The Kobra East & Gekko (KEG) field is located within the production licence (PL) 203 in the Alvheim area of the central North Sea, Norway. The water depth in the area is between 120m and 130m.

The KEG project enhances the current production capacity of the Alvheim FPSO significantly, facilitating an extended operational lifespan until 2040.

The KEG field is co-owned by the operator Aker BP having an 80% interest, and ConocoPhillips Skandinavia with the remaining 20% interest in the field.

The plan for development and operation (PDO) of the KEG field was approved by the Norwegian Ministry of Petroleum and Energy in February 2022, following its submission in June 2021. The project entails an estimated investment of Nkr8bn ($1bn).

The field started producing in October 2023, ahead of its scheduled time.

Kobra East & Gekko field discovery and reserves

The Kobra field was discovered by the well 25/7-5 in the Hermod Formation in 1997. The field structure comprises remobilised Palaeocene Hermod sands with high-quality reservoir properties. The field was developed in 2016.

Gekko was discovered by the well 25/4-3, approximately 10km south-east of Alvheim in 1974, and was later appraised in 2018 to encounter a thin 6.5m oil column beneath a large gas cap. The sandstone reservoirs are present within the Palaeocene Heimdal Formation.

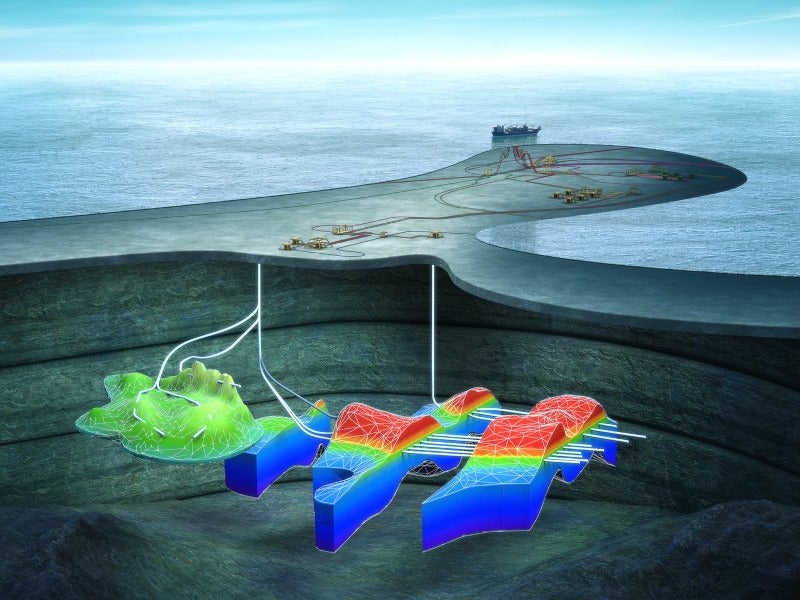

The Gekko development has been combined with the Kobra East development through an additional tri-lateral well.

The KEG field has estimated recoverable reserves of approximately 40 million metric barrels of oil equivalent (mmboe).

