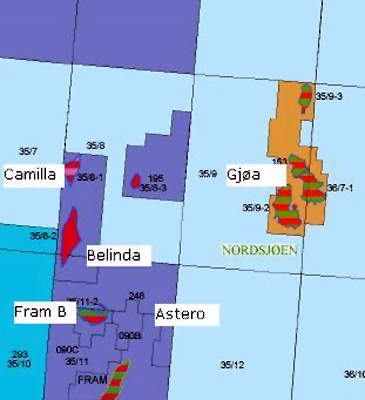

StatoilHydro’s Gjøa field lies in blocks 35 / 9 and 36 / 7 of the North Sea. The field was proven in 1989 and its reserves are estimated to be 82 million barrels of oil and 40 billion cubic metres of gas. Gjøa’s total development investments are estimated at Nkr29.3bn. After Snøhvit, this is the biggest project StatoilHydro has under development.

StatoilHydro is the operator of the field. Its licensees are Gaz de France (GDF) (30%), Petoro (30%), StatoilHydro (20%), Shell (12%) and RWE Dea (8%). GDF took over operations when the field came onstream in November 2010. Oil and gas production was started in November 2010.

In March 2010 GDF signed a contract with OH Meling & Co to supply a new supply vessel named Siddis Supplier for the Gjøa field. The contract was signed for eight years with an option to extend to another three years. The vessel has a deadweight of 3,350t and a cargo deck of 640m².

Gjøa floating production platform

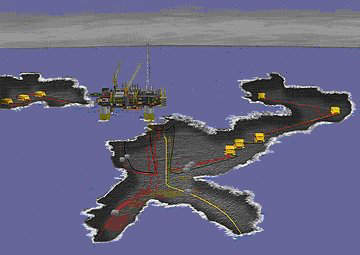

The Gjøa field will be developed with a floating production platform. The topside weight of the platform is 22,000t and the hull dry weight is 15,000t. The deck of the platform is 110m long and 85m wide.

The platform receives power from Statoil’s Mongstad facility near Bergen through a 100km subsea cable. This will help in reducing carbon emissions by approximately 250,000t per year.

In June 2010 the Gjøa platform installation was completed by Aker and towed to its location in the North Sea. The platform was then connected to various subsea installations and pipelines. In July 2010 Statoil turned on the power for the Gjøa platform.

Gjøa field development

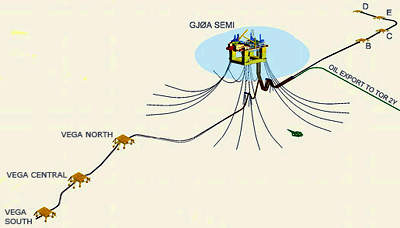

In mid-2007 the Norwegian Storting (parliament) approved the Gjøa Plan for Development and Operation (PDO). The project is economically marginal, but made viable through tying back the Hydro-operated Vega and Vega South fields to Gjøa.

StatoilHydro awarded a three-year $427m drilling contract to Transocean Offshore for 11 wells, with an option for a further three. The drilling of the first production well started in early 2009. The Transocean Searcher rig is drilling the wells at the field and will continue the drilling and completion activities until July 2012.

Gjøa exports

Gas will be sent via the UK Flags of 28in, 130km-long pipeline to St Fergus in Scotland. Oil will be piped through a 16in pipeline of about 55km length to the Troll II line and then to the Statoil-operated Mongstad refinery, which is located north of Bergen, Norway.

Gjøa contracts

Aker Kvaerner was awarded a contract for the construction and assembly of the platform deck in 2006. The contract was worth Nkr8bn. The scope of work included detail design of the topside and hull, procurement, construction and hook-up of the topside, and mating of the topside and hull. The platform was constructed at Aker Kvaerner Stord.

A Nkr450m living-quarters contract was awarded to Leirvik Module Technology. The design envisages 3,600m² of floor space. It was delivered to StatoilHydro on 6 May 2009. The quarters module will provide 100 single cabins with en-suite facilities, as well as offices, a control room, a canteen and lounges. It is built in aluminium to give a total weight of 1,650t, including the helideck and lifeboat station.

Samsung Heavy Industries was awarded the $150m contract to build the hull. Samsung commenced mobilisation activities with a planned fabrication start in South Korea in February 2008.

In 2008, IKM Gruppen was awarded a Nkr445m contract for main operations support for the Gjøa platform. The contract includes hiring 55 contractors for operating organisations and providing engineering services. The contract has tenure of five years with an option to extend for two more years.

In 2007 a contract for installing oil and gas export pipelines from the Gjøa field was awarded to Saipem. The company laid a 185km pipeline for oil and gas transportation.

ABB Power Technologies was awarded Nkr500m contract in 2007 to manufacture and install a 100km submarine cable from Mongstad, north of the platform.

In May 2009 SPT Group was awarded a contract to deliver the online Flow Assurance System (FAS) and associated services for the field for a period of five years, with a provision to extend it twice by three more years.

The Nkr500m worth installation and fabrication of the structures and tie-in of the pipeline systems contract was awarded to Technip Norge. The work began in 2009 with the final tie-in to the field in 2010.

StatoilHydro signed a contract with FMC Technologies in 2006 for the delivery of the subsea systems.