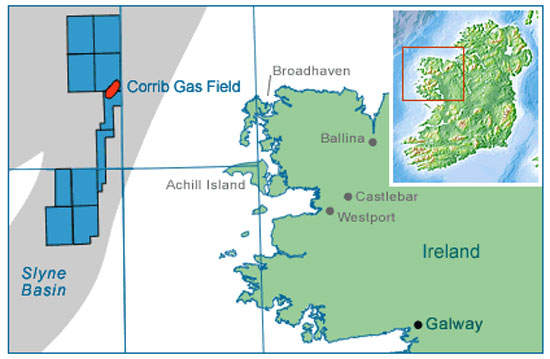

The Corrib field is a Triassic gas development in the Atlantic Ocean, situated off the coast of Ireland. It is approximately 50 miles west of the Mullet peninsula in County Mayo and lies in the Slyne Trough in Blocks 18/20 and 18/25. The Corrib gas field was discovered in 1996 and represents the first commercial find offshore Ireland, since Kinsale Head in 1973.

The gas field came online in December 2015 and is anticipated to produce approximately 260MMscf/d (million standard cubic feet per day) of gas.

Equity

The Corrib co-owners are Shell E&P Ireland (operator, 45%), Statoil Exploration Ireland (36.5%), and Vermilion Energy Ireland (18.5%).

The water depth in the area is 355m and the gas reservoir is located 11,500ft to 13,000ft below the seabed. Development costs are estimated at around £500m. The hydrocarbons will be produced over a period of between 15 and 20 years. The Corrib gas is H2S-free and exhibits an expected condensate yield of less than 0.5bbls/mmscf, 0.3% CO₂.

Drilling

Eix wells have been drilled at the gas field. Enterprise used the Sedco 711 drilling rig for appraisal and production drilling. Tests have confirmed a flow rate of 60 million cubic feet a day. Reserves in the field are around one trillion cubic feet, or about 70% the volume of the Kinsale field.

Development

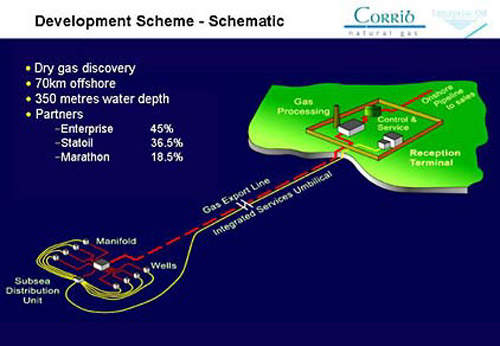

The development concept for Corrib comprises subsea wells, tied back to a central gathering manifold, connected to an offshore pipeline. The 20in pipeline carries gas back to a landfall point and then a short distance onshore to the Bellanaboy Bridge gas processing terminal located in County Mayo.

The County Galway port of Rossaveal was examined as an oil and gas exploration service base. In May 2008, Shell E&P Ireland Limited (SEPIL) confirmed that applications for consent to modify the Corrib onshore pipeline route were submitted to the Department of Communications, Energy and Natural Resources under the Gas Act.

The Ocean Guardian drill rig owned by Diamond Offshore Drilling was used for carrying out drilling activities at the field.

Pipeline landfall

For the pipeline landfall, a trench has been excavated in the seabed from the high water level to approximately 10m below the lowest tide. Following this, a pipeline was strung onshore and pulled offshore through the trench or the lengths of pipeline were welded together offshore and pulled onshore. After this, the landfall section was welded to the offshore pipeline on the lay barge. The control and chemical injection umbilical was installed alongside.

Processing

The gas passes through the slug catcher in order to remove the bulk of the liquid. Following that, the gas is then compressed and metered. Condensate produced in the gas, as well as that separated from the feed gas in the slug catcher / inlet separator, is routed to the condensate stabilisation system. This is essentially a two-stage flash system with intermediate heating. The stabilised condensate is cooled in an air cooler and sent to storage.

Methanol recovered from the slug catcher is fed through a particulate filter into the flash drum and onto the raw methanol storage tanks. It is then pumped to the methanol still via the still feed / bottoms exchanger. The column overhead vapour product is condensed in forced draught air coolers and flows to the product methanol storage tanks.

Water produced from the Corrib field contains small amounts of naturally occurring dissolved salts and trace elements and small volumes of liquid hydrocarbons. The water is comprehensively treated in the terminal to ensure that the levels of trace elements discharged into Broadhaven Bay will be so low as to have no discernible impact on background levels in the Bay.

Key players involved with the Corrib Gas Field development

ABB won a $30m order to deliver the subsea production system. Under the terms of the contract, ABB was responsible for the engineering, procurement, fabrication and testing of the subsea and associated shore-based equipment.

ABB’s involvement included project management, engineering and the supply of the manifold and protection structures, control system, subsea trees, diverless tie-in equipment, intervention equipment, integration testing and installation support.

Allseas Construction was responsible for the design, procurement, fabrication, welding of HDPE lines, pipe laying, survey and logistics of

Corrib pipeline and umbilical system

Technip was contracted for the project management services and the installation of umbilical, a 20in spool piece and three flexible flow-lines.

Ocean Installer received a contract for the survey of 20in pipeline and boulder relocation using the Normand Clipper construction support vessel (CSV).

RSK received a contract from Shell E&P Ireland to offer an environmental survey plan for Corrib offshore gas field.