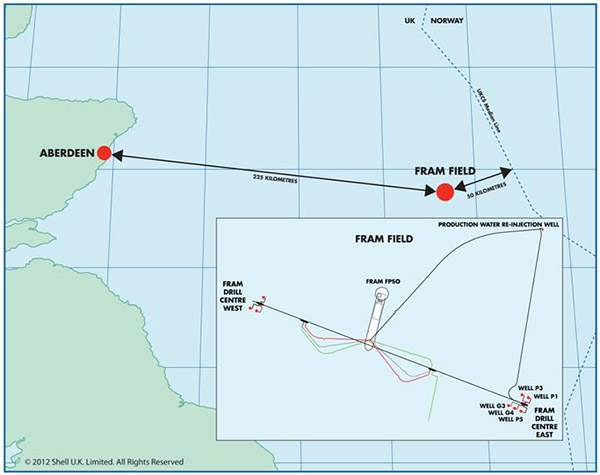

The Fram gas and gas condensate field is located in blocks 29/3c and 29/8a of production licence 012 (PL012) and blocks 29/4c and 29/9c of production licence 1664 (PL1664) of the central North Sea, UK.

It lies in 100m of water approximately 221km east of Aberdeen and 50km west of the UK and Norway median line.

The field is being developed by a joint venture between the operator Shell UK (32% equity) and Esso Exploration and Production UK (68% equity). The Department of Energy and Climate Change (DECC) originally approved the development of the field in September 2012.

A drilling campaign for the project was carried between 2012 and 2013, which resulted in unexpected reservoir results that led to the suspension and subsequent re-evaluation of the project development concept.

The final investment decision (FID) on the project was taken in June 2018. The first production from the field occurred in 2020. The field is expected to have a life of approximately seven years.

The development of the field increased the UK’s daily oil production by 2% and provided an alternative source for the UK North Sea’s declining oil and gas resources.

North Sea-based field discovery and reserves

Shell and Esso’s joint venture (JV) discovered Fram during the drilling of the 29/3-1 exploration well in 1969.

The well encountered an oil rim with a gas cap inside a Palaeocene age Forties reservoir in a four-way dip closure around a salt diaper structure.

Development of the field was, however, considered unfeasible due to the complex structure of the reservoir, in addition to the small volume of hydrocarbons and non-availability of processing and export facilities close to the field.

The Fram field is estimated to hold around 390 million barrels of hydrocarbons in place. It is expected to produce about 41 million standard cubic feet of gas per day and 5,300 barrels of condensate per day, totalling 12,400 barrels of oil equivalent per day, at peak production.

Fram gas and gas condensate field appraisal

The full potential of the site was only discerned after the drilling of another appraisal well, 29/3a-6, almost 40 years after the discovery of the field.

A series of 3D seismic surveys and studies were carried out between 2007 and 2008 to analyse and understand the field reservoir. The studies provided a better understanding of the complex structures of the field.

A pair of new appraisal wells, 29/3c-8 and 29/3c-8z, were drilled in the first quarter of 2009 by the Sedco 711 semi-submersible rig, to identify an optimum solution for the development of the field.

After a series of drilling and testing operations in 2009, significant recoverable amounts of hydrocarbons were found, thereby establishing the feasibility of the field.

A re-appraisal was conducted and the field was approved for development as a gas and gas condensate field.

Fram gas and gas condensate field development plan

The Fram field development involved the drilling of two new horizontal wells, G3 and G5, using a semi-sub drilling rig in the drill centre east (DCE) area.

The first well, G3 (29/3C-A3), is a continuation of an existing well, while the second well (G5) is located 30m away from the G3.

A new Fram manifold located 500m away from the area connected the two wells.

Fishing-friendly structures protect the wellheads and trees, thus reducing the risk of snagging.

Hydrocarbons produced from the site are sent via a new 10in/16in surface-laid pipe-in-pipe production flowline to the existing Starling subsea manifold, which is located approximately 15.2km from the wells.

The Starling and Fram manifolds are connected via a control umbilical trenched at a depth of 0.6m.

The produced hydrocarbons are transported from the Starling manifold using existing infrastructure to the Shearwater complex located at 33km for processing.

Fluids processed at the Shearwater complex are exported onshore via the Shearwater Elgin area line and the Forties pipeline network.

The master control system of the Shearwater complex was modified to serve the present and future subsea field developments while the chemical injection system was tuned for the addition of a low-dose hydrate inhibition (LDHI) system.

Contractors involved

Shell awarded a $135m contract to Subsea7 in January 2013 for the engineering, procurement, fabrication and installation of a 4.5km-long and 44in-diameter pipe bundle with manifolds and tie-ins.