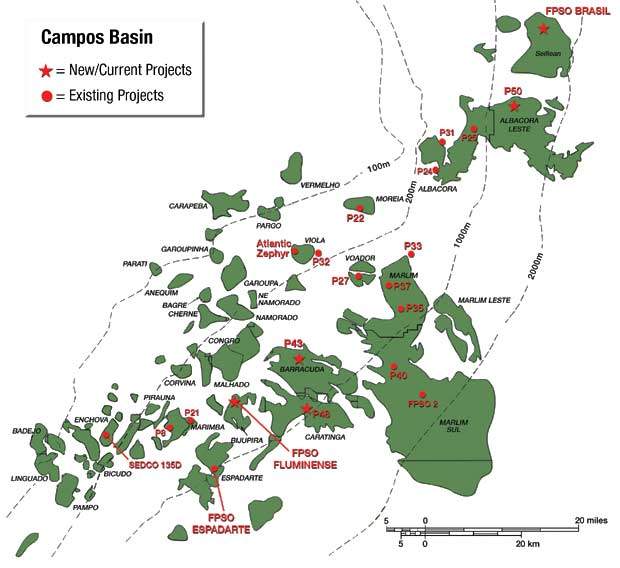

Bijupira and Salema are located 250km east of Rio de Janeiro. The fields are operated by Enterprise (55%) on behalf of Odebrecht (25%) and Petrobras (20%). They range in water depths between 1,575ft and 2,900ft.

The fields have combined estimated recoverable reserves of around 170 million barrels of oil in place. Bijupira is the larger with 114 million barrels. The Bijupira and Salema crude oils are relatively light (28° API and 31° API, respectively). There is also 1.6 billion cubic metres of gas.

The fields were discovered by Petrobras in 1990. The reservoirs lie at around 2,900m below the seabed in an Eocene age sandstone reservoir of the Carapebus formation. They have three producing zones.

EARLY PRODUCTION

The discovery well was followed by 13 delineation wells. In an early production scheme between 1993 and 2000, two Bijupira wells and one Salema well were tied back to the P13 semisubmersible to produce 25 million barrels of oil – 80% of this from Bijupira. Gas was exported via pipeline to the P15 gas gathering platform.

DRILLING PROGRAMME

Enterprise awarded the $55 million development drilling contract to Diamond Offshore Drilling. This is being conducted using the semi-submersible drill rig, Ocean Yorktown, with 16 wells provisionally planned. The contract commenced mid-2001. Key contracts include Dril-Quip supplying wellheads and subsea trees, Baker Hughes Inteq for measurement, logging and cementing services and Schlumberger for well testing. Halliburton will complete the wells.

DEVELOPMENT

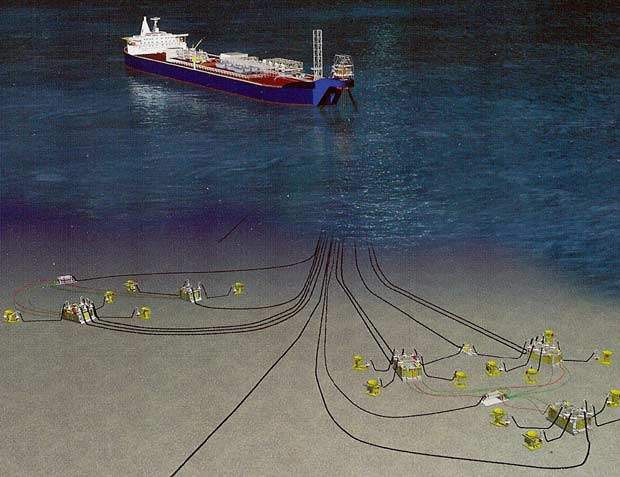

The designers settled on a ship-shaped Floating Production Storage and Offloading system (FPSO) as the preferred development option. A joint venture of FMC Technologies and MODEC International signed a $290 million contract with Enterprise to provide the vessel and related subsea equipment.

The FPSO will receive hydrocarbons from the subsea wells, gathered around two centres on the seabed some 5km apart. Bijupira will have two production and one water injection manifold in 770m of water. Salema, however, will have one production and one water injection manifold in 620m of water. The manifolds, weighing in at around 110t each, will be fabricated by FMC’s subsidiary in Brazil, CBV, based in Rio.

Bijupira’s manifolds will be connected to the FPSO through four 8in diameter flexible production flowlines and risers and an 8in water injection line. For Salema, two 6in production flowlines and risers and a 4½in water injection line will be used. Gas lift lines will be 4in and 5in diameter.

FLOWLINES AND RISERS

MODEC International will supply the Fluminense FPSO vessel, flowlines and risers. The contract includes 13 years of operations which will also be managed by MODEC. FMC will supply a turret mooring system and five subsea manifolds at a combined value of $56 million. The turret will have space for 15 risers and three umbilicals and there will be two spare slots. The FPSO will be secured to the seabed by nine mooring lines, giving the vessel the ability to weathervane. Gas will be transported through an existing 10in line to P15.

Artificial lift will be required to raise the reservoir fluids to the surface for processing. Reservoir pressure will be maintained by the high-pressure injection of seawater. In total, the development envisages six horizontal producing wells in Bijupira along with four water injectors and a further three horizontal producers and two injectors in Salema. Gas lift will also be employed.

FPSO

The Fluminense is being converted from the Sahara, a 27-year old crude oil tanker, at the Jurong shipyard in Singapore. The 362m long, 354,000t Fluminense, will then be moored in 700m of water. Onboard, it will have an oil processing capacity of 70,000 barrels of oil per day, a gas handling capacity of 75 million cubic feet per day and the ability to inject 92,000 barrels of water per day. It will have a storage capacity of 1.2 million barrels. The fields will produce at a rate 70,000b/d of light crude oil and 2 million m³/d of gas.