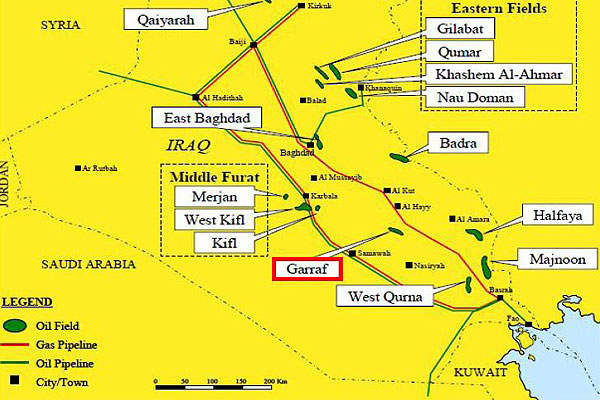

Garraf oil field is located in the province of Thi Qar, approximately 5km north-west of Al-Refaei city and 85km north of the city of Nasiriya.

The field is owned by PETRONAS Carigali Iraq Holding (PCIHBV, 45%), Japex (30%) and North Oil Company (25%).

Development work for the oil field started in early 2011 and initial production commenced in August 2013. The final development plan was approved by the Government of Iraq in 2018.

Although the development was scheduled for completion in late 2020, operations were suspended in March 2020 due to the Covid-19 pandemic. In July 2020, the field resumed operations at a production rate of 50,000 barrels of oil per day (bopd).

Japan Oil, Gas and Metals National Corporation (JOGMEC) provided financing to JAPEX for its participation in the project, in February 2011.

Garraf field geology, reserves and production

The onshore oil field was discovered in 1984 and contains oil in Cretaceous reservoirs. The field is 17.5km long and 5.5km wide. It is estimated to hold 1.3 billion barrels of oil reserves.

The production capacity of the field is expected to increase to 230,000bopd upon achieving full production.

Development of the Garraf oil field

The Development & Production Service Contract (DPSC) was awarded to a consortium comprising Petronas and Japex, under Iraq’s second bid round held at Baghdad in December 2009.

Drilling works on the oil field commenced in March 2011 using two rigs.

The development primarily involves the drilling of 150 wells. A total of 11 wells, including two appraisal and nine development wells, have been drilled to date.

Three of the completed wells were drilled by South Oil Company in the 1980s.

Facilities at the Garraf oil field

Construction of the initial surface facilities for production has been completed. Facilities include a degassing facility with two trains of 50,000 barrels a day each, eight storage tanks, piping, atmosphere (ATM) flares and other ancillary infrastructure.

Initial project activities involved the construction of a life support area capable of housing 600 people. The air-conditioned accommodation facilities were constructed using cold-formed steel.

Other works included the construction of pumping stations, access roads and spillways, fencing, HDPE piping and installation of approximately 1,533 helical piling to support the aboveground pipeline.

More than 2,188m³ of concrete was used to lay the foundations for the steel tanks.

Products from the oil field are transported through a 13km pipeline to the Gharraf-Badra tie-in area (GBTA). It is conveyed to the Nassiriyah storage depot via a 92km, 28-in pipeline, constructed by Petronas, which is a continuation of the pipeline being constructed for export from the Badra Oil Field by Gazprom.

Oil from the GBTA is conveyed to Al-Fao before being pumped to the country’s southern oil export terminals.

Contractors involved with the Garraf oil field development

Weatherford International was selected as the main contractor for the project and Lakeshore TolTest was appointed as the subcontractor. The front-end engineering and design study was carried out by Weatherford. The formworks for the initial production facilities were supplied by PERI.

The initial production facilities were constructed by LTC under a $70m subcontract awarded by Weatherford.

LTC carried out the engineering, procurement and construction (EPC) of the security walls at the oilfield, including the construction of temporary camp facilities for up to 50 people for six months.

The security walls were constructed using the company’s 60m³ per hour concrete batch plant located at the project site.

Unidro is providing design, fabrication, supply and start-up of a clarification unit for the field expansion project.

A consortium of China Petroleum Engineering and Construction Corporation (CPECC) and Progetti Europa & Global (PEG) was awarded a $308m engineering, procurement, construction and commissioning (EPCC) contract. The main scope of work includes the addition of oil train numbers 3, 4 and 5 for increasing the river water intake facility.

ERGIL was awarded a design, engineering, fabrication, and testing contract by CPECC.

UK-based Amarinth delivered four API 610 VS4 vertical pumps with Plan 53B seal support systems for train 5, under a $650,000 contract by CPECC.

Recon Technology signed a $2.8m engineering and construction service subcontract with Grand Energy Development Limited in May 2020.