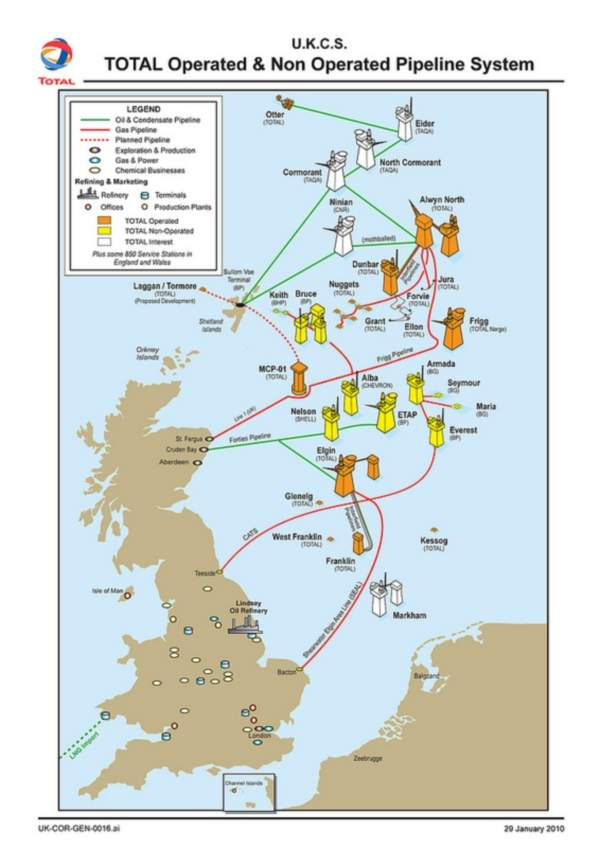

Elgin and Franklin lie 93m deep in the water the UK North Sea’s Central Graben, approximately 240km east of Aberdeen. Elgin is located in blocks 22/30b, 22/30c and 29/5b. Franklin is located approximately six kilometres south-east of Elgin and lies within block 29/5b. Elgin was discovered by Elf in 1991, with the well 22/30c-8. Franklin was discovered by Ultramar, in 1986, by well 29/5b-4 and was appraised by wells 29/5b-6 and 29/5b-8.

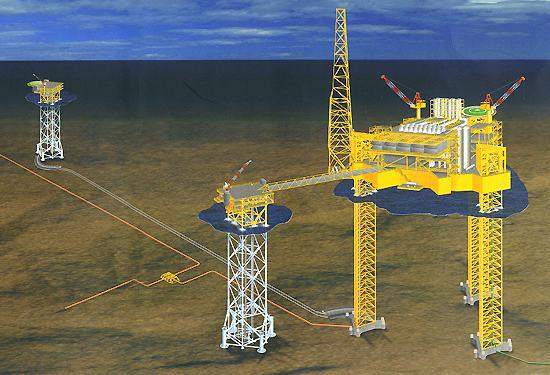

As the two fields are adjacent to the joint development of their reserves was a good option. In 1995, the project partners reached agreement on a development plan comprising two wellhead platforms – one on each field – tied into a shared processing and export platform.

Total’s 100% subsidiary EFOG operates the field by holding the largest stake of 46.2%. The other stakeholders are ENI 21.8%, BG 14.1%, E.ON Ruhrgas 5.2%, Esso Exploration & Production 4.4%, Chevron 3.9%, Dyas 2.2% and Summit Petroleum 2.2%. Total’s share increased from 35.8% to 46.2% when it acquired GDF Suez’s interest in the two fields for €590m in December 2011.

Elgin-Franklin offshore reserves

Reserves are estimated to be approximately 60 million cubic metres of condensate and 50 billion cubic metres of gas. The first production from these two adjacent gas fields was brought on-stream in March 2000 and this is expected to continue until 2022.

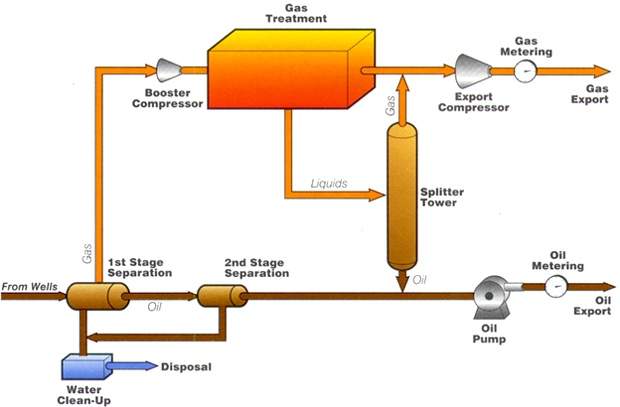

The sour condensate gas, which has an average carbon dioxide content of 3.5% and up to 40ppm of hydrogen sulphide, required purpose-designed equipment and an innovative development plan, under which commercial gas would be produced on an offshore processing platform.

Largest high-pressure / high-temperature development

Elgin-Franklin is the world’s largest high-pressure / high-temperature (HP / HT) development. Due to the extreme reservoir conditions – an initial pressure of approximately 1,100bar and temperatures of 190°C and complex geological structures – the fields pose a considerable development challenge.

Brought on-stream in 2001, by March 2002 the fields achieved peak production of 140,000 barrels of condensate and 485 million cubic feet of gas a day.

