The Deep Panuke gas field is located 250km south east of Halifax, Nova Scotia, Canada. Encana Corporation (formerly PanCanadian) has a 100% interest in the development.

The wells tap into the natural gas reservoirs in the carbonate reef located underneath the original Cohasset-Panuke oilfield – Canada’s first offshore project – which ceased production in late 1999. The life of the field is estimated to be between eight and 18 years. The first gas from the field is expected in the first quarter of 2012 with an initial production rate of 200mmcf/d.

Development of Deep Panuke

The area was first explored by Shell in 1986 and in the 1990s by Encana. Since 1999, the operator has drilled four wells into the Deep Panuke structure, 3,400-3,500m below the now depleted Panuke oilfield. The PP-C3 well discovered 225ft of net pay, producing at a rate of 55 million cubic feet of gas per day.

The first appraisal well, PI-1 b, showed 110ft of net pay, while the second appraisal well, H-08, flowed at an average rate of more than 50 million cubic feet per day of natural gas – the maximum capacity of the testing equipment – during a three-day test. The third appraisal well, M-79A, was drilled offshore about 3km east of the Panuke platform. The horizontal sidetrack encountered 360ft of net pay.

The natural gas project was given the go ahead in February 2001 when the billion dollar project to deliver 400mmcf per day natural gas from reserves of approximately one trillion cubic feet received approval.

The operator awarded the contract for the front-end engineering design (FEED) study for the project to the Accent-Saipem Energy Joint Venture.

The project was shelved and a new plan was prepared in 2006. The new plan was approved in 2007. By July 2010 installation of the subsea trees at each of the wells drilled at the field was completed.

Geology of Deep Panuke

A keynote of the Deep Panuke geology is its position at the reef margin. The field reservoir formed in late to middle Jurassic age and is made of limestone and dolomite.

The Rowan Gorilla III rig

The Rowan Gorilla III jackup drilling rig is owned by Rowan. It was built by Marathon LeTourneau at the Vicksburg, MS shipyard. The rig can operate in water depths of 450ft and drill up to 30,000ft.

The rig was towed to the gas field in January 2010. In March 2010 the Rowan Gorilla drilled one acid gas injection well. The well will be used for safe disposal of hydrogen sulphide and carbon dioxide removed from the natural gas that is produced at the field. The rig also completed drilling of two production wells by July 2010. Work on the remaining two wells is ongoing.

SBM Production Field Centre (PFC)

Gas will be produced by a jack-up type Production Field Centre (PFC), which will have a capacity of 300mmscfd. It will include facilities for separation, compression, gas processing, condensate stabilisation and water treatment. The hull of the PFC includes jacking systems, foundations, accommodation for 75 people, helideck and other utilities.

As of January 2012, subsea installation and hook-up of the PFC is ongoing. The PFC was transported to the field on BOA’s barge BOABARGE 36.

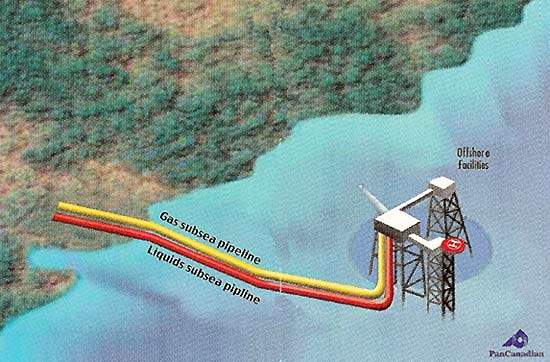

Pipeline route

Deep Panuke will require its own subsea pipeline because the Sable Offshore Pipeline does not have sufficient capacity to carry extra reserves.

The 176km pipeline will transport the gas produced from the field to Goldboro where it will connect with Maritimes & Northeast Pipeline (MNP) main line.

MNP’s 1,051km pipeline crosses the Canada / US border into New Brunswick and terminates in Dracut, Massachusetts.

Deep Panuke contracts

In February 2008 Acergy was awarded a $195m engineering, procurement and construction contract for installation of 17km of flowlines and umbilicals. The subsea equipment will connect the production wells to the FPSO. Acergy is using its construction vessels Acergy Falcon and Acergy Discovery to carry out the pipeline installation works.

Acergy subcontracted CRC-Evans/Global Pipelines to carry out onshore double jointing and offshore welding of the production lines.

Claxton Engineering Services, a unit of Aceton, was awarded a $1.9m contract for supplying and installing a 5,000psi riser system at the field. The riser system includes 24in diameter riser joints, connectors, umbilicals and a power unit. 2H Offshore, another unit of Aceton, provided riser analysis for the project.

Dominion Diving carried out Multi Beam and ROV surveys for placement of the PFC at the field.

Under a $14.4m contract, Tideway carried out stone filling on the seabed to stabilise the PFC and protect the pipelines from the high waves and strong seabed currents. Tideway used a new Inclined Fallpipe System and its Tideway Rollingstone vessel for the filling.

M&A Engineering was contracted to supply specialised pipe machining equipment for the field. McNally International carried out marine and onshore works for the shore access of the project. It subcontracted Bezemer to supply 500mt beach pull for the project.