Hasdrubal oil and gas field is located 100km offshore Tunisia in the Gulf of Gabes. It lies in the 1,584km² Amilcar exploration permit at a water depth of 62m. The field came on-stream in March 2009.

BG Group is the operator of the field with 50% interest. The remaining stake is held by Tunisian state oil company Entreprise Tunisienne d’Activités Pétrolières (ETAP). African Development Bank Group provided a loan of $150m for development of the field.

BG is the biggest producer of natural gas in Tunisia. It meets more than half of the country’s natural gas demand, with the Hasdrubal and Miskar fields (also located in the Amilcar permit).

Combined production from the two fields is around 45,000 boed. BG is also the largest producer of liquefied petroleum gas (LPG) in Tunisia.

Discovery of the Tunisian oil field

Hasdrubal was discovered by Elf (Sofratep) in 1975 but was declared non-commercial.

BG drilled three appraisal wells, which confirmed the commerciality of the field. The first well, Hasdrubal-2, was drilled in 1994. In June 1997 a second appraisal well, Hasdrubal-3, was drilled and flowed at the rate of 21 million square cubic feet a day (mmscfd). The third well, Hasdrubal-4, drilled in June 1998 flowed at the rate of 4.6mmscfd and 1,800 barrels of oil.

In 2002, BG drilled the Hasdrubal South West-1 well which led to the discovery of light oil in the Tertiary El Garia formation. Drilled by the Key Manhattan rig, the well confirmed the presence of a southwest extension of the field.

Geology and reserves of the Hasdrubal reservoir area

Hasdrubal reservoir is of the early Eocene age and made of shallow nummulitic limestones of the El Garia formation. The El Garia formation reservoirs are known to hold significant hydrocarbon reserves in Tunisia and Libya.

The field is estimated to contain recoverable reserves of 260 billion cubic feet of gas and 25 million barrels of condensate.

Production, infrastructure and exportation of gas and oil at the Hasdrubal field

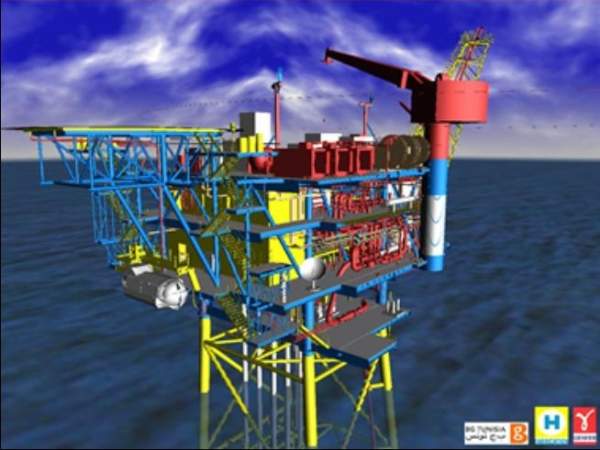

Hasdrubal is produced through three wells drilled from a normally unmanned platform called Hasdrubal A. The platform weighs 2,450t and is supported by a 1,000t, 70m long jacket.

The topsides of the platform measure 46 x 30 x 29m and weigh 1,450t. Five decks are part of the topsides.

Produced oil and condensate is exported through a 110km, 18in diameter multiphase export pipeline to the Hasdrubal onshore processing plant located near Sfax in Tunisia. The plant was built as part of the field’s development. It is located next to BG’s Hannibal plant to enable the sharing of infrastructure.

The Hasdrubal plant includes facilities for gas processing, mercury removal, gas dehydration and condensate processing. It processes the produced hydrocarbons to separate gas, oil, condensate and LPG.

A dedicated LPG storage terminal has been built at Gabes. Butane and propane processed at the LPG facilities of the Hasdrubal plant are sent to the terminal and sold in the domestic market.

Processed gas is distributed to the domestic market through the Tunisian gas grid. Oil and condensate are transported to the La Skhira Terminal through a 67km pipeline and exported to the international market.

Contracts awarded to companies involved with the Tunisian field

Petrofac was awarded a front-end engineering and design contract for the field in October 2005. Conceptual and pre-FEED work was also carried out by Petrofac. The construction contract for the onshore gas plant was also won by Petrofac.

Hasdrubal A construction contract was awarded to Heerema Fabrication Group in November 2007. Heerema was responsible for engineering, procurement, transport, installation and commissioning of the platform.

Saipem was responsible for manufacture, installation and pre-commissioning of the 110km offshore pipeline system from the field to the onshore terminal. Subsea Protection Systems was subcontracted by Saipem for concrete mattresses and dropped object protection covers for the project.

Hallin Marine provided its Quasar ROV to Saipem to lay the pipeline under a $1.3m contract. Quasar ROV was deployed from Saipem’s VOS Sympathy vessel for the project.

Scaldis-SMC was responsible for transportation and installation of the Hasdrubal platform. It used its Rambiz barge to transport all the components of the platform and install at the field.