The Hejre oil and gas field is located in the central part of the North Sea. It lies 300km away from the Danish coast in License 5/98 at a water depth of 70m.

DONG Energy is the operator of the field and holds a 60% interest in the field. Bayerngas Norge holds the remaining 40% interest.

The field was planned to be developed through the Hejre platform and expected to come online in late 2015. The engineering, procurement and construction (EPC) contract for the platform was awarded to Technip and Daewoo Shipbuilding & Marine Engineering (DSME).

In March 2016, Dong Energy and Bayerngas announced their decision to cancel the EPC contract as the consortium did not meet the terms of the contract. A settlement on the EPC contract was reached in May 2017, according to which DSME will be responsible for the dismantling and disposal of the platform.

The partners are currently evaluating alternatives for the development of Hejre.

Discovery of the Danish oil and gas field

The Hejre field was discovered by the Hejre-1 well in 2001. The well was drilled by the Ensco 101 jack-up rig to a depth of 5,265m.

The Hejre-2 well was drilled in 2005 by the Ensco 101 jack-up rig to a depth of 5,399m. The drilling activities confirmed the presence of oil.

Oil was produced at favourable production rates along with associated gas.

Geology and reserves at the Hejre reservoir

The Hejre reservoir is made of the upper Jurassic reservoir sandstones, which are similar to the UK Fulmar and Norwegian Ula formations.

The reservoir lies at a depth of 5,100m with oil and gas found in the subsoil in a geological layer consisting of sandstone. It is a high-temperature and high-pressure (HTHP) reservoir with a pressure of 1,000 bar and a high temperature of 160°C.

Field development

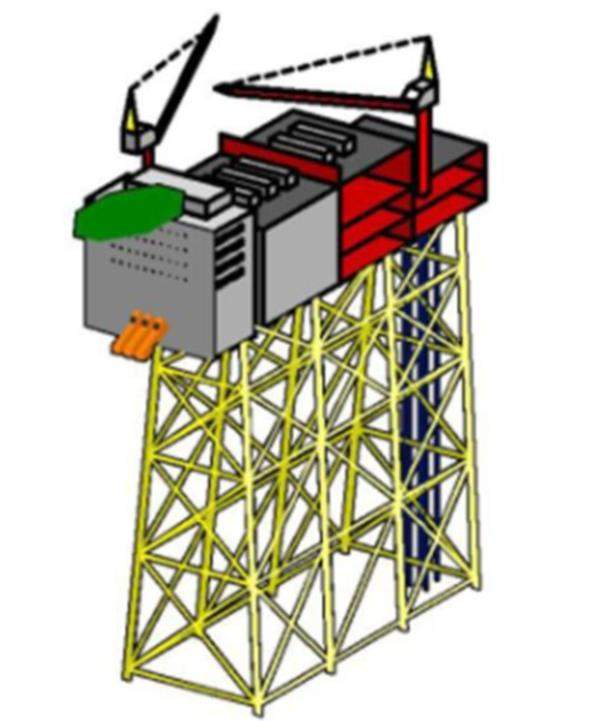

DONG Energy submitted a plan for approval to the Danish Energy Agency in November 2010. The plan was approved in October 2011. The HTHP nature of the field reservoir required a technically complex production system.

The development concept included a manned wellhead and processing platform. Five HTHP production wells drilled to a depth of 67m and tied back to the platform. The field was planned to be decommissioned at the end of its operating life.

Exporting oil and gas produced

The hydrocarbons produced at the field were planned to be exported onshore through two new pipelines.

A 90km pipeline was laid to carry live oil to the Gorm E platform. After going through initial processing, the oil was planned to be transported through existing pipelines to the Fredericia terminal onshore to process the NGLs. A new LPG gas plant and storage facility was planned to be built at the terminal to process the NGLs.

Sales gas was planned to be carried through a new 24km pipeline to the South Arne field.

Contracts awarded

COWI was contracted to prepare the environmental impact assessment study for the field. It was also involved in assessing the field’s development concepts.

Ramboll was responsible for carrying out the feasibility studies for selecting the development concept for the field. It carried out process simulations, material selection, risk evaluation and lifecycle cost estimation. It was also involved in the FEED tender preparation in 2010.

Aquaterra Energy was awarded a four-year drilling installation support services contract for the project in April 2014.