The Elk Creek pipeline is a proposed natural gas liquids (NGLs) pipeline between eastern Montana and Rice County in Kansas, US. The project is being developed by ONEOK with an estimated investment of $1.4bn.

ONEOK announced plans to develop the new pipeline and associated facilities in January 2018. The project is currently in the planning stage, while construction work is expected to start in late-2018. The land acquisition process for the pipeline commenced in February 2018.

Completion of Powder River Basin, the mid-continent portion of the pipeline, is scheduled for the third quarter 2019. The entire project is anticipated to be completed by the end of 2019.

The pipeline is intended to transport unfractionated NGLs from the Rocky Mountain region to ONEOK’s mid-continent NGLs infrastructure. It is expected to help reduce natural gas flaring by providing a cost-effective means of transportation.

The Elk Creek natural gas pipeline project is part of ONEOK’s $3.5bn capital-growth projects, which include the 400,000bpd Arbuckle II Pipeline, the 125,000bpd MB-4 NGL fractionator, and the 200Mmcf/d Demicks Lake natural gas processing plant and associated infrastructure.

Elk Creek natural gas liquids pipeline design and route details

The proposed Elk Creek pipeline will be approximately 900-miles (1,448.4km) long and have a diameter of 20in. It will have an initial capacity of approximately 240,000bpd of NGLs, which will be expandable up to 400,000bpd with additional pump facilities planned in the future.

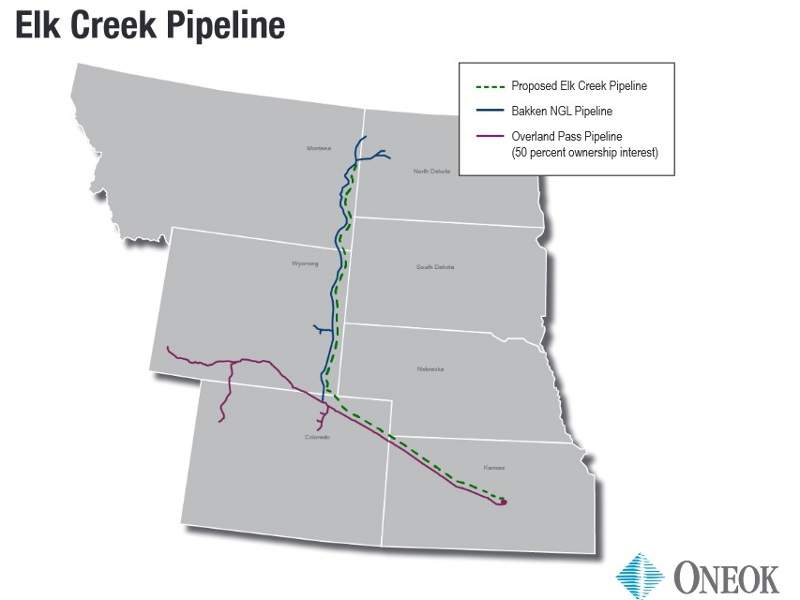

The pipeline will originate in Richland County near Sidney, Montana, and pass through eastern Montana, Wyoming, and then traverse northeast Colorado before terminating in Bushton, Rice County, Kansas.

The proposed pipeline will be laid parallel to the company’s existing Bakken NGL pipeline and Overland Pass pipeline, which are operating at full capacity.

Elk Creek pipeline construction

High-strength steel will be used to manufacture the Elk Creek pipeline. The right-of-way for the pipeline will be cleared and graded after staking the pipeline route. The pipe sections will then be laid along the right-of-way and will be buried at a depth of approximately 3ft below ground, in compliance with the US Department of Transportation pipeline safety regulations.

The joints will be bent and welded together to form a continuous segment. The pipeline will be inspected using X-rays to verify its integrity. A protective layer of coating will be applied to prevent corrosion of the pipeline, which will then be lowered into the trench and backfilled with subsoil.

The operating pressure of the pipeline will be tested and validated with water under the federal pipeline safety regulation.

Financing

ONEOK plans to invest roughly $1.2bn for the construction of the Elk Creek natural gas liquids pipeline, while the related natural gas infrastructure is estimated to cost up to $200m.

The project will be financed with cash generated from ONEOK’s operations including approximately $450m of net proceeds raised by issuing common stock in 2017 under the company’s at-the-market equity programme.

Benefits of Elk Creek pipeline

The project will strengthen ONEOK’s NGL network in the Bakken, Powder River and Denver-Julesburg regions and provide increased pipeline capacity to meet the growing NGLs production in the region.

It will also allow the company to ensure safe and reliable NGL supply from the Canadian border to the growing markets in the Texas Gulf Coast.