operations.

The first production occurred in February 2016.

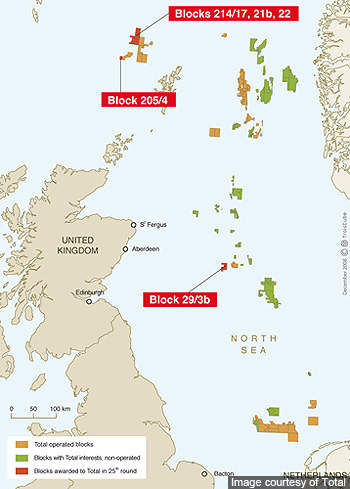

Location

The fields are located in the west of the Shetland area which contains 17% of the oil and gas reserve remnants in the UK. Laggan lies in Block 206/1a and Tormore in Block 205/5a, at a water depth of 600m (1,968ft).

Discovery

The Laggan field was discovered in 1986. It was licensed to Total in 1995.

The Tormore field was discovered in 2007. The discovery well (205/5a-1) recorded a test flow rate of 32mcf/d of gas at a depth of 3,936m (12,913ft). The condensate was 75 barrels per 1mcf of gas.

Reserves

The total field reserves are estimated to exceed one trillion cubic feet of gas and condensates (about 230 million barrels of oil equivalent).

Production

The two fields together are expected to produce 14 million cubic metres of gas and condensate a day at a peak production rate.

Field development

The field was developed as a long subsea tie-back to the new gas processing terminal (Shetland Gas Plant) that was built at Sullom Voe, about 100km from the field. The development plan was approved in March 2010.

Drilling

Appraisal drilling on the Laggan field was completed in 2004. Two appraisal wells were completed in 2004 and one of them (2006/4AZ) recorded a flow rate of 37.8 million cubic feet (mcf) of gas per day.

The first exploration well in the Tormore field was drilled in 2007. Appraisal drilling was carried out between 2008 and 2010.

The development drilling was carried out in two phases. The first phase began upon the completion of subsea template installation in 2012 and included drilling of seven production wells; four on Laggan and three on Tormore. Six of the seven wells drilled are new whereas the seventh well is an existing exploration well on Tormore, which is re-entered.

The second phase involves drilling of an additional well, the eighth, which will help to study the dynamic response of the field reservoirs.

The West Phoenix, a semi-submersible rig operated by Seadrill, was used for offshore drilling.

Subsea system

The subsea infrastructure includes eight subsea wells and two subsea production systems (one for Laggan and one for Tormore). The production systems comprise two six-slot production manifold templates. Fabrication of the manifold templates began in September 2012.

Heerema Marine was responsible for the transportation and installation of the production systems. Heerema used its Thialf heavy lift vessel for transportation and installation.

Pipeline

Two flowlines, each comprising an 18in diameter and 143km length, were built to transfer gas from the subsea production system to the Shetland Gas Plant (SGP).

Another pipeline, measuring 243km in length and 30in in diameter, called the Shetland Islands Regional Gas Export Pipeline (SIRGE), was built to export the processed gas further for final processing and sale. The SIRGE line has a capacity of 665mcf/d of gas.

The entire pipeline network required an estimated 200,000t of high-grade steel. The inner walls of the pipes are protected by a three-layer polypropylene anticorrosion coating, internal flow-efficiency coating and concrete weight coating.

Export

The produced gas is first sent to the Shetland Gas Plant through the two flowlines. The associated liquid hydrocarbons are exported to the Sullom Voe terminal.

The treated gas from the plant is exported to the Frigg UK pipeline in the North Sea through the SIRGE line. It is then transported to the St Fergus Gas Terminal for final processing.

Processing systems

The gas is separated from the liquids using a three-phase separator system at the SGP.

Contracts

Basic engineering of the field development, including the subsea infrastructure, gas treatment plant and the export pipeline, was provided by a joint venture of Ode and Doris Engineering. The JV was contracted by Total in March 2009.

Roadbridge was contracted by Total E&P for civil works associated with the site preparation for the gas processing plant, in March 2010.

The contract to supply the field subsea production systems was awarded to FMC Technologies in April 2010.

Subsea 7 was contracted in May 2010 for providing a number of subsea infrastructure items, including two control umbilicals, two piggyback rigid flowlines and other accessories. One of the umbilicals is 127km-long, the longest single length umbilical installed by Subsea 7. The second umbilical is 17km-long.

In February 2011, Subsea 7 awarded a contract to Nexans for the design, engineering and manufacture of subsea electro-hydraulic control umbilicals for the project.

The flow lines include an 8in mono ethylene glycol line and a 2in service line, extending to a length of 141km. The 8in pipe was supplied by Valorec Mannesman and the 2in pipe was supplied by Saltzgitter Mannesman International.

The contract is valued at more than $250m and includes installation, tie-ins and pre-commissioning of all the pipelines. Installation and pre-commissioning of the pipelines and umbilicals began in mid-2012.

Skema was contracted to design, manufacture, inspect and test LV distribution boards for the Laggan Tormore development project, in March 2012.

Kongsberg Oil & Gas Technologies was awarded a contract to provide operator decision support system for the project, in December 2012.

The 18in and 30in flowline pipes were supplied by Corus, under a £200m contract signed with Total in 2010. The installation of flowlines and onshore pipelines were carried out by Allseas UK.

The processing plant (SGP) was built by Petrofac’s Offshore Engineering & Operations (OE&O) unit. Wood Group was contracted to provide support services for the SGP, in March 2015.