For the first time, innovative subsea boosting technology was used to increase production in the Gulf of Mexico from wells on the King field. Located at a water depth of 1,700m, it is the deepest such installation to date, and lying 29km from the host platform, it is the longest booster subsea tieback to date. The King field is the first commercial application of this technology.

King is spread across Mississippi Canyon blocks 84, 85, 128 and 129. It is operated by BP, which has 100% equity in the project.

The field’s water depth varies between 1,600m and 1,800m (5,000ft to 5,400ft). Production from the project started in 2002 and the field produced an average 27,000boed in 2007.

King Field development

Initial field development plans were carried out by Amoco before it was subsumed into BP. The development was to be carried out in association with the King’s Peak field, based on five subsea wells producing through 6in and 10in pipe-in-pipe insulated flowlines and tied back to a truss spar production system. The project was also to include water injection facilities via 6in and 8in flowlines and steel catenary risers to three subsea water injection wells.

A processed wellstream from the spar was exported via two 16in pipelines to a gathering system tie-in points at Main Pass 225 and Main Pass 260.

Affected by oil prices, the King field underwent a development reappraisal. It is one of three fields producing from the Marlin TLP and represents more than half of Marlin TLP production.

The complex lies 18 miles from Marlin in the Viosca Knoll area, approximately 84 miles southeast of New Orleans.

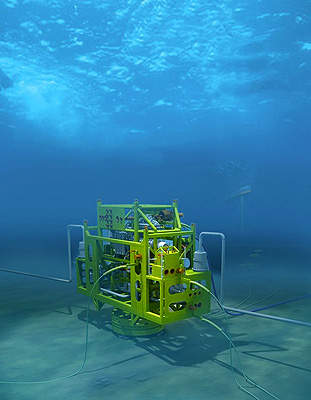

The project to retrofit two existing subsea wells with the innovative subsea booster pump to optimise oil recovery commenced in late 2007. This marked the first subsea multi-phase pump application in water depths greater than 3,000ft.

The two 1.5MW subsea pumps were placed some 15 miles from the Marlin TLP well. Two multiple application reinjection systems for the multiphase pumps were installed, enabling flow from well directed externally to new subsea hardware and reinjecting into existing flowlines. The pumps are powered via wet mateable connectors supplied by Tronic.

King Field contracts

The contract to supply the pumping system was won by Aker Kvaerner Subsea. In total, Aker Kvaerner supplied three systems (for two subsea pump stations and one spare) at a total value of NKr220m.

The total contract included modules with manifolds, variable speed drives, topside and subsea control systems, topside lube oil and hydraulic power units, and high voltage connectors and jumpers. The pump station systems were manufactured at Aker Kvaerner Subsea’s facility in Tranby, Norway.

Subsea service umbilical

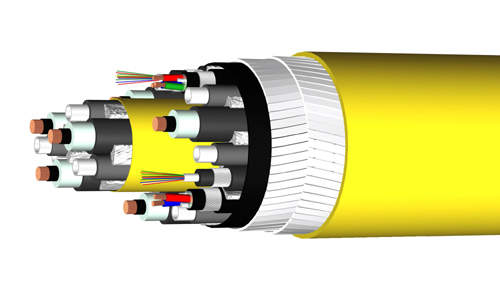

BP awarded industrial cable supplier Nexans the $15m contract for the design and manufacture of the world’s first subsea service umbilical that integrates a high-voltage cable rather than having to resort to separate umbilical and power cables.

The deepwater 16-mile-long power umbilical consists of a main dynamic and an infield umbilical.

Apart from low and high-voltage electrical power, the umbilical also provides oil for the pump lubrication, chemicals for injection to prohibit the formation of hydrates and fibre-optic communications. The conductor to the booster system carries 24,000V.

In all, three wells were boosted – D6, D5 and D3. Of the six-core power umbilical three of the cores were run to D5 and D3 while the remaining three continued to D6.

The booster assembly consists of a manifold base skid supporting the pump module itself. Each of the 70t assemblies were located over 3.6m-diameter suction piles.

The design specifies MPC-335-50 Bornemann pumps, which can pump at 75,000bpd and give a 50 bar differential pressure. Inlet pressures at the King wells range from 48 bar to 127 bar.