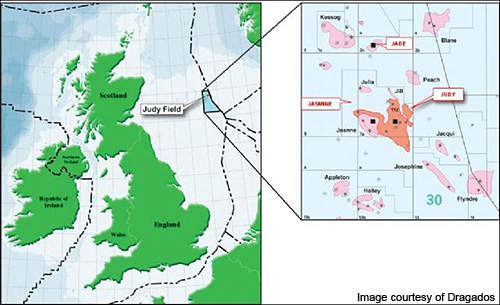

The Jasmine field is situated in blocks 30/6 and 30/7a of the central North Sea. The gas and condensate field lies at a water depth of 266ft and is considered to be the UK’s largest discovery since the mid-1990s.

ConocoPhillips is the operator of the field with 36.5% interest. Eni (33%) and BG Group (30.5%) are the other licensees in the project. Jasmine lies close to ConocoPhillips’ producing fields, Jade and Judy.

In October 2010, the UK government approved the development of the Jasmine field. The first production from the field was achieved in November 2013.

The field has a gross production capacity of 140,000boepd. It is expected to produce approximately 40,000boepd in 2014.

Jasmine field details

The high temperature and high-pressure reservoir of the field is of the Triassic age. It contains a 2,300ft deep hydrocarbon column in the Skagerrak formation. Recoverable resources present in the reservoir are estimated at 100mmboe.

The Jasmine field was discovered in 2006 by the discovery well 30/6-6. An exploration well 30/6-06 and sidetrack well 30/6-06Z found hydrocarbon reserves in the reservoir.

In 2007, ConocoPhillips initiated appraisal drilling at the field. Appraisal well 30/6-07 was drilled and encountered a 550ft hydrocarbon column. Tests conducted on a sidetrack well, 30/06-07Z, registered good flow rates.

An extension of the field was discovered in 2008 by the exploration well 30/6-7. The extension is located 3km north-east of the field and was drilled by the Ensco 102 drilling rig.

Two sidetrack wells, 30/6-7Y and 30/6-7X, were later drilled to establish the presence of hydrocarbons in the extension.

The field was developed in three phases. In the first phase, the West Limb and the Northern Terrace sections of the field were developed. Drilling activities for the first phase were started in 2011.

Installation of the Jasmine wellhead platform, the Judy riser platform and the multiphase Jasmine pipeline will be carried out in the first phase.

A 38-bed permanently manned accommodation and utility platform called Jasmine living quarters (JLQ) was also part of the Jasmine field development. The JLQ features a four-leg 3,300t jacket with four piles.

The topsides of the platform weigh 3,100t. The platform features two lifeboats and a helideck.

A pipeline bundle system consisting of two 4.1km bundles connects the JWHP and the JRP. The system consists of a 16in diameter production pipe inside a 20in sleeve pipe, two subsea isolation valves, and mid-line and end-line spools.

Jasmine wellhead platform

The Jasmine field uses the Jasmine Wellhead Platform (JWHP) for production. The platform is supported by a four-leg 5,440t jacket and nine piles. It contains 24 slots and topsides weighing 5,500t.

The platform is connected to the JLQ through a 480t bridge, 100m in length. It has a capacity of 300MMSCFD of gas and 90,000b/d of condensate. A test separator and flare are also part of the platform.

Judy riser platform

A new riser platform called the Judy riser platform (JRP) was added to the production facilities at the Judy field. The JRP is supported by a four-leg 5,400t jacket with eight piles. It contains 12 slots and topsides weighing 6,200t.

The JRP is connected to the existing Judy platform via a 100m-long bridge, weighing 670t. It features primary oil and gas separation facilities, flash gas compression and product cooling facilities.

Contractors

WorleyParsons conducted a detailed engineering study for the new facilities at the Jasmine field. It was contracted in November 2010 to conduct a FEED study and provide procurement services for the JWHP, JRP, JLQ, the multiphase pipeline and other facilities. WorleyParsons earlier conducted concept and feasibility studies for the project.

ConocoPhillips contracted Subsea 7 in November 2010 for manufacturing and installing the Jasmine pipeline. Subsea 7 also installed an 8.9km power and communications cable between the JRP and the JLQ, along with other umbilicals and tie-ins.

ConocoPhillips awarded a contract to Halliburton in December 2010 for the procurement of directional drilling, logging-while-drilling (LWD) and surface data logging (SDL) services on the Jasmine field.

AMEC was contracted for fabrication and construction of the riser platform. The company was responsible for the assembling and commissioning of the new Jasmine facilities.

The jackets for the JWHP and JRP were constructed by Rossetti Marino.

In April 2010, Dragados Offshore was awarded the contract for construction of the topsides of the JWHP and JRP. Scope of work for Dragados included engineering and construction of the jackets. Dragados also constructed the connecting bridge between the JWHP and JRP.

Italy’s Saipem was responsible for the transport and installation of the platforms.