In 2003, a new, record-breaking well was developed from the Elgin-Franklin platform to the West Franklin reservoir, which is the hottest, highest-pressure reservoir in the world. The well was drilled to a depth of 6,100m and stepped out 1.5km to tap an accumulation with a temperature of 197°C and a pressure of 1,155bar.

Wellhead platforms at Total’s Elgin offshore gas field

The field is controlled by normally unmanned wellhead platforms on Elgin and Franklin, which are connected to and remotely controlled from a single production / utilities / quarters (PUQ) platform on Elgin.

The Elgin wellhead platform consists of 1,743t topsides and a 2,715t, four-leg steel jacket containing 12 platform slots. The Franklin platform consists of a 2,800t jacket supporting 2,093t topsides. It contains nine platform slots.

The jackets supporting the topsides were constructed at Stornoway and transported, by barge, to their offshore sites, where they were positioned in and piled into the seabed. Santa Fe’s drilling rigs Galaxy 1 and Magellan continued the drilling programme through the jackets until the topsides were lifted into place. The rigs drilled five production wells (and reconnected two existing appraisal wells) on Elgin, then drilled five production wells on Franklin. The drilling programme took 2,883 days.

So far Total invested more than £1.65bn (€2.8bn), in the two fields, including €33m for R&D. At peak production, the fields were turning out approximately 220,000 barrels of oil equivalent a day, or approximately 7% of total UK production.

Production / utilities / quarters (PUQ) platform

The wellhead platforms were connected to an integrated, permanently manned PUQ platform on Elgin. The Elgin drilling platform is linked by a 100m access bridge (along which hydrocarbons will be piped), while the Franklin platform is connected via an inter-field pipeline system.

The PUQ platform is of a jack-up-style TPG 500 design, conceived by Technip Geoproduction. This was chosen in preference to a conventional fixed production platform, because it could be built onshore as one complete unit, reducing the need for heavy lifts offshore. The majority of the hook-up and commissioning work was carried out onshore before sail away.

The contract for the fabrication, installation, hook-up and commissioning was won by a consortium of three companies – Technip UK Limited, McDermott Marine Construction Limited and BARMAC.

The TPG 500 was towed out to the Elgin field and manoeuvred into position, where its legs were lowered. On contact with the seabed, its 24,500t deck was jacked-up by 34m.

Hydrocarbon exportation and liquids pipeline

To transport the liquids via the Forties System, a new 24in-diameter spur line, called the Southern Spur, was constructed, running from the PUQ to a subsea connection close to BP’s Marnock platform. Liquids from the nearby Shell-operated Shearwater platform are also transported through this spur line, via the Shearwater Spur, tied in at a ‘T’ piece, about two kilometres north of the Elgin PUQ.

Elf was the operator throughout the design, construction and pre-commissioning phases, but BP now operates the Southern Spur, and Shell the Shearwater Spur.

Gas export pipeline – Shearwater Elgin area line (SEAL)

A new 34in-diameter 468km-long pipeline – the SEAL pipeline – exports the commercial-quality gas from the Elgin-Franklin development and Shell’s Shearwater development to the SEAL terminal in Bacton, Norfolk (operated by Shell). The pipeline originates at the Shearwater platform, with the Elgin-Franklin development also tied in with a subsea ‘T’ connection.

From there, the gas is routed one of two ways – either through a 450m, 24in pipeline to the Transco Terminal, or through a 900m, 34in pipeline called SILK (SEAL Interconnector LinK) and operated by Total E&P UK to the Interconnector terminal.

Although the gas produced from Elgin-Franklin and Shearwater is processed offshore to meet sales gas specifications, the new facilities at Bacton adjust the temperature and pressure of the gas and meter its delivery to the Transco and Interconnector terminals.

From the Transco terminal, it is sent to the UK’s National Grid, and from the Interconnector terminal, it is sent to Europe (Belgium).

Proposed future developments at the North Sea field

In 1999 Total E&P UK discovered the Glenelg accumulation in Block 29/4d, located just four kilometres west-south-west of the Elgin PUQ platform. Development of this discovery was being worked on even before Elgin-Franklin started production.

Glenelg has difficult geology in that it is a tilted fault block structure. The reservoir lies around six kilometres below the seabed, where the pressure is 1,100bar and the temperature is 200°C, which is similar to Elgin-Franklin.

The exploration well, 29/4d-4, was drilled by the heavy-duty jack-up rig, Transocean Nordic, in 1998/99. Oil and gas were encountered in the Upper Jurassic Fulmar sandstones below a depth of 5,400m with initial tests indicating a daily flow rate of 0.65 standard cubic metres of gas and 2,100 barrels of condensate. The first production from Glenelg was brought on-stream in March 2006.

In October 2007, production started from the F7 well of West Franklin. The F9 of West Franklin well was spudded in June 2007 and production started in August 2008, boosting reserves to 200,000 barrels of oil equivalent.

The company also drilled Franklin Infill Well in 2007 and demonstrated the potential to drill infill wells into depleted HP/HT reservoirs. This technological advancement paves the way for future phased development of HP / HT fields. West Franklin Phase II development, including three additional wells and a new platform, was approved in November 2010. The production is expected to start by the end of 2013.

By 2010, two infill wells were drilled on the Elgin field, also known as EIA. The company completed extended well test on Kessog discovery appraisal well 30/1c-9 in 2009.