The $2.8bn Girassol project is located within Block 17, about 210km north-northwest of Luanda, Angola. It lies in 1,350m of water and was developed using a subsea facility tied back to a floating production, storage and offloading unit (FPSO).

Base-case reserves of the African field are approximately 630 million barrels of 32° API crude oil. The field came on-stream in December 2001. The average production from Girassol is approximately 240,000 barrels per day (bpd). The subsea production system comprises 39 wells, including 23 producers.

TotalEnergies (formerly Total) operates Block 17, with a 38% interest. Its partners in the block include Equinor (22.16%), ExxonMobil (19%), BP Exploration Angola (15.84%), and Sonangol P&P (5%). Sonangol gained interest in the block in 2019 under an agreement which allowed the consortium to extend all the production licences in Block 17 until 2045.

The development of approved satellite projects is expected to consolidate production in the Girassol, Dalia, Pazflor, and Rosa fields in the block.

Hull of the FPSO unit

The bare hull of the FPSO was built in the Hyundai Heavy Industries (HHI) shipyard in Korea and moved out of the dry dock in July 1999. It can store two million barrels of crude oil and support processes with a capacity of 200,000bpd.

It has an overall length of 300m, a moulded breadth of 59.5m, a moulded depth of 30.5m, and a design draught of 22.77m. The design life of the hull is 20 years without dry-docking.

Deadweight is 343,000t which includes 98% of cargo capacity and 50% of slop tanks.

The hull features a double-sided construction with 12 ballast wing tanks measuring 7m wide, as well as two fore-peak and two aft-peak ballast tanks. It has 12 cargo tanks in total.

Topsides and accommodation

The topsides contain living quarters, oil treatment facilities, storage, metering and offloading, gas treatment and re-injection facilities.

The integrated deck is 180m long and 60m wide, and weighs approximately 20,000t. The process deck is located 7m above the deck of the hull. It contains facilities for produced water treatment at a flow rate of 180,000bpd, as well as facilities for three million cubic metres per day gas lift, eight million m³/day gas compression at 285 bars, and gas dehydration.

The living quarters unit, located at the aft end of the hull, is designed to accommodate 140 people in 80 cabins.

Mooring, risers and umbilicals of the west African FPSO

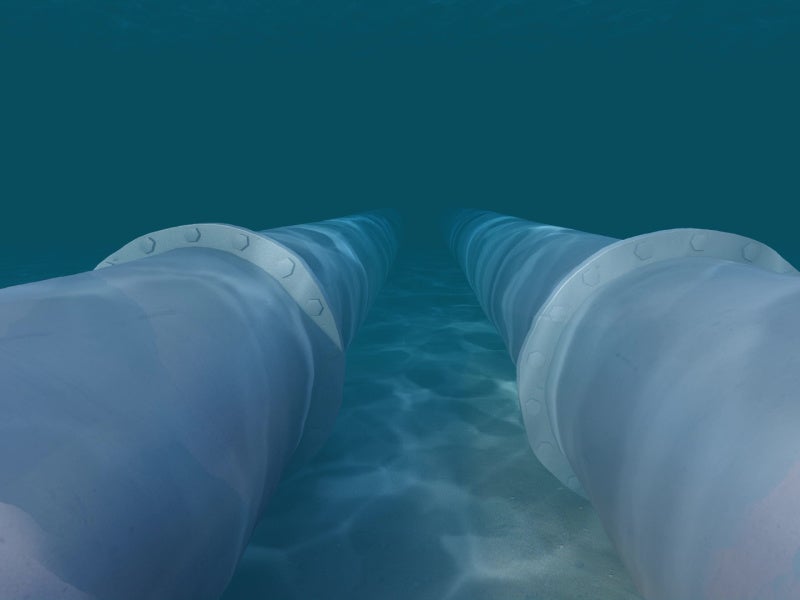

The FPSO was towed from Korea to Girassol, where the risers and umbilicals were installed and connected for commissioning and first oil.

The FPSO is spread-moored with 16 lines, four at each corner. The anchor lines are a composite assembly of chains and cables connected to 16 suction anchors.

The east side of the FPSO was designed to receive the umbilicals and risers from three riser towers. Each of the riser towers is connected to the FPSO by a riser, each of which is 1.5m in diameter and 1,250m long, said to be proportionately equivalent to a 1m length of piano wire.

Floats measuring 40m high and 8m in diameter are attached to the tops of the risers, along with flexible pipelines to carry the oil up into the FPSO. Each riser tower consists of 12 tubes arranged around a thick central pipe that acts as a backbone and the whole assembly is sheathed in epoxy insulating material.

In addition, ten umbilicals are connected to the base of the riser towers. The west side of the FPSO is designed to receive further risers and umbilicals if needed.

Offloading systems

The FPSO is designed for two off-loading systems, one for normal operation with a buoy and one as back-up off-loading, in tandem. Both systems are located at the bow of the FPSO.

The main off-loading system includes a loading buoy, located approximately one mile away from the bow of the FPSO. It can accommodate tankers from 80,000DWT to 400,000DWT, with a nominal off-loading rate of 6,000m³/h through two rigid steel catenary 16in lines.

The tandem off-loading structure is a conventional system with a mooring hawser assembly and handling system, and an off-loading hose and its handling system. It is designed to accommodate tankers up to 200,000DWT at a nominal off-loading rate of 8,000m³/hour.

Contractors involved

TechnipFMC, an energy technology provider based in the UK, was awarded a contract to provide flexible pipe and related hardware for a life extension project of the Girassol FPSO in February 2023.

The contractual scope includes engineering, procurement, and the supply of flowlines and connectors for the Girassol Life Extension (GIRLIFEX) project. The new flexible pipes will bypass the rigid pipe bundles to extend the field life. The rigid pipe bundles were installed before the start of production.

SPIE Oil & Gas Services, a subsidiary of European multi-technical services provider SPIE, was chosen to provide general maintenance services for the Girassol FPSO for five years, in July 2022.

FMC Technologies, now part of TechnipFMC, was awarded an $80m contract to provide a subsea production system for the GirRI (Girassol Resources Initiative) project, in January 2011. It supplied three subsea production trees, six wellheads and various flow-base and jumper systems as part of the contract.

TechnipFMC received the engineering, procurement, construction and commissioning contract (EPCC) for the second phase of the GirRI project in November 2012.

The main contractor, MAR Profundo Girassol, a joint venture (JV) between ETPM and Buoygues, was originally subcontracted to build the integrated deck at Fos-sur-Mer in France. It subsequently re-awarded the subcontract to Hyundai.

The riser towers were built by UK-based engineering company Acergy in Sonamet, Angola.

Saipem received a contract from TotalEnergies to provide engineering, procurement, fabrication, installation and commissioning of topside modifications for the GirRI (Girassol Resources Initiatives) project in Block 17 in October 2012.

Newrest Angola, a remote site management and catering services provider, secured a contract extension for the Girassol FPSO project in November 2020.