The Big Foot oil field is situated on the Walker Ridge block, 29, 362km south of New Orleans in the Gulf of Mexico, US.

Located at a water depth of more than 1,500m, the field is considered to be the eighth biggest deepwater oil field in the Gulf of Mexico. It is estimated to hold oil and gas reserves of more than 100Mboe.

Chevron is the operator of the field with a 60% share, while Statoil (27.5%) and Marubeni Oil & Gas (12.5%) hold the remaining stakes.

The Big Foot oil field received a $4bn investment and came on stream in November 2018. The project was sanctioned by Chevron in December 2010 and construction works commenced in 2011.

It is expected to have a production life of 35 years.

Big Foot oil field discovery

Big Foot was discovered by Chevron in 2006 by the Big Foot No. 2 well. The well was drilled by the Cajun Express semi-submersible rig to a depth of 1,524m. It encountered more than 91m of net oil pay.

Drilling and exploration

Three appraisal and exploration wells were drilled at the field, including the discovery well. The wells were drilled with several sidetracks to define the structure of the field reservoir.

Chevron completed the drilling of appraisal well Big Foot No 2, sidetrack No. 3 in 2007. The well was drilled by an ENSCO 7500 semi-submersible rig to a depth of 7,447m.

Another appraisal well called Big Foot No 3, Sidetrack No 2, was drilled to a depth of 7,654m in January 2008.

Development of Big Foot

Initial development plans for the field included seven production wells and three injection wells. The wells were drilled from the floating drilling and production facility.

Floating, drilling and production facility

Chevron developed the Big Foot field using a dry-tree floating, drilling and production facility.

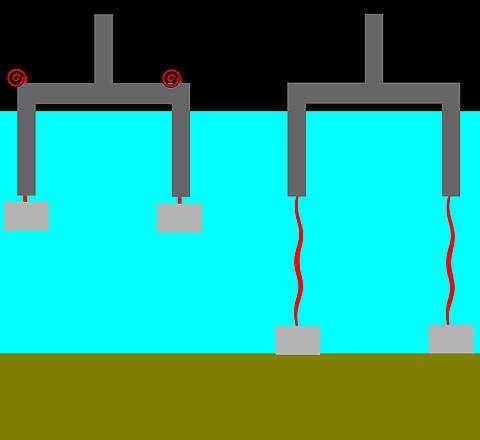

The hull is an extended tension leg platform (ETLP) moored in 1,615m of water. It features various oil and gas processing systems including gas compression, oil and water treatment, and export and utility systems.

The facility has production and drilling capabilities and accommodation facilities for on-board personnel. It is designed to export oil to a pipeline or a floating storage and offloading vessel.

Big Foot ETLP

The ETLP operating for the Big Foot field features dry trees and top-tensioned risers. It has full drilling capabilities, as well as workover and sidetrack capability on the topsides.

It operates at a depth of 1,585m and has a production capacity of 75,000 barrels of oil and 25 million cubic feet of natural gas per day.

The facility was built in Asia, while integration was performed in the US.

The ETLP has push-up type tensioner systems, which allow it to withstand the harsh conditions of the area. FloaTec is a contractor for the ETLP and conducted model tests of the ETLP, which indicated that it would be able to withstand a 1,000-year hurricane.

Pipeline

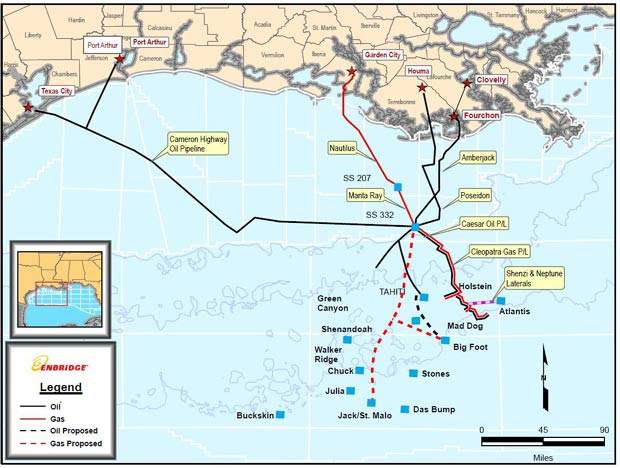

In October 2009, Enbridge signed a letter of intent with Chevron, Statoil and Marubeni to build and operate the Big Foot oil pipeline from the Big Foot field.

The 40 mile-long pipeline is located approximately 170 miles south of the Louisiana coast and lies in water depths of up to 5,900ft.

The pipeline is 64km-long and contains a 20in diameter pipe and is able to transport approximately 100,000bpd.

Enbridge undertook the $200m oil pipeline project as part of its Walker Ridge Gas Gathering System project to transport oil from the offshore fields in the Walker Ridge region to an onshore gathering system in Louisiana.

Big Foot contracts

In July 2008, INTEC Engineering was awarded a contract for carrying out a pre-FEED study for the project.

The company provided various development options for the field. The pre-FEED study was carried out for all subsea systems including wellheads, trees, umbilicals, and subsea control systems.

Chevron granted a FEED contract to KBR in November 2009 for the proposed Big Foot production facility. Work under the contract included development of the process design of the facility, structural analysis, and layout. KBR also determined the equipment required for the facility and designed the power generation and distribution system.

In January 2011, KBR was awarded another contract for providing the detailed design for the topsides of the Big Foot ETLP. KBR also provided engineering and procurement services under the contract.

Gibson Applied Technology & Engineering (GATE) was awarded a contract in October 2009 to provide its services during the FEED stage of the production facility.

As part of the contract, GATE designed chemical injection system and assisted in the selection of chemical vendors. It also provided overall health, safety and environment support and help in selecting ballast and potable water system material.

In December 2009, FloaTEC was awarded a contract to carry out FEED study for the hull, mooring, spars, and risers of the production facility.

FloaTEC provided overall project management services and developed designs for the hull, foundation piles, and risers of the facility. It also assisted in estimating the cost of the facility.

ABS carried out the design review for the ETLP and conducted classification approvals, equipment fabrication, and installation surveys.

In February 2011, 2H Offshore won a contract to supply riser systems for the field. The company was responsible for the design, manufacture, and installation of two high-pressure drilling risers, 15 production / water injection top tensioned risers, and oil and gas export steel catenary risers.

A detailed design contract for the Big Foot pipeline was awarded to Foster Wheeler in March 2011. Dril-Quip won a contract in the same month to provide drilling equipment for the field.

In May 2011, Baker Hughes was contracted to provide electrical submersible pumping systems for the field’s production wells for enhanced recovery of hydrocarbons.

GE Oil & Gas’s Drilling & Production division was awarded a $45m contract in July 2011 to supply marine riser tensioner system for the ETLP.

Chevron contracted Wood Group in July 2011 to undertake commissioning of the ETLP.

Nabros provided the deepwater drilling rigs for the ETLP installed at the project.

Promat Marine provided the acoustic and fire-rated linings solutions for the fire-protection systems installed at the Big Foot development project.