The Ettrick field is located in the Outer Moray Firth, 120km north-east of Aberdeen in blocks 20/2a and 20/3a in the UK sector of the North Sea. The field is operated by Nexen with an 80% working interest, Bow Valley Energy (a subsidiary of Dana Petroleum) with 12% and Atlantic Petroleum with 8%.

Discovered in 1981, Ettrick was appraised by seven wells between 1982 and 1985. The reservoir at the field mainly lies within the upper Jurassic Ettrick sandstones, while the Zechstein reservoirs lie in the Jarvis structure.

Bow Valley was acquired by Dana Petroleum in April 2009. Following the acquisition, production from Ettrick was to be increased by commissioning a gas system.

Ettrick production

Although production was to start in 2008, it was delayed because of delivery problems of the leased FPSO due to the unavailability of third-party labour at the Singapore construction yard.

Ettrick’s first oil was produced in August 2009. The production rate was maintained at 30,000boe per day to test the design capacity of the FPSO.

The initial production was restrained by gas compression in order to optimise the field’s future production of 20,000bpd. Production was increased to full capacity in 2010.

Ettrick field development

The Ettrick field development, which includes three subsea production wells and one water injector to be tied to the FPSO, was authorised by the UK Government in July 2006.

The first well was drilled by a Borgsten Dolphin semi-submersible drilling rig at a water depth of 366ft in March 2007. It penetrated to a depth of 12,240ft and touched the upper Jurassic sandstone reservoir. Production was suspended while two wells and one water injector were drilled. A total of six wells were drilled between March 2007 and March 2009.

Aoka Mizu FPSO

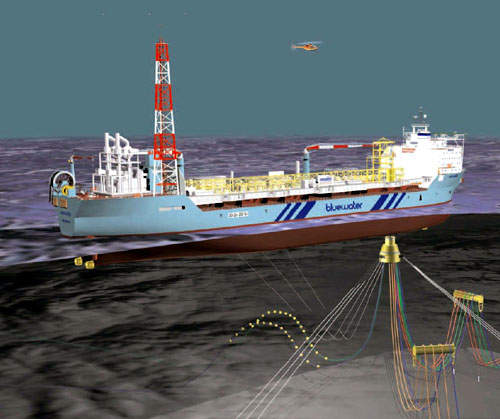

Bluewater won the contract for Ettrick’s production facilities and operations. Bluewater designed, supplied and operates the FPSO, including topsides and a disconnectable turret mooring system. The FPSO has a capacity to handle 30,000bpd and 35mcf per day of gas. Its capacity to re-inject 55,000 barrels of water per second was deployed in August 2009.

The FPSO is based on the newly built, Aframax-size FPSO hull Aoka Mizu, which went through an extensive conversion programme for the project.

The Aoka Mizu is 248.12m long, has a 42m moulded breadth and a 21.2m moulded depth. It has a 14.9m design draft and a deadweight of 105,000dwt. The vessel has a 7,985m2 deck area, a 6,000m2 topsides and a 8,000t deck payload.

In July 2010, AMEC was awarded a contract to provide engineering and maintenance services to the Aoka Mizu FPSO for two years.

Drilling at Ettrick

Drilling was planned in two phases. Under phase I, three production wells – P1, P2 and P3 – were drilled, along with the first water injection well, and were tied back to the project’s FPSO through two infield flowlines and flexible risers.

The contract for installing and connecting subsea pipelines, umbilicals, risers and structures for the field was given to Sonsub. The flexible risers and umbilical were installed by Sonsub in 2008.

Ettrick processing plant

Ettrick’s processing plant has a 35,000bpd fluid capacity and a 30,000bpd crude production capacity. It has an 18mcf per day gas-lift facility. Treated seawater for injection into the reservoir was mixed with produced water at a rate of 55,000bpd.

Under phase II, a second water injection well, I2, was drilled. Drilling activities over the field continued throughout 2010.

In April 2006, NKT won the contract to provide a flexible package including 12 flexible risers and flowlines for the project.

Gas can be exported at 20 million cubic feet a day through a subsea pipeline system. It can offload oil at 5,200m3 per hour in volumes of 500,000 barrels to tandem moored shuttle tankers. The FPSO has crude storage capacities of 95,000m3 (600,000 barrels.

There are also 7,150m3 (45,000 barrels) slop tanks and 2,982m3 (18,000 barrels) of fuel oil.

The vessel has Lloyd’s Register of Shipping – Class Notation +100AT, an oil barge with descriptive notations Pt higher tensile steel, increased scantlings for longitudinal strength, and fatigue for FPSO service in harsh environments, including Norwegian, Canadian and West of Shetland waters.