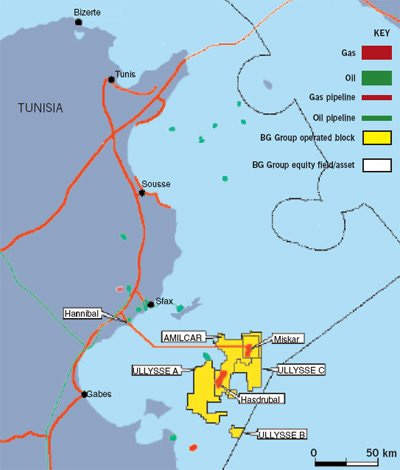

The new Hasdrubal onshore gas processing facility and the Liquefied Petroleum Gas (LPG) production facility will be located on the Tunisian coast between La Skhira and Sfax in Tunisia and is scheduled for completion in 2009.

The plant is being constructed in a 50/50 joint venture by British Gas Tunisia Limited (BGT) and Entreprise Tunisienne D’Activités Pétrolières (ETAP), the Tunisian state-owned oil and gas exploration and production company, to

exploit the Hasdrubal field, which is situated in the Gulf of Gabes about 110km east of Sfax at a depth of 62m.

The project is intended to increase production levels to meet the demand of the domestic gas supply in Tunisia, while still maintaining

supplies for generation of electricity.

NEW GAS PROCESSING PLANT

The field is part of a rich gas, condensate and associated oil rim within the nummulitic carbonate El Garia reservoir horizon. The onshore gas plant will be a gas conditioning train encompassing gas separation, mercury removal, gas dehydration using

molecular sieve, H2S/CO2 removal, export gas compression, condensate stabilisation, condensate storage and export systems.

The plant functions will include recycle gas compression, produced water removal, treatment and storage, cold flare system, HP flare and relief system, hot oil systems and dedicated power generation / distribution. The LPG plant will include LPG

extraction, using proprietary turbo-expander technology for dew pointing and LPG storage and export systems.

FRONT-END ENGINEERING AND DESIGN

Petrofac carried out Front-End Engineering and Design (FEED) for the development of the Hasdrubal field and also conceptual and pre-FEED work for the offshore and onshore facilities in the first half of 2006.

The intention is to develop the field with

a normally unattended installation, and produce hydrocarbons through a new multiphase export pipeline to onshore processing facilities that will be constructed adjacent to the existing BG Tunisia Hannibal plant 21km south of Sfax. In this way the two

gas plants can share common infrastructure.

A significant proportion of the gas processed at the Hannibal plant is already supplied, under a long-term contract, to Société Tunisienne de l’Électricité et du Gaz (STEG), Tunisia’s state electricity and gas company.

The Hasdrubal onshore facilities will export sales gas to the Tunisian gas grid and condensate to a storage facility via a new 67km condensate pipeline along the coast to La Skhira. The facilities will also produce separate liquid propane and butane

products for distribution by a local Tunisian company as cylinder gas.

CONSTRUCTION

In November 2006 Petrofac was awarded the $400m lump sum turnkey contract by ETAP to build the gas processing and LPG plant. The scope of the project covers project management, detailed design, procurement, construction, pre-commissioning,

commissioning, start-up and performance testing of the new gas plant. Petrofac will use a local construction and fabrication company, Pireco, as its main construction sub-contractor for the project.

The Hasdrubal project will be the first major project for the E&C division of Petrofac in Tunisia. Construction work will begin on the project in the first quarter of 2007 with completion scheduled for the middle of 2009.

BARCA POWER PROJECT

BGT is the largest producer of gas in Tunisia, supplying more than 50% of domestic gas demand from its 100% owned Miskar field in the Gulf of Gabes about 110km east of Sfax. Part of the reason for the new Hasdrubal gas facility stems from the Barca

Power Project, which is being developed by BGT in Sfax at a cost of $250m.

The 500MW Combined-Cycle Gas Turbine (CCGT) Barca power plant is due to be operational in the first quarter of 2007 adjacent to the Hannibal processing site. The plant will employ 50 personnel and use up to 120 million standard cubic feet of gas a day

from BG’s offshore interests in the Miskar Concession and, potentially, the Hasdrubal gas / condensate field. EPC contractors for the power plant include Enelpower, Ansaldo Energia and Alstom.