Kaikias deep-water project straddles two outer continental shelf lease blocks of the high-quality Mars-Ursa oil basin, known as MC-811 and MC-812.

The oil field is located in 1,395m of water, 201km away from the Louisiana coast in the Gulf of Mexico, US.

Royal Dutch Shell subsidiary Shell Offshore currently serves as operator of the project and holds 80% working interest.

The remaining 20% is owned by MOEX North America, a wholly-owned subsidiary of Mitsui Oil Exploration Co (MOECO).

The final investment decision to develop the project was made in February 2017, and first production from the site is expected in 2019.

Kaikias’ close proximity to Shell’s existing infrastructure makes it a low-cost and high-value project for the company.

Production from the company’s global deep water operations is expected to reach 900,000boe/d by 2020.

Kaikias discovery and appraisal

Kaikias was discovered in August 2014, with initial appraisal activities following in August 2015.

The appraisal well was drilled to a depth of 34,500ft and found more than 300ft of net oil pay.

Both vertical and horizontal drill bits were ultimately used, in order to avoid hazardous salt formations.

Kaikias oil field reserves

The Kaikias field blocks are estimated to hold more than 100 million barrels of oil equivalent in recoverable resources, with scope for further exploration.

Kaikias deep-water oil field development

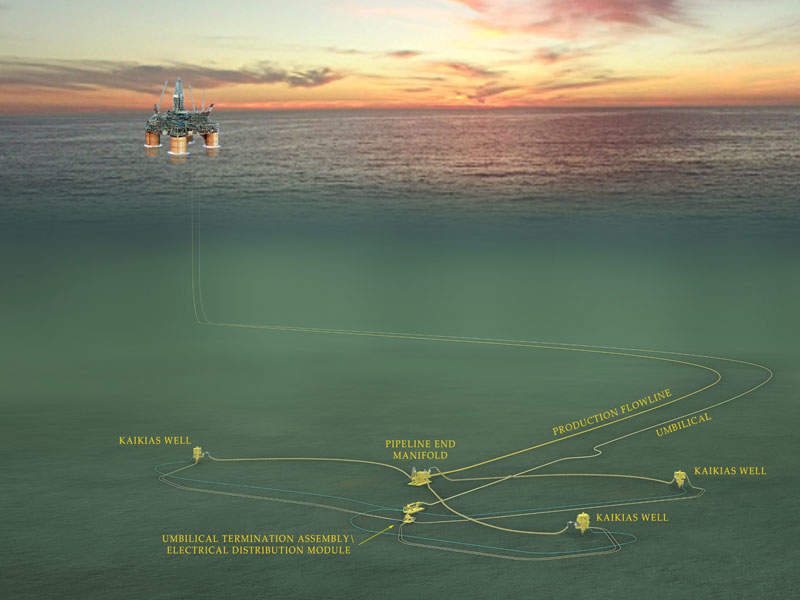

The Kaikias deep sea oil project is planned to be developed in two phases, as a subsea tieback to Shell’s Ursa oil and gas production hub located in the same Mars-Ursa basin.

Shell already owns and operates three infrastructure hubs in the area.

Phase one of the development will include three production wells, which will be tied back to the Ursa platform using a single flowline. The first phase will produce 40,000 barrels of oil equivalent a day (boe/d).

Shell will redevelop the existing exploration and appraisal wells instead of drilling new production wells, which will help the company achieve an approximate 50% reduction in the overall development costs, while also facilitating the early commercialisation of the project.

The existing oil and gas processing equipment on Ursa eliminates the need for additional top-side modifications, thus creating further savings in operating costs.

Contractors involved

TechnipFMC was contracted to supplya subsea production system (SPS), and subsea riser, jumper and flowline (SURF) equipment for the development’s first phase.

Technip will supply and install the SPS and SURF equipment using its compact pipeline end manifold and horizontal connection system technologies as part of the arrangement, marking the first time such technology has been implemented in the deep-water Gulf of Mexico.

The company was also involved in the front-end engineering and design (FEED) process of the first phase of the project.