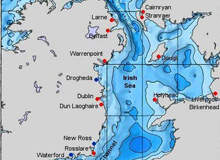

The Gateway Gas Storage Company (Gateway) is developing an underground natural gas storage facility, Gateway Gas Storage Facility (GGSF), 25km offshore south-west Barrow-in-Furness, UK, in the East Irish Sea.

The GGSF plant has a strong locational advantage for developing offshore salt cavern gas storage facilities, according to the British Geological Survey.

The facility will be linked to a new pipeline from the storage area to the shore, across Walney Island and the Piel Channel to a site near the North and South Morecambe gas terminals.

Gas will be stored in caverns to be developed in a natural salt structure below the seabed, allowing gas to be delivered, stored and then returned to the UK’s national transmission system.

On completion, the caverns will have a storage capacity of 1.5 billion cubic metres of gas (equivalent to 562 million therms).

Gateway appointed Stag Energy Development Company as the project manager for the development. A management services agreement was signed between the two companies.

Approval for developing the gas storage project was received from the UK Government in November 2008 and from Barrow Council in June 2008. The site licence agreement from the same was received in 2007.

In December 2010, Petrofac acquired a 20% interest in Gateway. Petrofac and Gateway will jointly develop the facility. The final investment decision on the project will be made in 2011. The first gas storage services from the project will start by 2016.

GGSF construction

Salt cavern technology is used for storing gas and liquids. GGSF will consist of 20 underground man-made storage caverns. The caverns will be mined by leaching into the salt strata below the Irish Sea. A small offshore structure will be installed above each cavern to provide areas for equipment such as motors, control systems and ancillary equipment for the leaching process.

A pipeline and isolation valve will join each cavern to a ring main, which will then be connected to the gas compression system (GCS) at Barrow-in-Furness by two pipelines and a power cable.

The offshore structures will be placed along with required control and monitoring equipment to minimise maintenance visits and intervention.

The GGSF will be linked to the national gas transmission system (NTS) through a new pipeline to a 300m x 200m gas compression station near the existing Morecambe gas terminals at Barrow-in-Furness.

The GCS will provide gas at a favourable pressure and flow rate for the caverns.

Equipment for the compressor system includes gas compression, dehydration, a vent stack, wastewater treatment, metering, fire security, a substation and a control room.

The bidirectional metering system will help export the exact quantity of gas to the NTS.

Electricity to the facility will be provided via a single 33Kv cable and a high voltage line of 66kV or 132kV. The 33kV cable will provide power to the compression system while the high voltage line will supply power to the offshore GGSF. Power will be provided via cable from the Roosecote Power Station.

Pipeline infrastructure

The Gateway Gas Storage project will have several pipelines. One 42in-diameter bidirectional import / export pipeline will be laid for the flow of gas to the NTS. Two 36in-diameter bidirectional pipelines will be laid for the inflow and outflow of gas from the caverns. These pipelines will link the offshore pipeline system with the compression system.

A 4in-diameter pipeline will provide methanol to wells within the offshore structure. The 36in bidirectional pipelines and methanol pipeline will be placed in a single trench.

During the gas import cycle, a specific volume of gas will be transferred from the NTS to the GCS via the metering system. During the export cycle, gas is sent back to the NTS from the caverns then back to the GCS through the export pipeline. The gas can be imported / exported either as a free flow or after compression (assisted import).

During times of sluggish demand for gas, supplies will be transferred from the NTS to be compressed and injected into caverns for offshore storage. During high demand, the pressure of gas to be transferred to the NTS will be adjusted and dried.

Gateway contracts

The front-end engineering design contract for the project was given to AMEC, Parsons Brinckerhoff and Senergy in January 2010. The scope of work consists of offshore installations, pipelines, the onshore compression station at the Morecambe terminals and connections to the National Grid.

The salt cavern design and construction will be carried out by Parsons Brinckerhoff. Senergy will be responsible for offshore infrastructure, installation, logistics and well designs.

Fugro Seacore was contracted to carry out site investigation for the project. The Environmental Impact Statement for the project was prepared by Rudall Blanchard Associates in 2007. Mesy-Solexperts carried out stress and permeability tests for the salt caverns.