KEG field development details

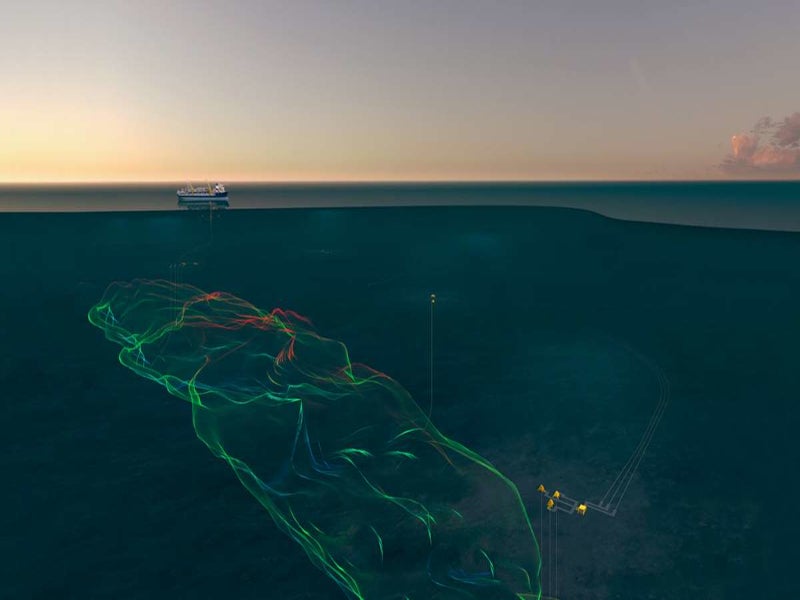

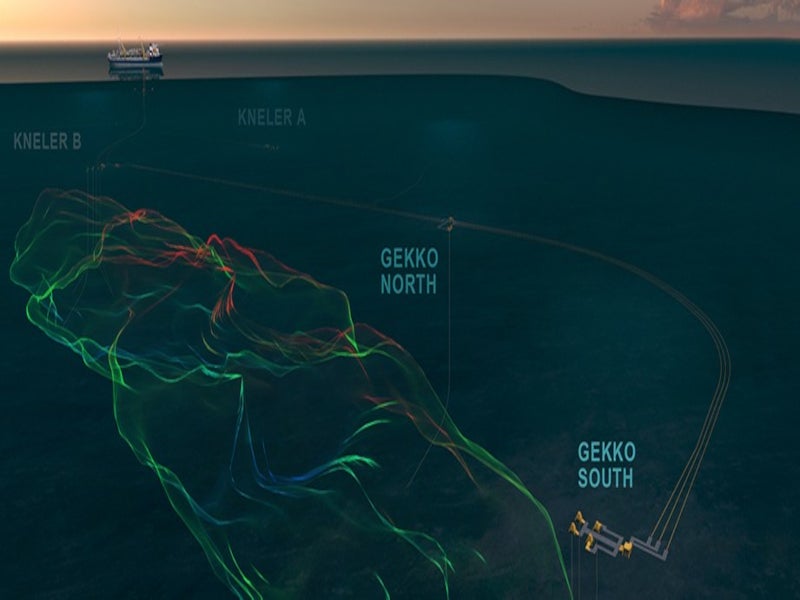

The Kobra East and Gekko fields were developed through the installation of subsea production systems, tied back to the existing Alvheim floating, production, storage, and offloading (FPSO) vessel situated approximately 8km away, via the existing Kneler B sub-sea manifold.

The field development required approximately 42km of drilling from four multi-lateral wells, which accounted for a major part of the project investment. The approach of drilling a multi-branch well instead of single wellbore wells in the reservoir increases the recovery from the fields. The drilling takes place from two locations, Gekko South and Gekko North.

The produced oil is processed and stored in the FPSO and later buoy-loaded to tankers while the processed gas from the FPSO is piped to the St Fergus gas terminal in Scotland via the British Scottish Area Gas Evacuation (SAGE) pipeline system.

The KEG project cut the CO₂ emissions per barrel by 50% and doubled the oil production from the Alvheim FPSO. The fabrication and installation of the subsea facilities for the project include the pipe-in-pipe-designed pipelines, umbilicals, subsea Christmas trees, structures, and subsea control modules.

Alvheim FPSO details

The Alvheim FPSO has a length of 252.16m, moulded breadth of 42m and moulded depth of 23.2m. The vessel has a design capacity of 120,000 barrels per day (bpd) of oil, 125 million metric cubic feet per day (mmcfd) of natural gas, and 560,000 barrels of oil storage capacity.

The FPSO was converted from a multi-purpose shuttle tanker named MST Odin at a yard in Haugesund, southern Norway, for use on the Alvheim oil and gas field.

The vessel became operational in 2008 and achieved 55,400 barrels of oil equivalent per day (boepd) of production in 2020 with a production efficiency of 96%.

Alvheim area details

With net proven reserves of approximately 71Mmboe, the Alvheim area comprises the producing Alvheim, Skogul, Vilje, Boyla and Volund fields along with other discoveries including Gekko, Froskelar, Caterpillar, Tyrving (formerly, Trine and Trell). The production from the area began in 2008.

Contractors involved in Kobra East & Gekko field development

Aker BP awarded contracts worth Nkr1.7bn to the subsea alliance among Aker Solutions, Subsea 7 and Aker BP for the engineering, procurement, fabrication and installation of the subsea production system and subsea umbilicals, risers and flowlines (SURF) for the KEG project in July 2021.

Subsea 7 subcontracted Corinth Pipeworks, the steel pipe segment of Cenergy, to provide high-frequency welding steel pipes for the project in September 2021.

Odfjell Drilling, a drilling company, was contracted to provide drilling services for the project in February 2022. The Deepsea Nordkapp, a semi-submersible rig, was used for the same.